Technology Development

Microfabrication facilities are state-of-the-art research infrastructure that demands excellent scientists, engineers and technicians to support research and engineering at the ever progressing frontier of science and technology. New researchers can progress further and faster when their predecessors provide a firm foundation of technology. UHNF highly encourages and supports the development of new core technology that is shared openly.

Core Technology Development

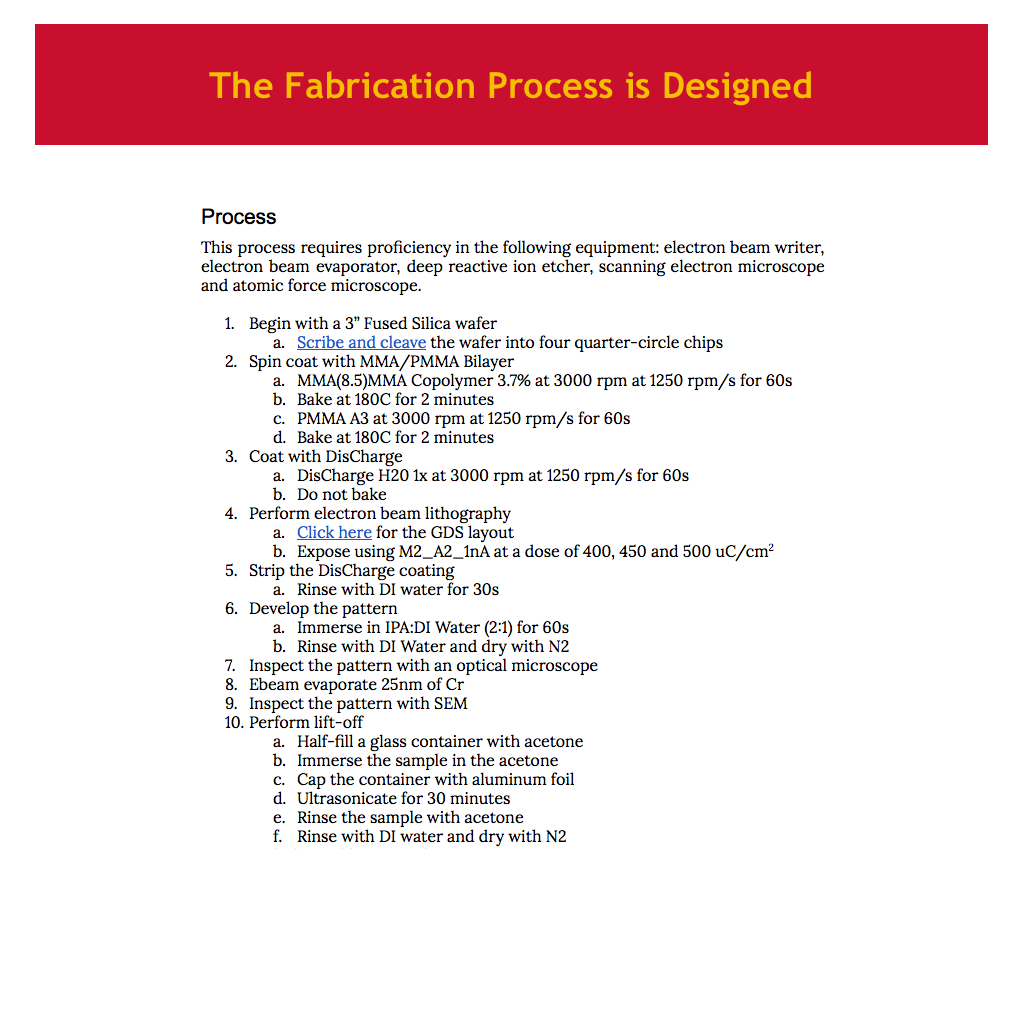

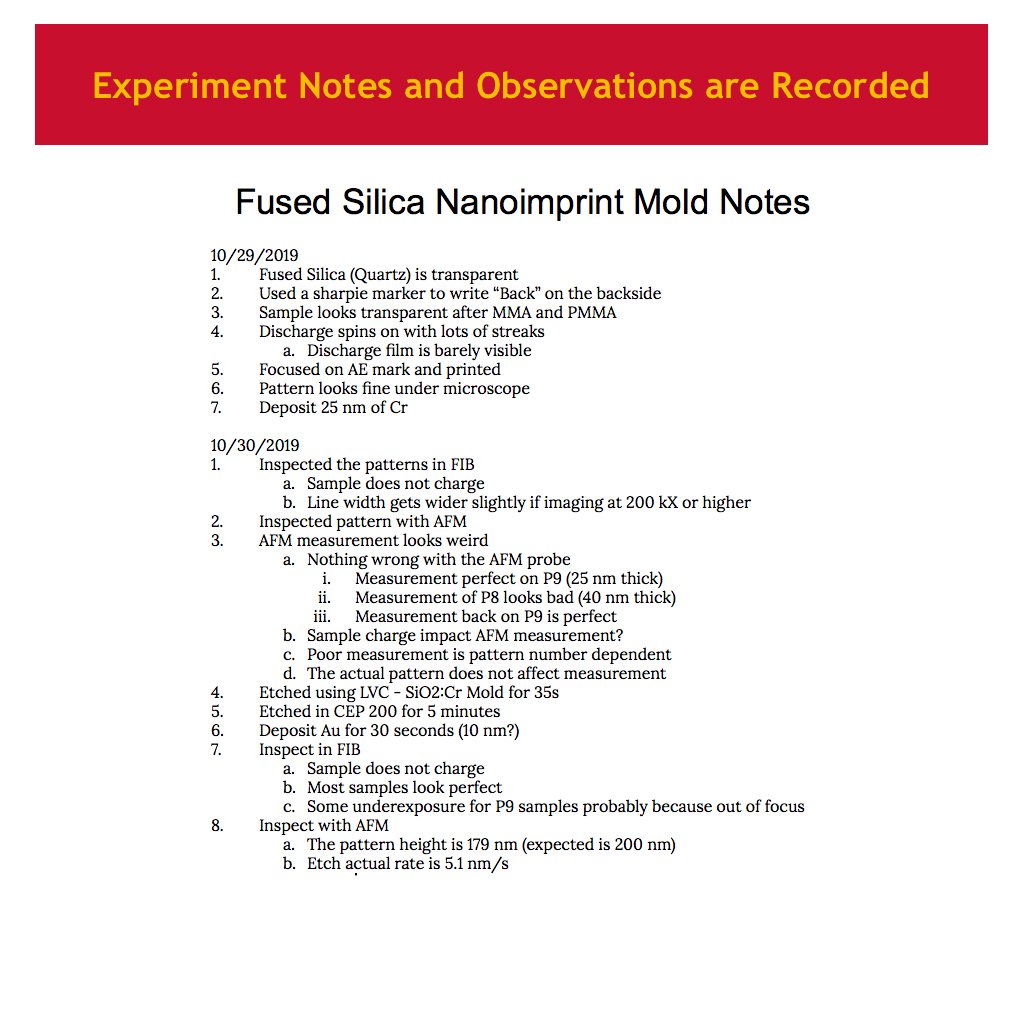

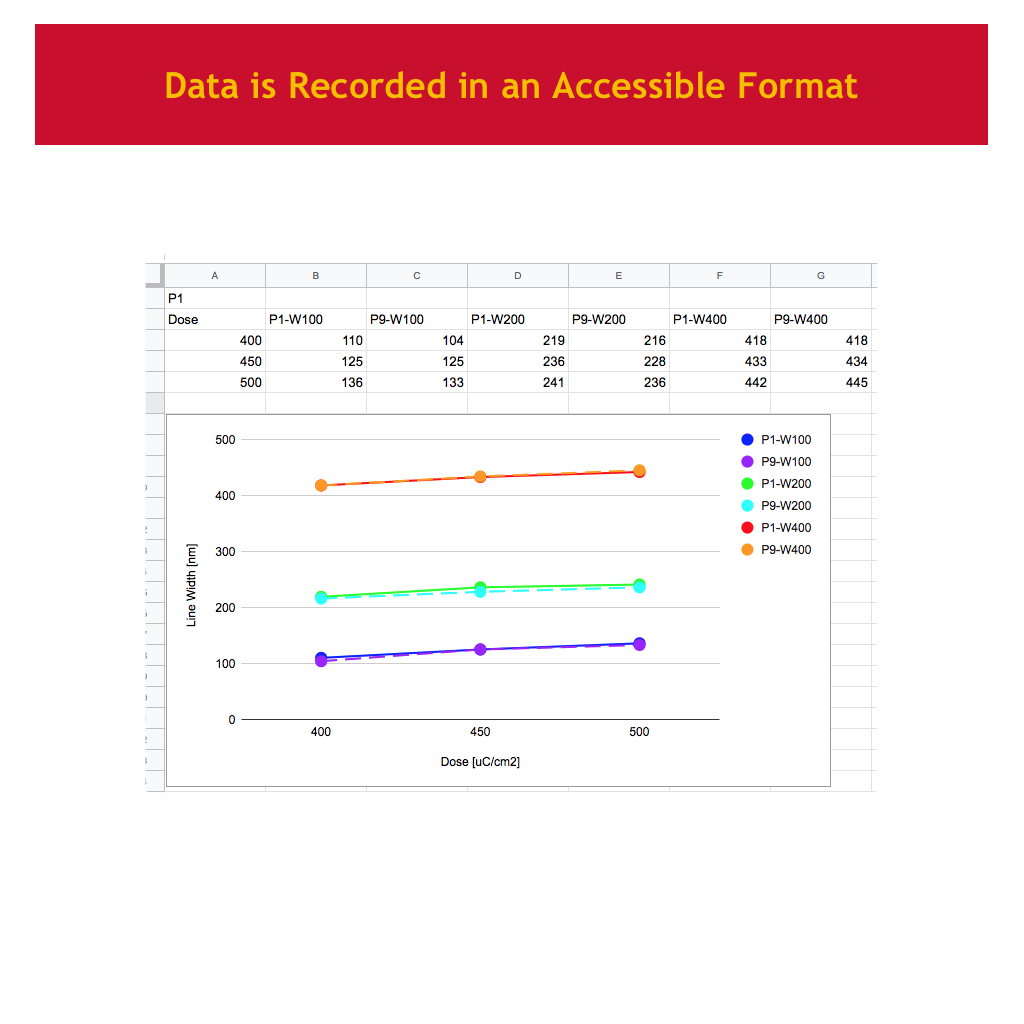

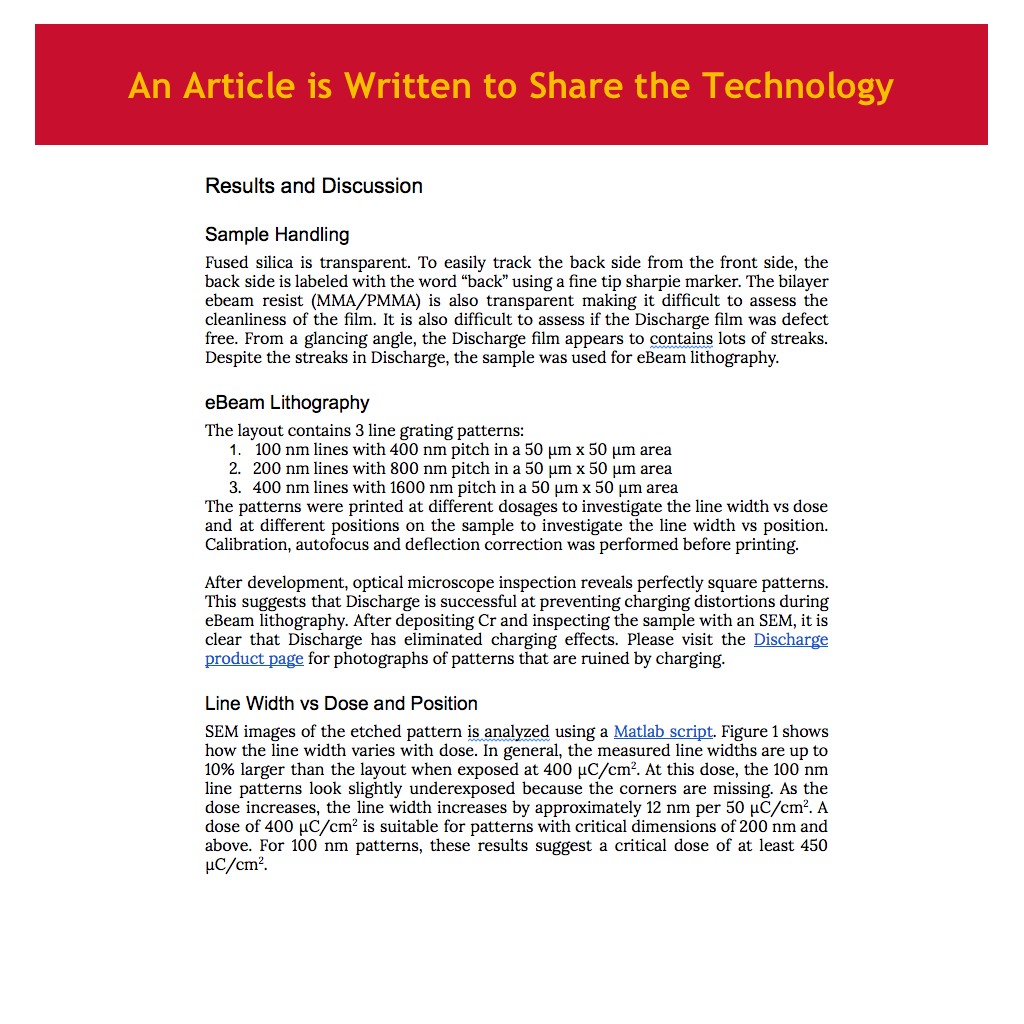

A research infrastructure without core technology is simply a repository of equipment where researchers are trained in basic operation and are left to figure out what to do on their own. The learning curve for new researchers can be greatly reduced with a bit of guidance from local experts and a set of core technologies. Synergistically, expertise is acquired naturally through developing high quality core technologies. A single core technology can take an experienced professional weeks, months or years of effort to develop, but it should be able to be repeated by a new researcher within a single experiment by following documented procedures or a single training session.

Core technology projects are pursued based on need and the anticipated benefit to the community. Many researchers have been able to pursue their projects utilizing mostly UHNF core technologies, producing results sooner while spending fewer resources. We have also collaborated with researchers to accelerate the development of core technologies necessary for their projects. Contact us if you’re interested in our core technology development service.

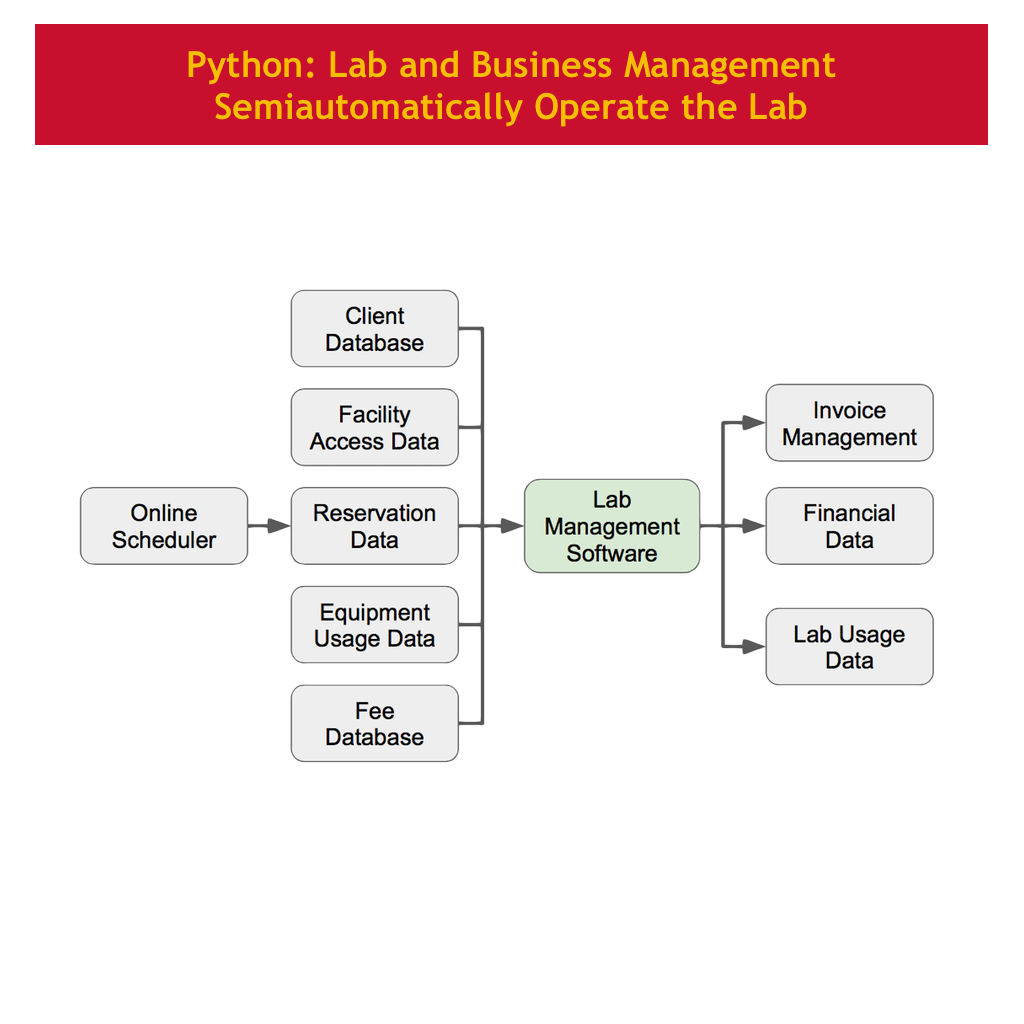

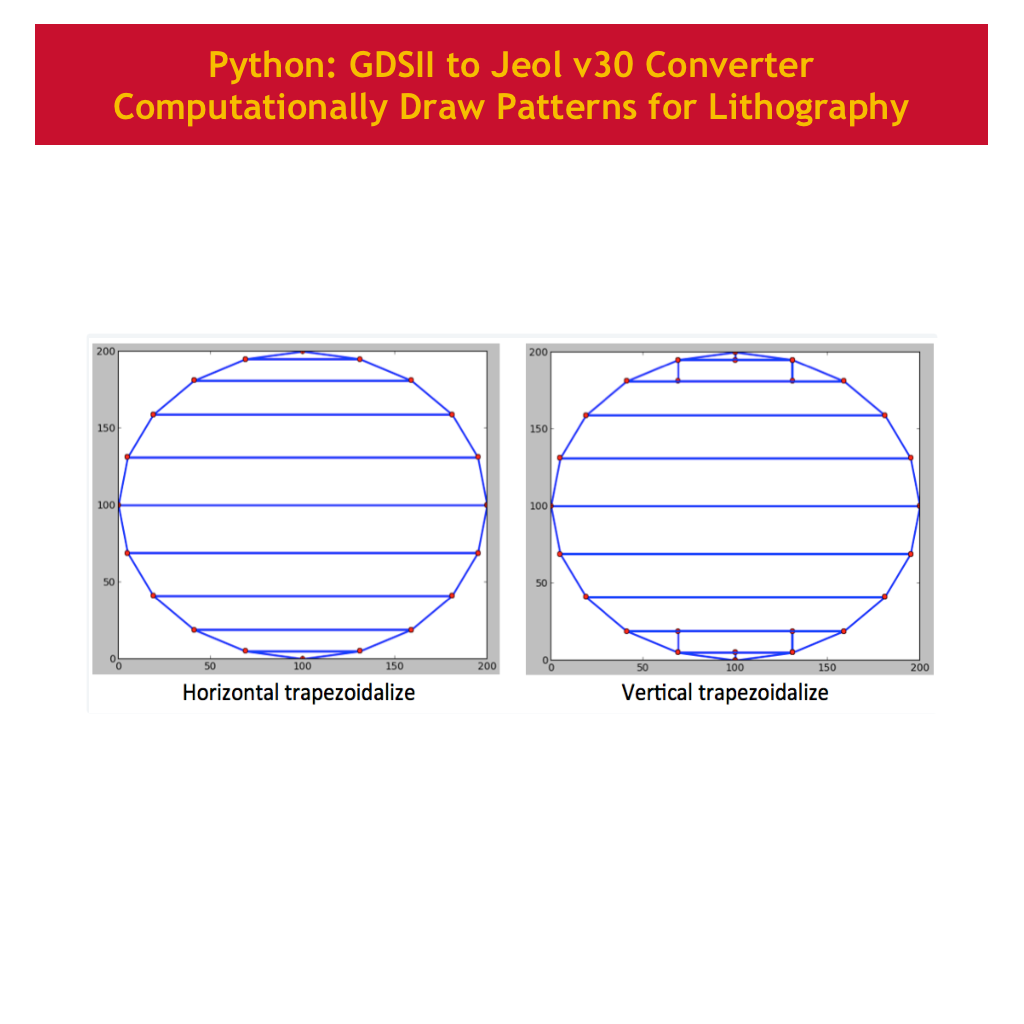

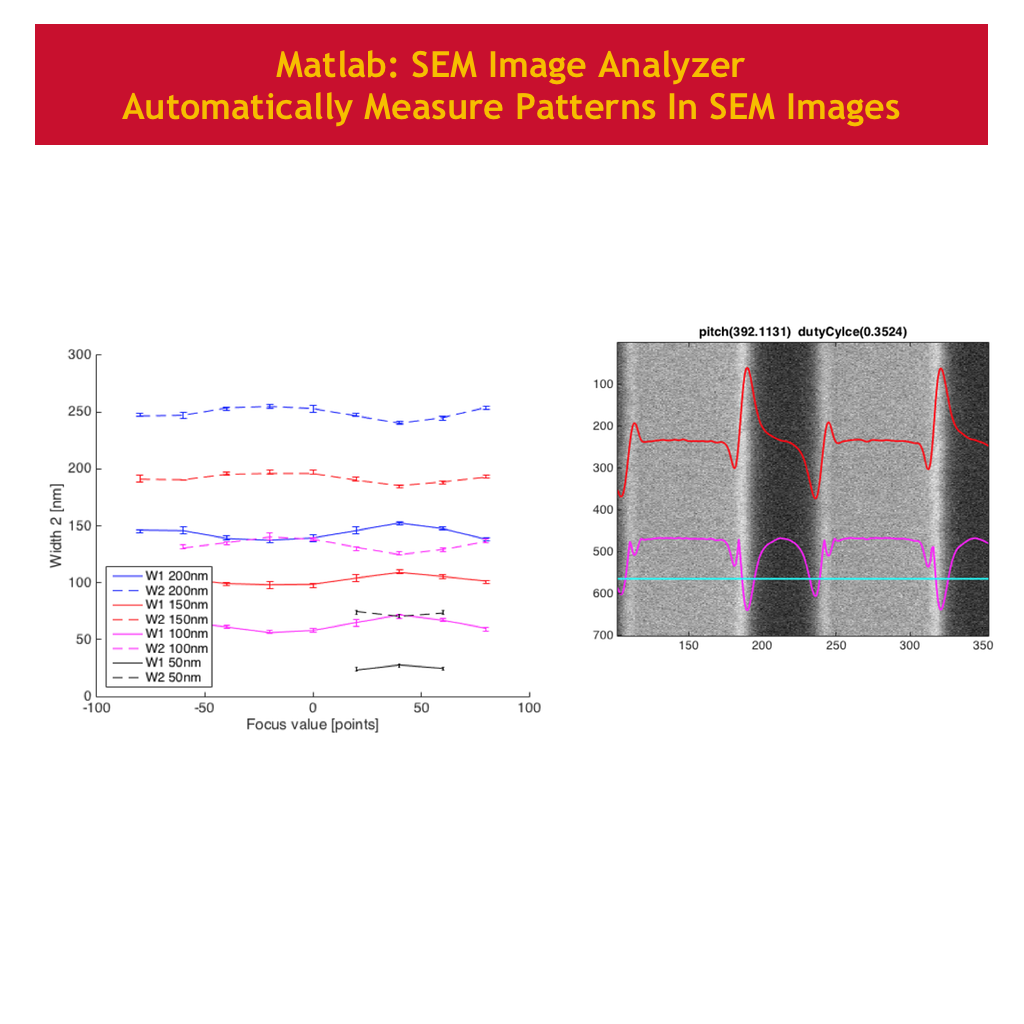

Software Development

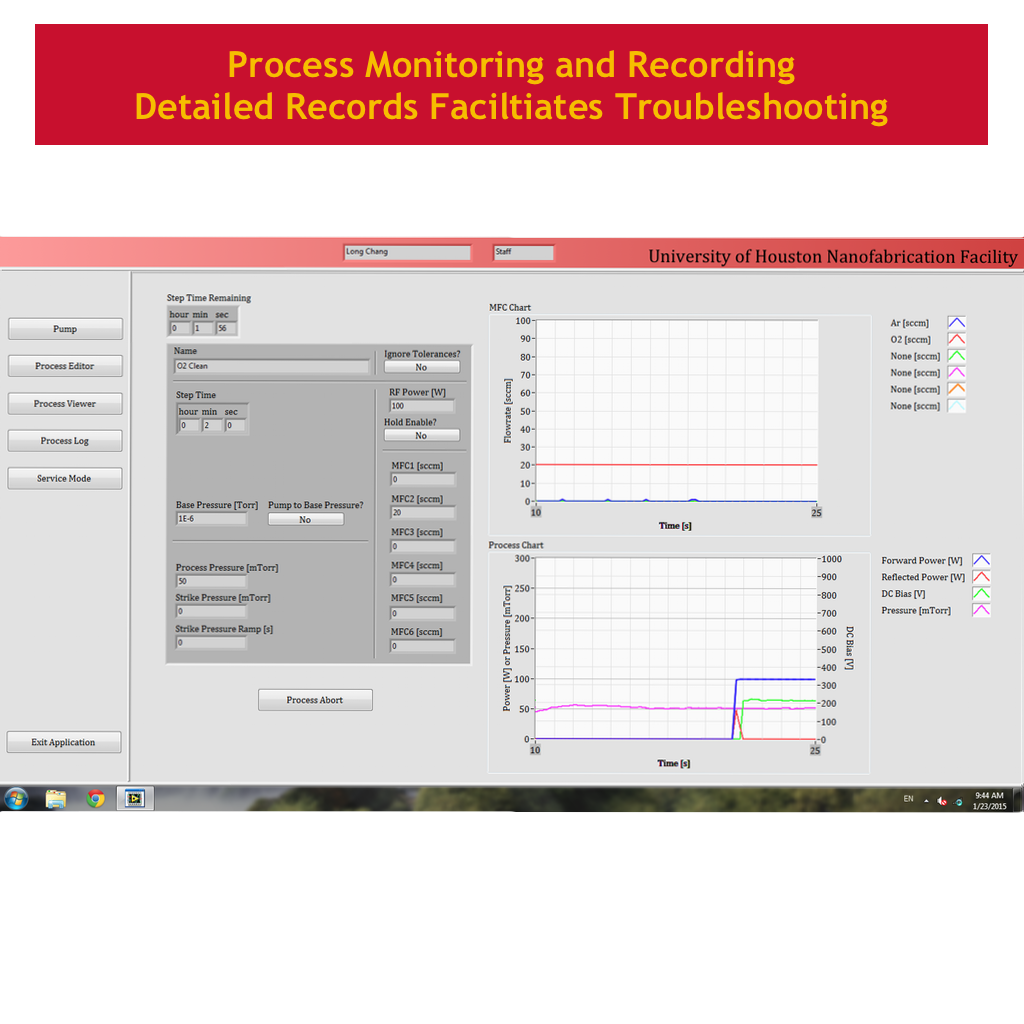

In a productive environment, tasks are engineered to be repetitive and procedural. Then software is developed to automate these tasks. Although the cost of development may be daunting, the return on investment can be astronomical. A good piece of software can be copied and distributed for free, providing potentially infinite value. Software and automation technology development has lead to improved research productivity and significantly reduced the cost of lab operation.

A number of software applications have been developed to control scientific equipment and instruments, analyze large quantities of research data and flawlessly process financial data. As the end user, maintainer and developer, we can take a very holistic approach to design and engineer software that is easy to use, easy to maintain and easy to update. Contact us if you’re interested in our software development service.

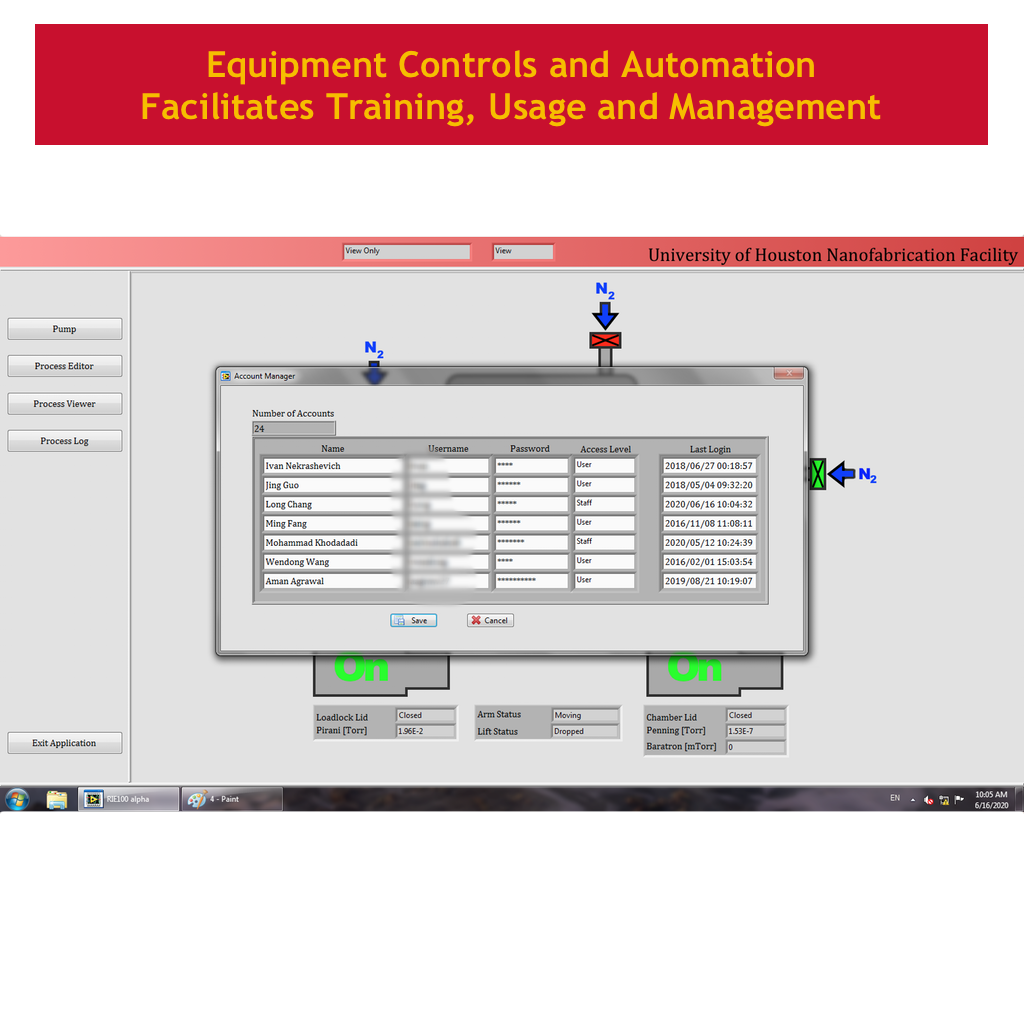

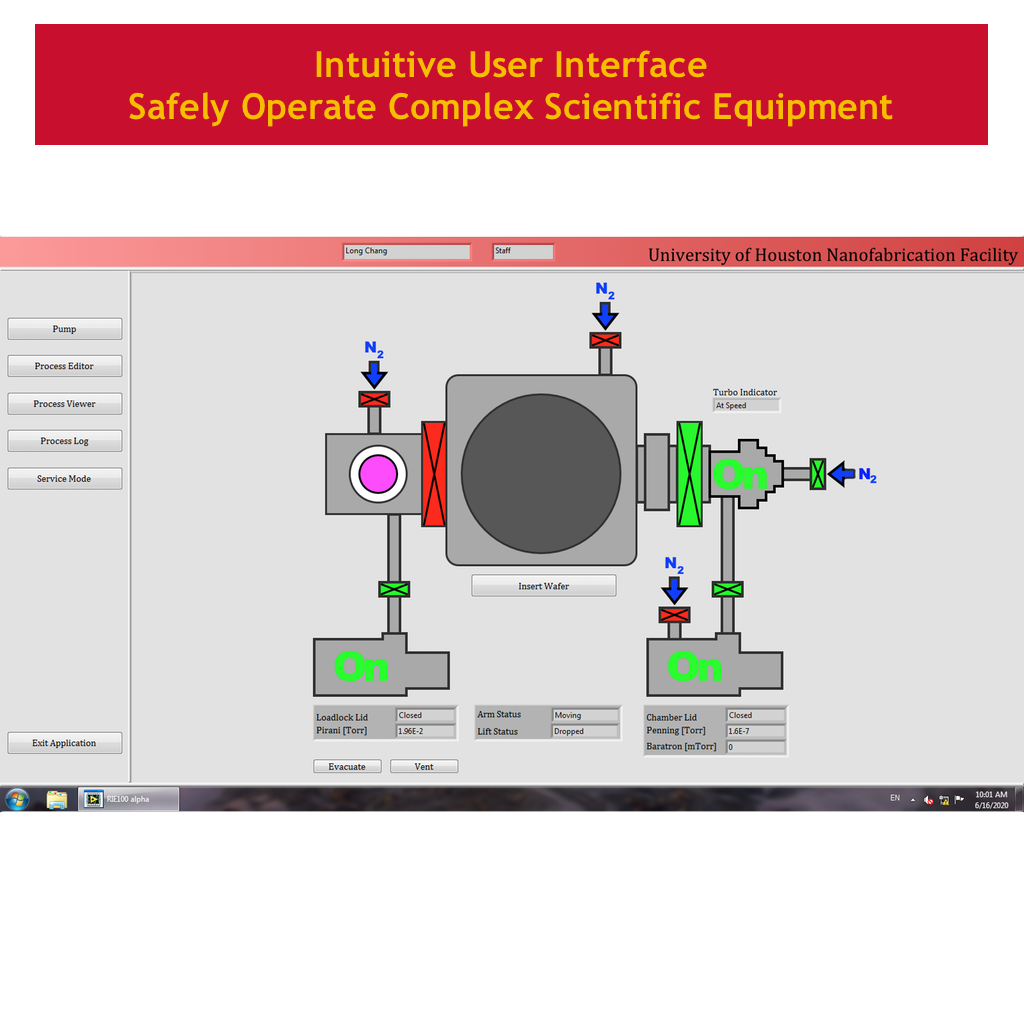

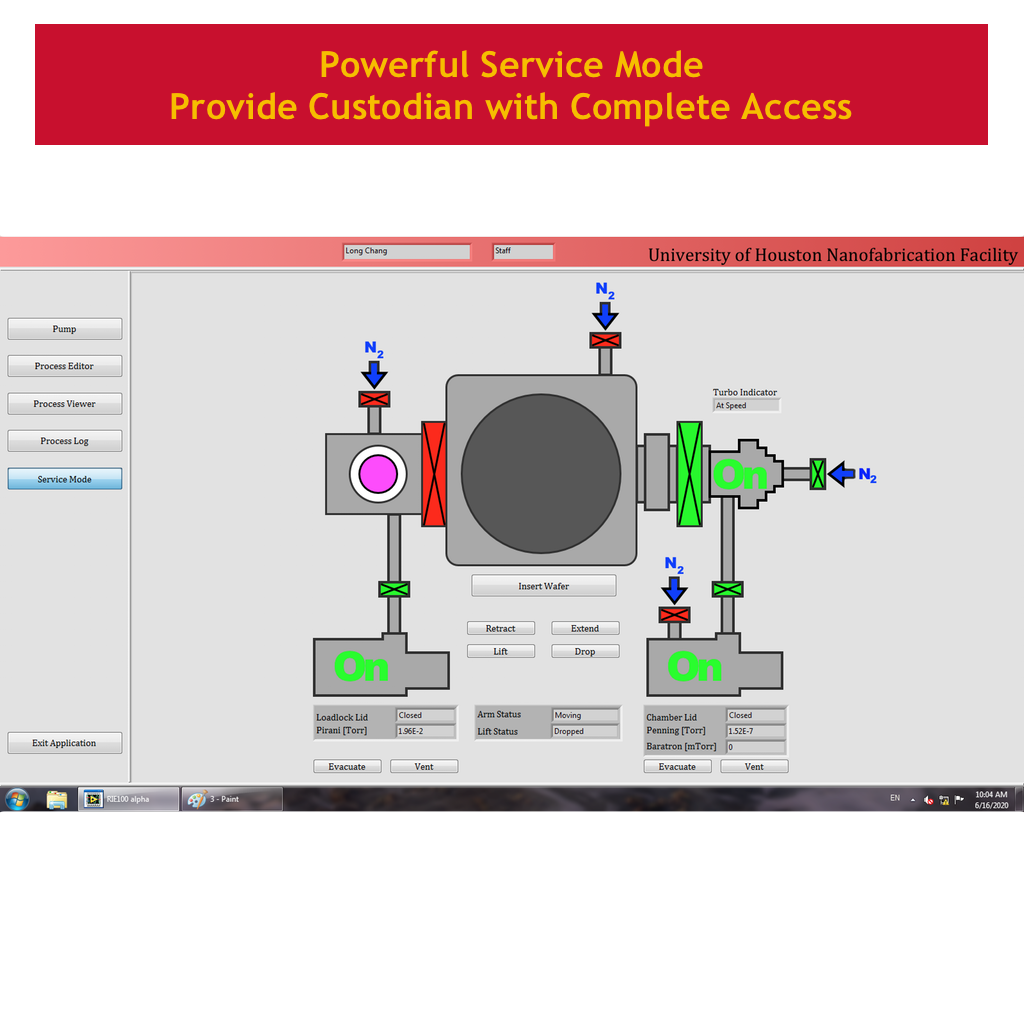

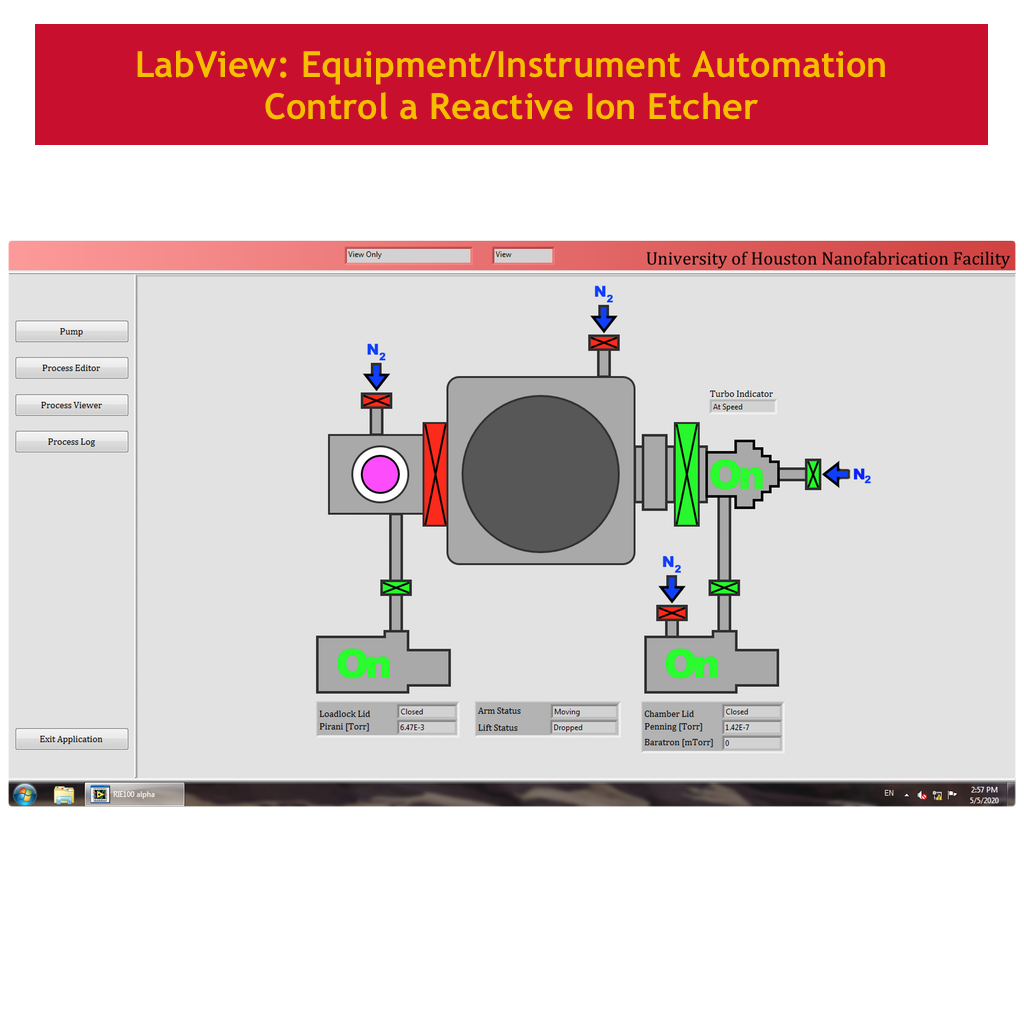

Equipment Controls and Automation

Operating scientific equipment manually can be very educational providing students and researchers with opportunities to learn how things work. Hidden behind the veil of a modern computer interface is a network of switches and actuators that needs to be controlled in specific sequences. Unfortunately, manual controls quickly become cumbersome, is prone to operator error and provide very limited capabilities. Fortunately, the majority of operators who use equipment can get their job done without knowing what it does. This is achieved through designing a controls and automation system that balances the needs of operators, custodians, technicians, managers and developers.

Nanofabrication facilities contain all of the stakeholders of a scientific equipment. At UHNF, we have a single person who plays all the roles and understand their needs and capabilities. We have designed and developed many scientific instruments and equipment such as: Polar Magneto-Optical Kerr Effect (PMOKE), GMR Chip Tester, Scanning Magnetoresistance Microscope (SMRM), Magneto-electric Tester, GMR Module for an Atomic Force Microscope, and Reactive Ion Etcher (RIE). Contact us if you’re interested in automating your equipment.