Etching

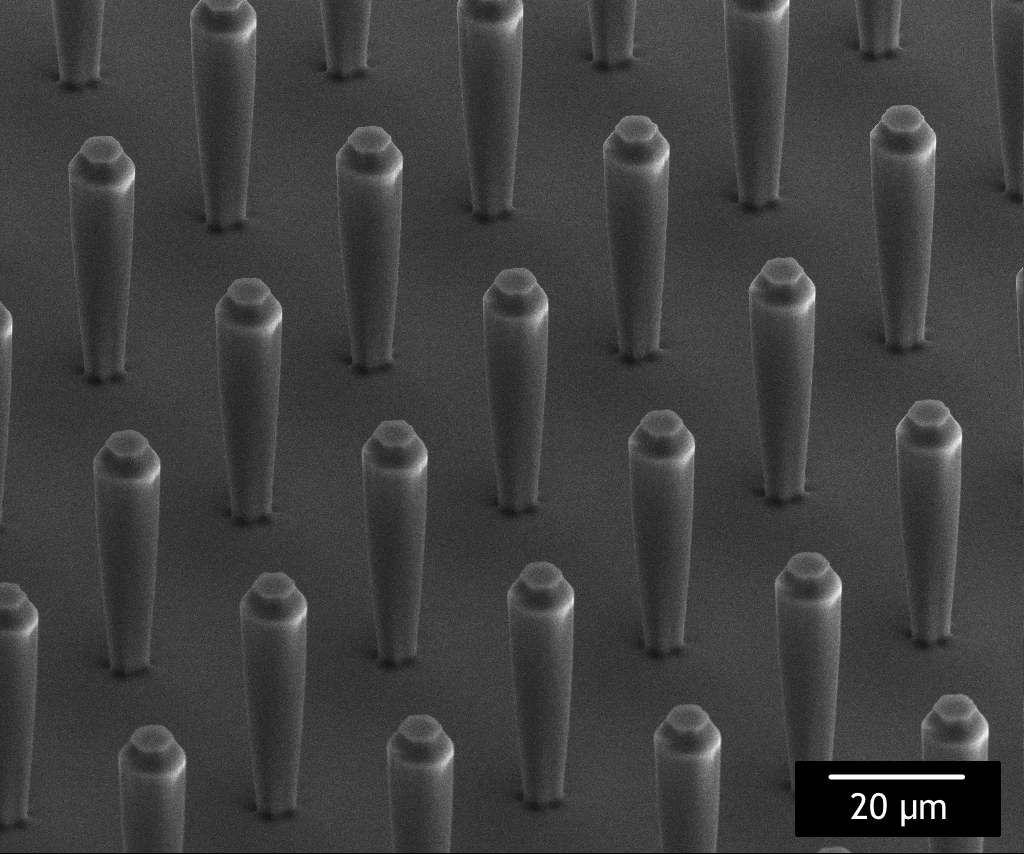

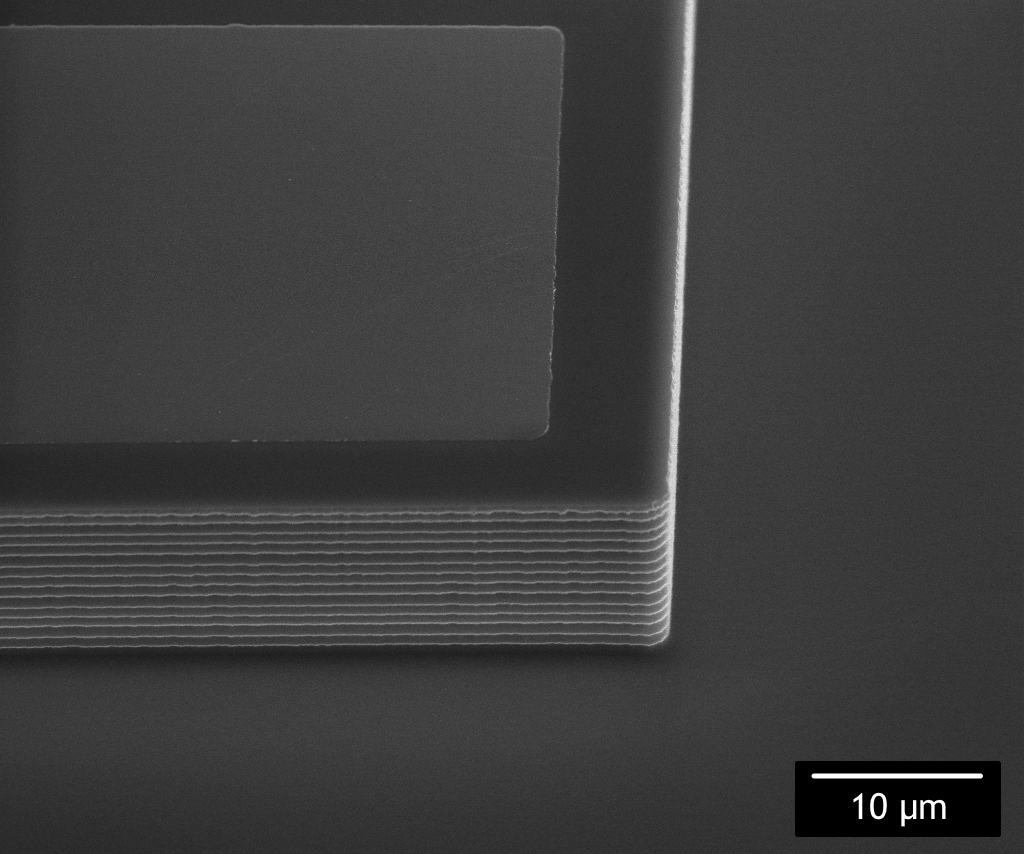

Microfabrication etching technology provide engineers and scientists with a means to remove materials with atomic precision. Chemical etchants are selected to rapidly etch one material while slowly etching another. This contrast enables a pattern from a thin stencil to be transferred deep into a material. Against chemically resistant material, a heavy noble gas such as argon can be blasted at the material to erode its surface.

Etching is often combined with lithography and deposition to provide material contrast. For example, a 25 [nm] thick patterned chromium film can be etched into quartz to form 500 [nm] tall structures to be used for molding. This process allow nanoscale structures to be produced using a variety of materials depending on the desired function.

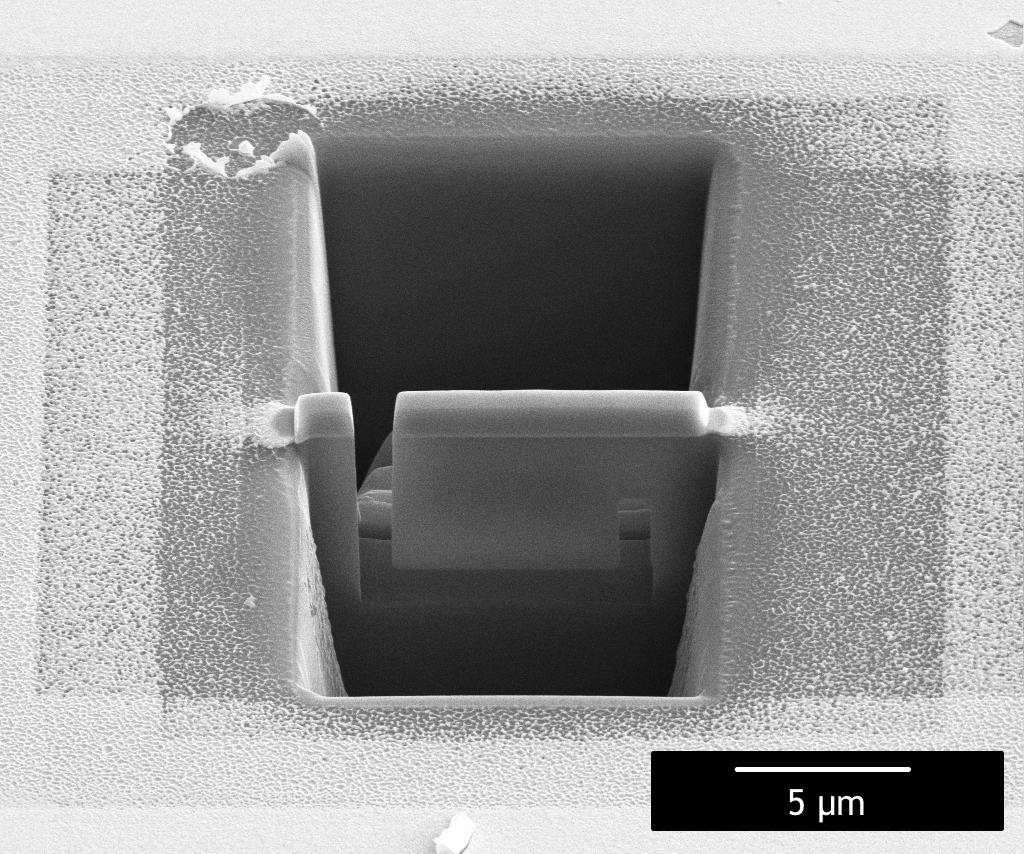

Reactive Ion Etching

Reactive ion etching uses a gas to chemically etch a material. The gas is ignited it into a plasma which dissociates the gas molecules into its constituent atoms, ionizes and direct them towards a sample. The ionized atoms then reacts with the sample material to form a volatile product. The gas composition and sample material are matched to ensure that the sample evaporates away.

Reactive ion etching can be very selective, etching one material up to 150 times faster than a masking material. In addition, deep and straight trenches with aspect ratios of up to 20 is achievable.

Ion Milling

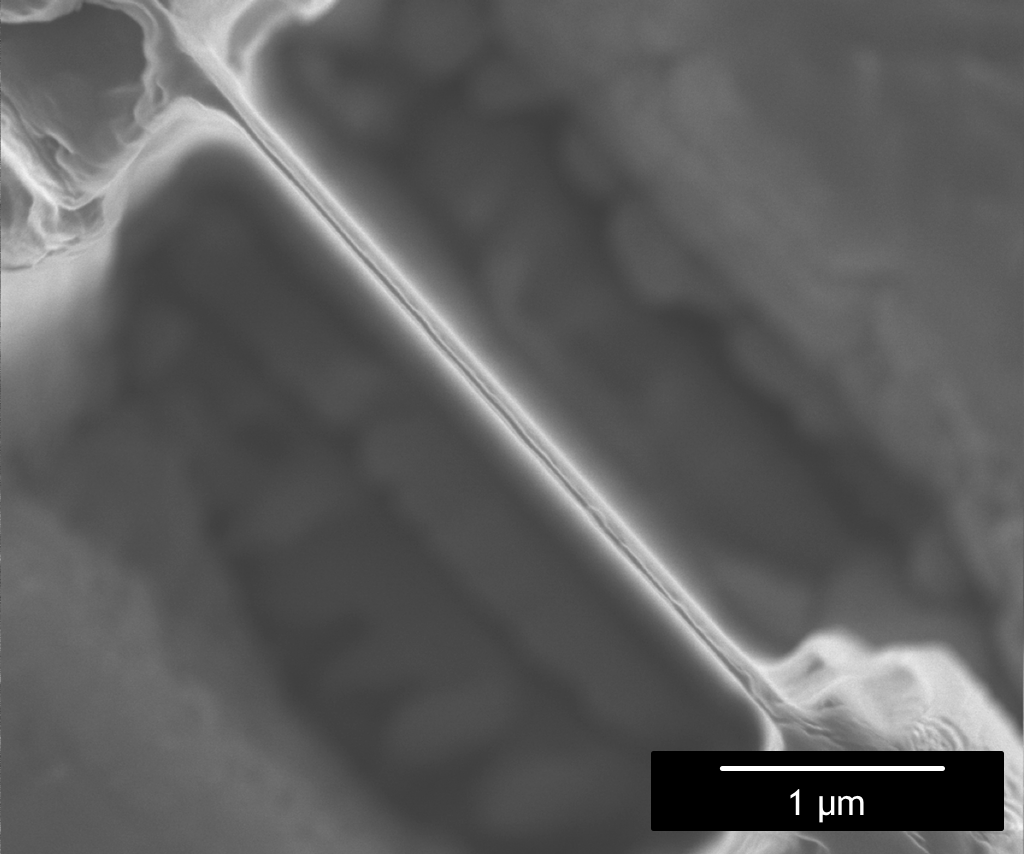

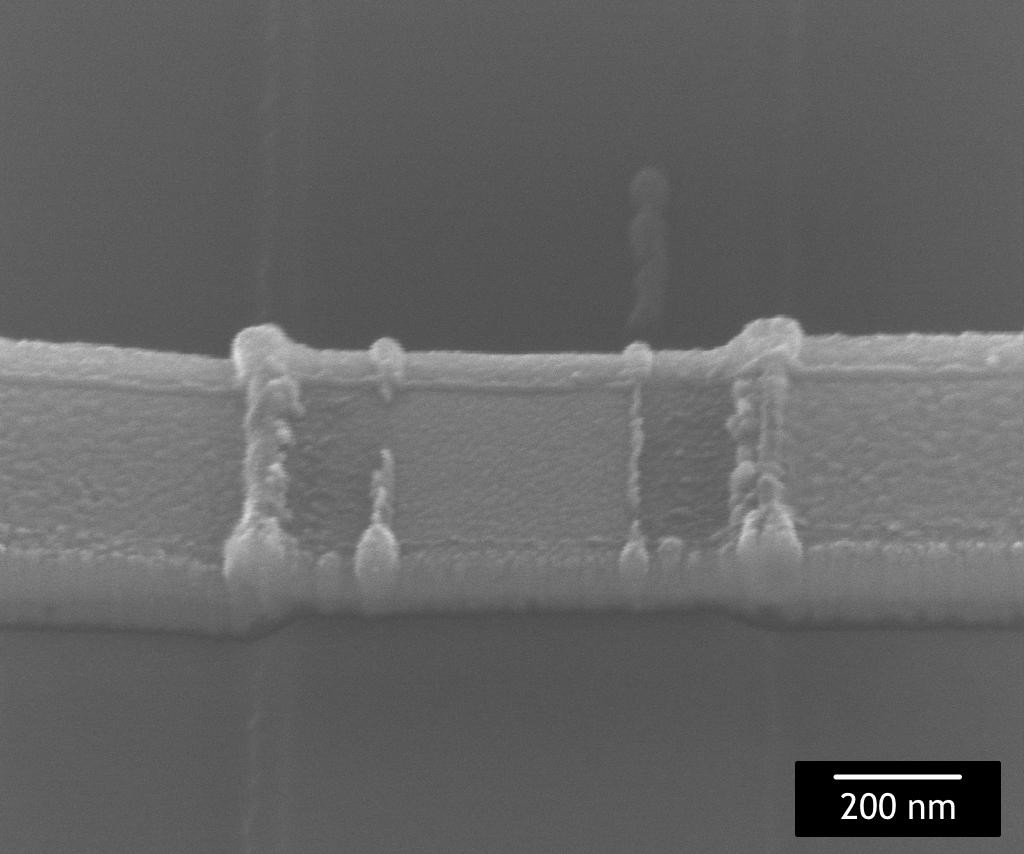

Ion milling uses argon to physically erode a material. Argon gas is ignited in a plasma, ionized and accelerated to bombard the material. The momentous argon atoms slam into a target material to eject its surface atoms. Argon does not contaminate the material because it does not form compounds with any element. Ion milling can be used to erode away any material.

Ion milling erodes most material at a similar rate. This method is often used as an alternative to reactive ion etching.

Wet Etching

Wet etching uses a liquid to chemically etch a material. The constituents of the liquid reacts with the material surface to form a compound which dissolves away.

Wet etching can be very selective, etching one material without etching the masking material.

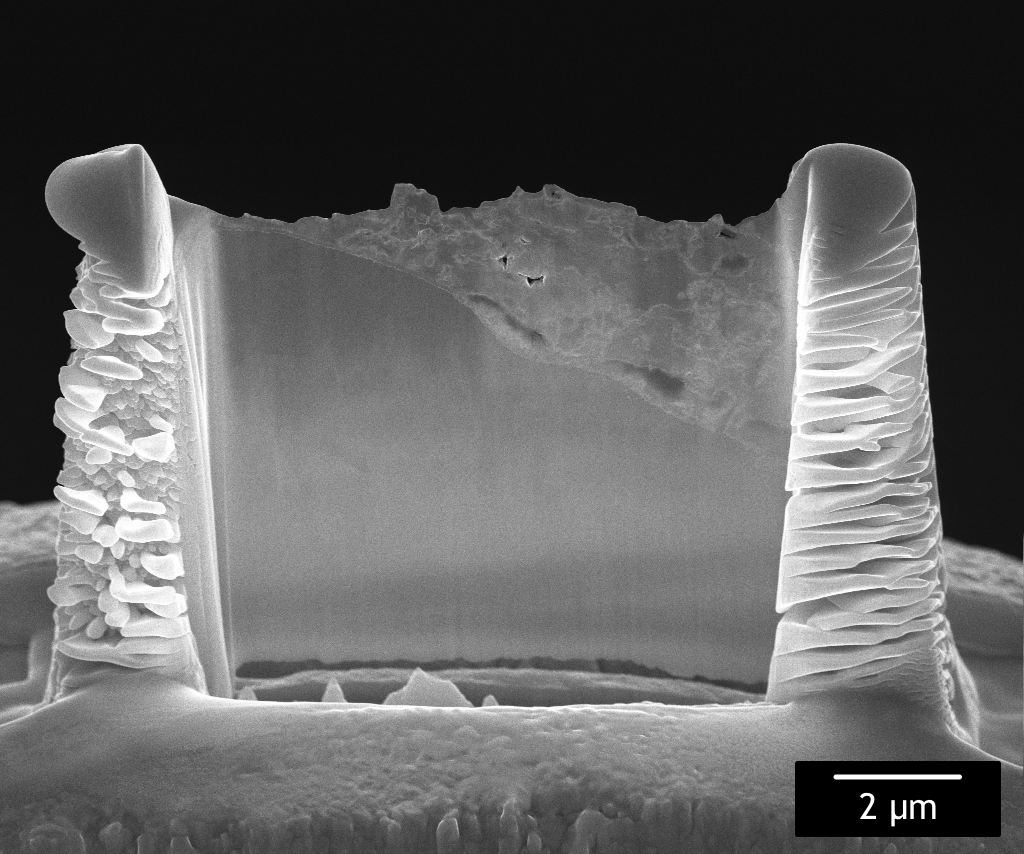

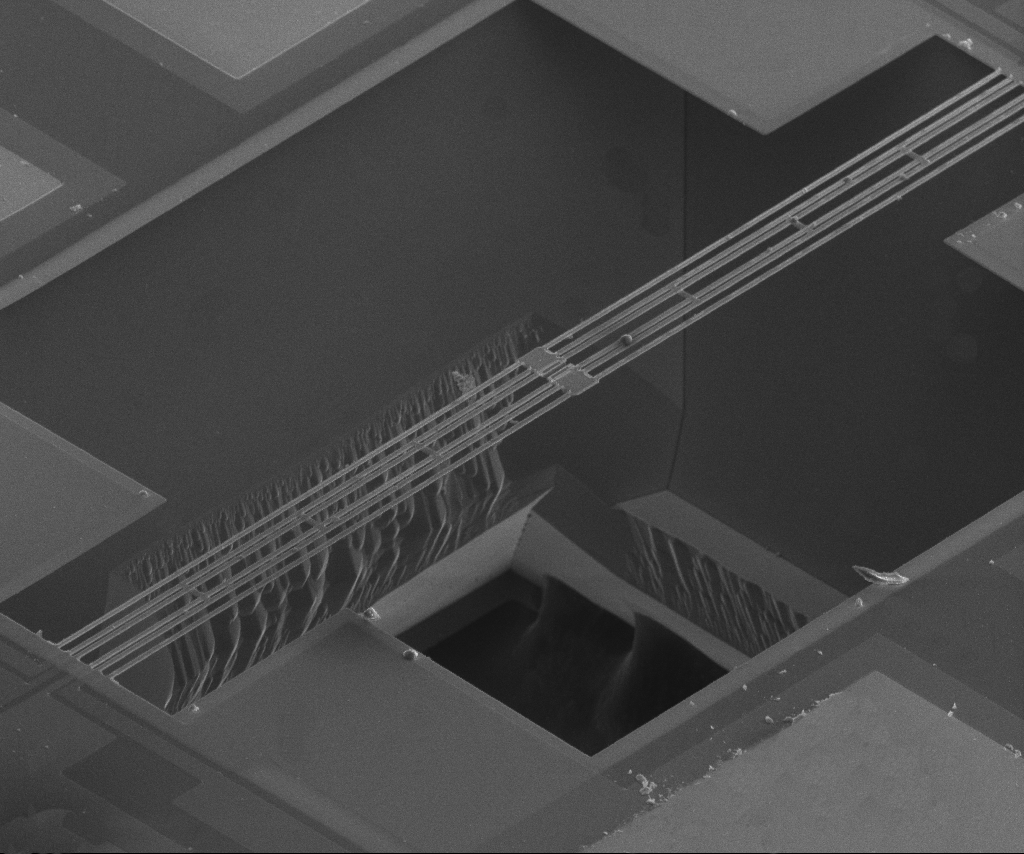

Focused Ion Beam - Milling

Focused ion beam erodes a material by bombarding it with a focused beam of gallium ions. The momentous gallium atoms slam into the material to eject its surface atoms. The 10 [nm] wide beam can be scanned to erode away a specified pattern in the material.

Focused ion beam milling typically used to cut out sections of a material for inspection with an electron microscope. It can also be used to mill microscopic structures or polish surfaces.