Lithography

Lithography is used to produce stencils (or anti-stencils) in a printing media such as a thin film of polymer. The printing media typically does not provide any function to a gadget. Instead, the pattern in the printing media is transferred to other materials via deposition or etching. This allow nanoscale structures to be produced using a variety of materials depending on the desired function.

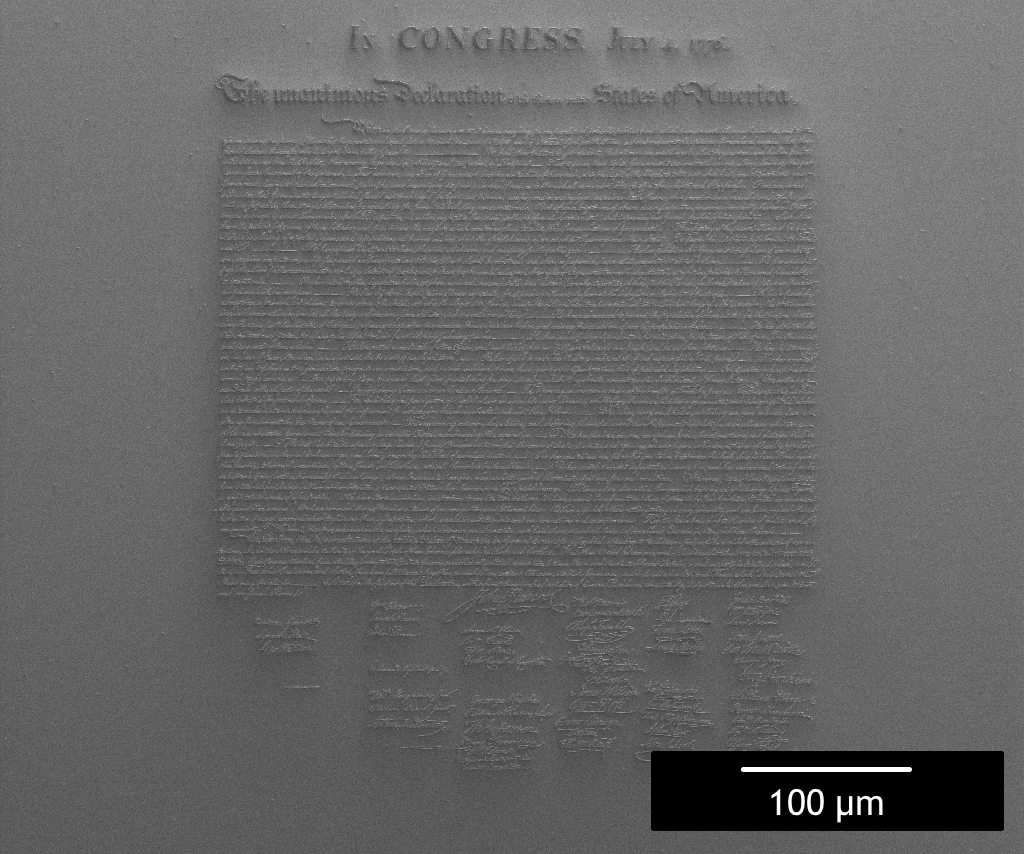

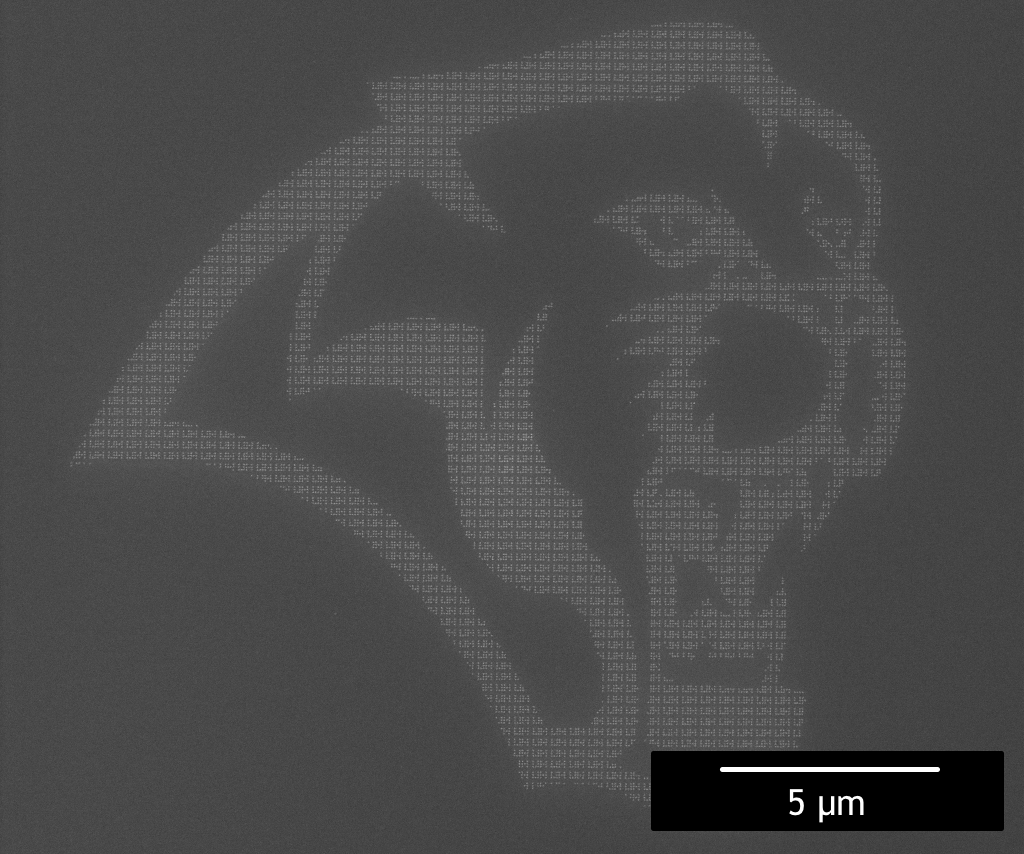

Electron Beam Lithography

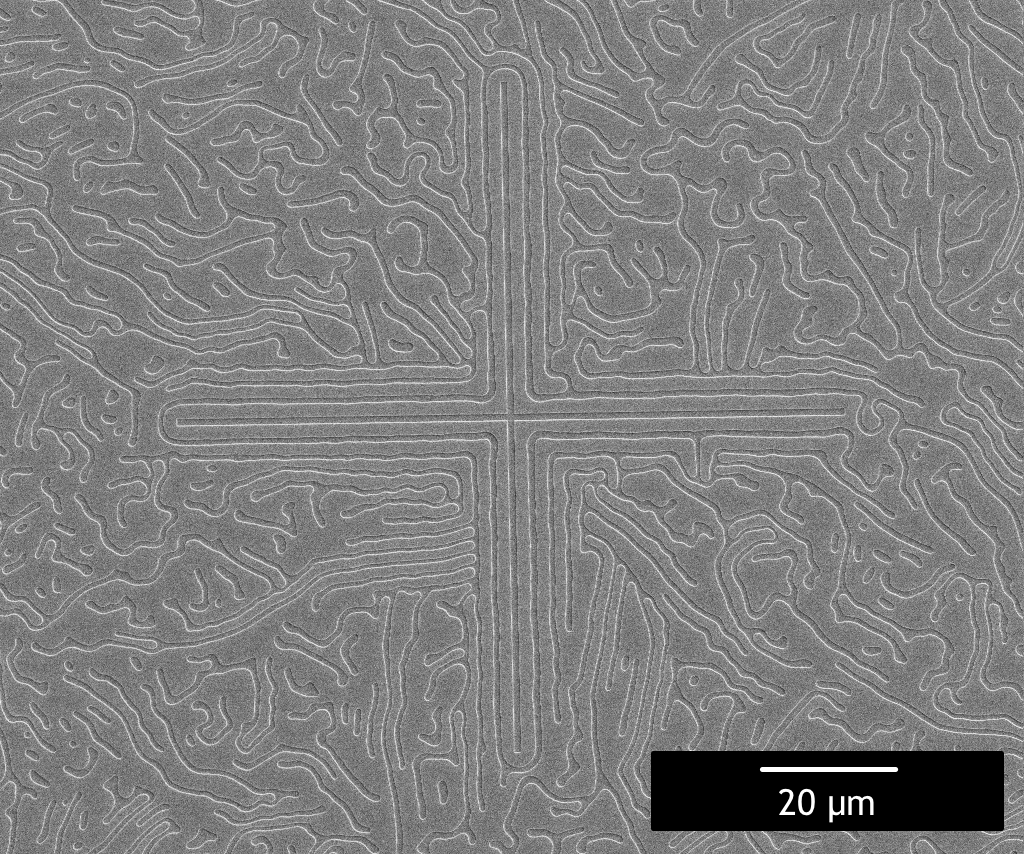

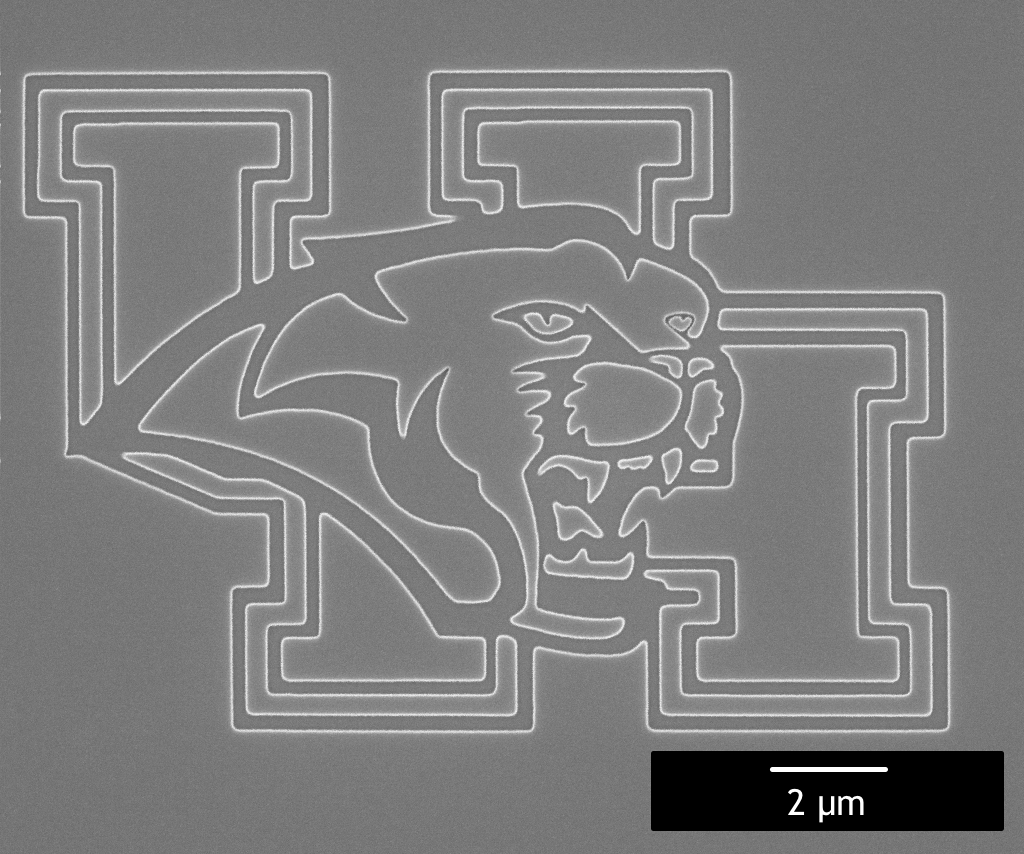

Electron beam lithography focuses electrons into a 5 nanometer spot to draw custom patterns in a thin film of media. The electron beam causes the dissolution rate of the media to significantly increase or decrease when immersed in a solvent. This phenomenon provides binary contrast that is used to make stencils (or anti-stencils) with 10 nanometer resolution.

Photolithography

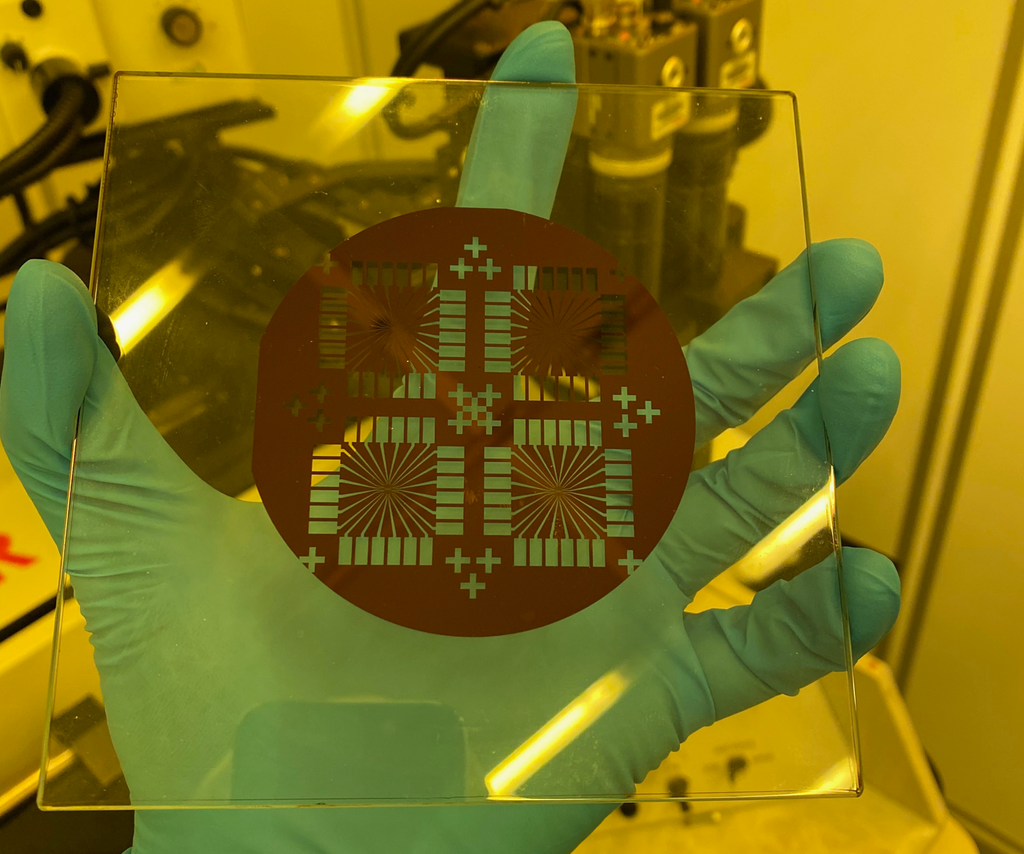

Photolithography uses a broad beam of ultra-violet (UV) light to replicate a binary mask pattern in a thin film of media. The binary mask has opaque regions that block the UV light and transparent regions that transmit the UV light. The UV light causes the dissolution rate of the media to significantly increase or decrease when immersed in a solvent. This phenomenon provides binary contrast that is used to make stencils (or anti-stencils) with 1 micrometer resolution.

Photolithography requires a binary mask which can be purchased from a company.

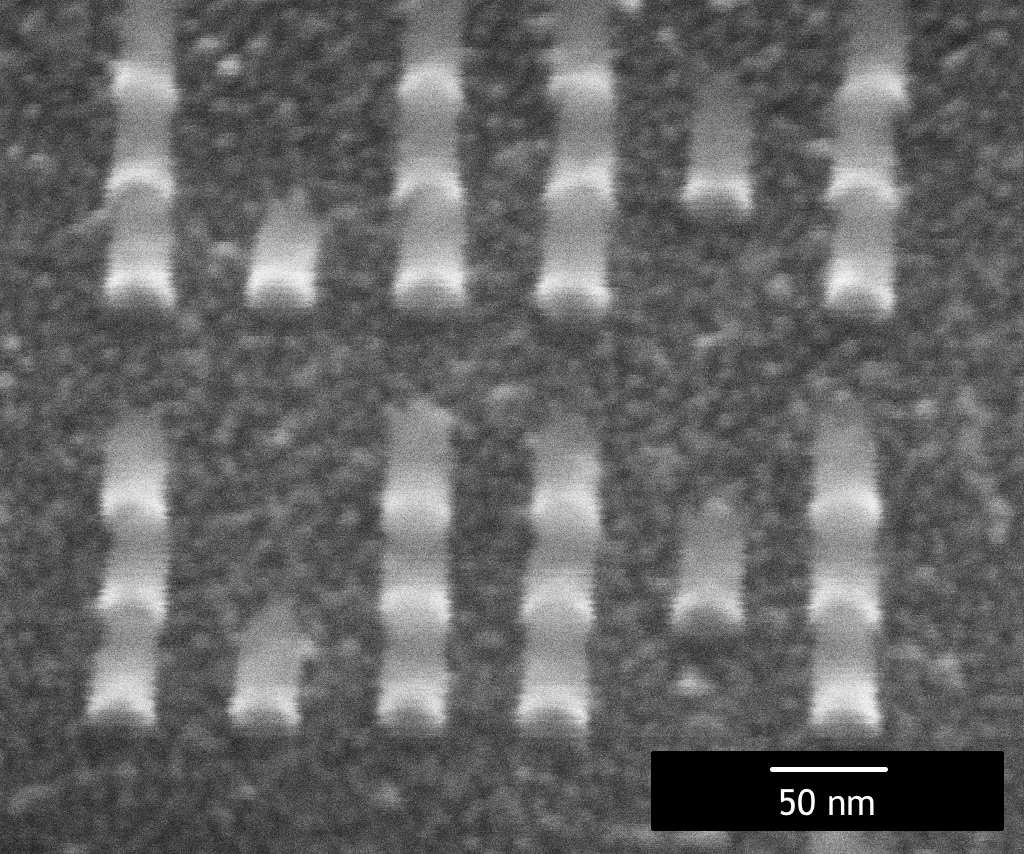

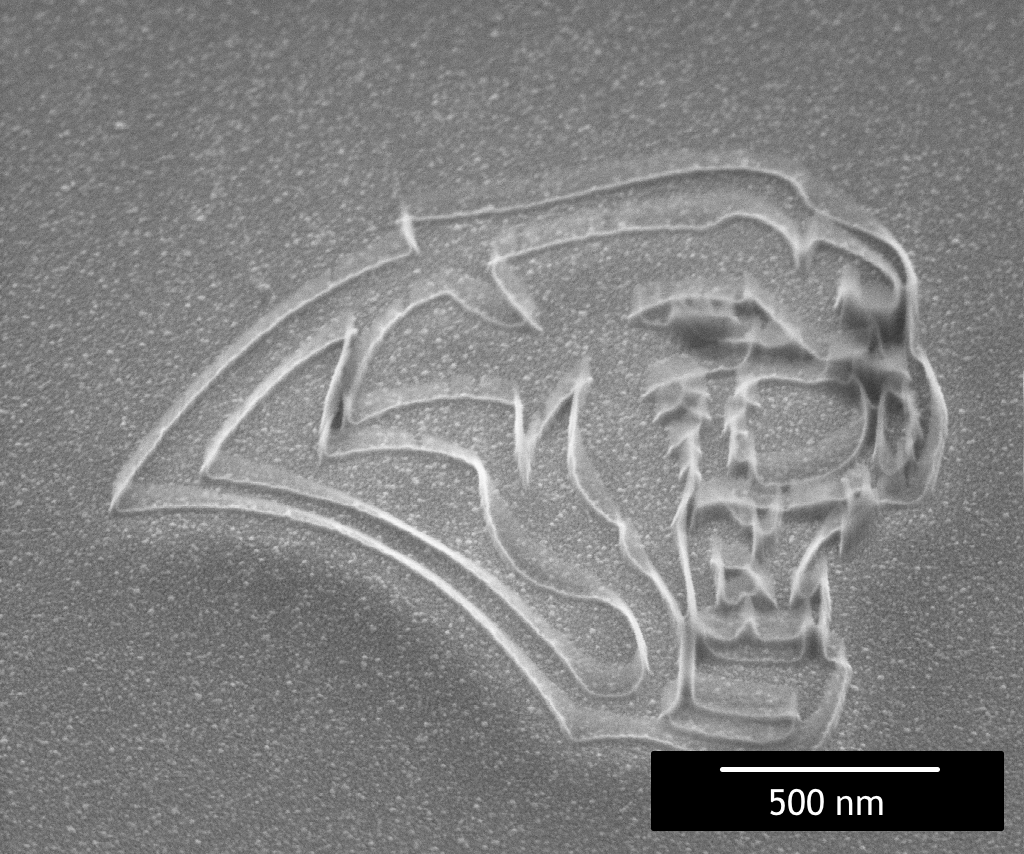

Nanoimprint Lithography

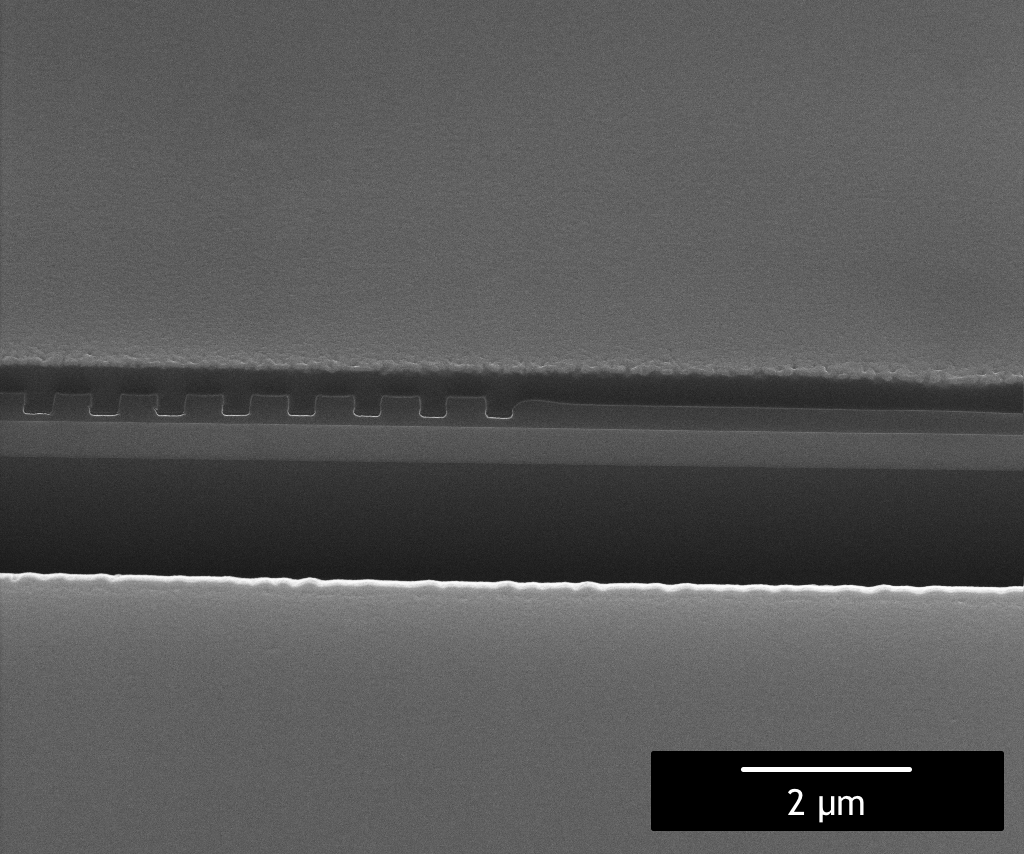

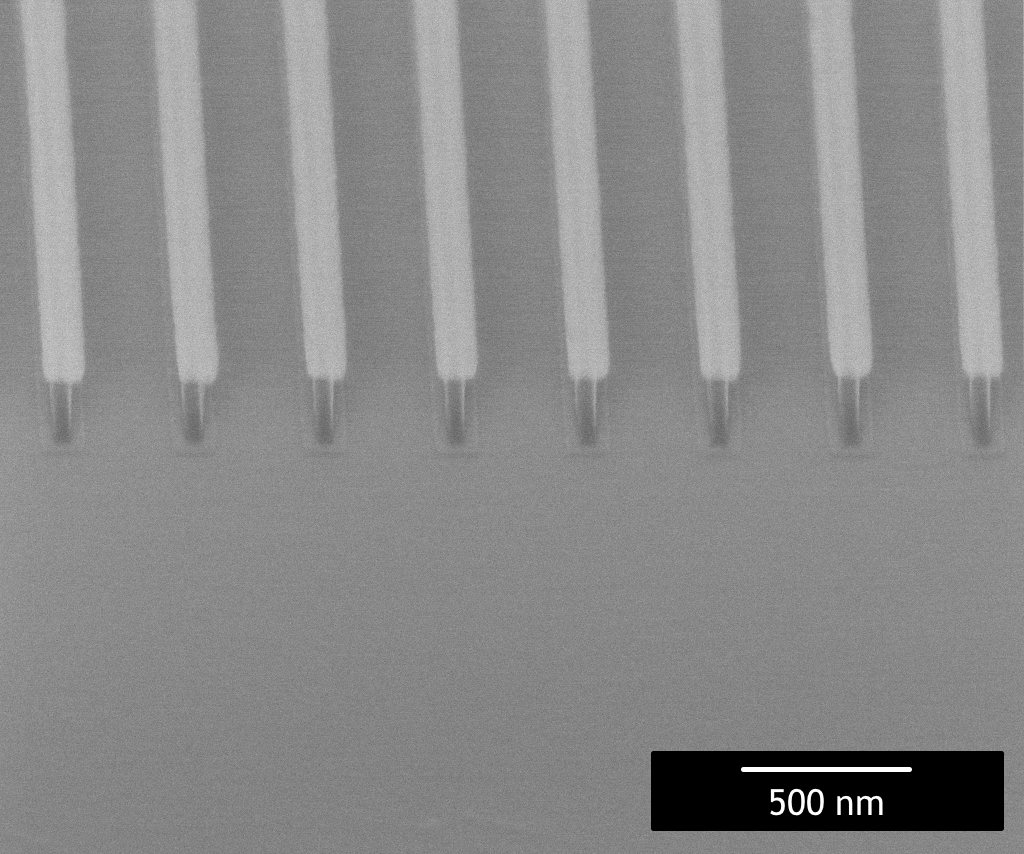

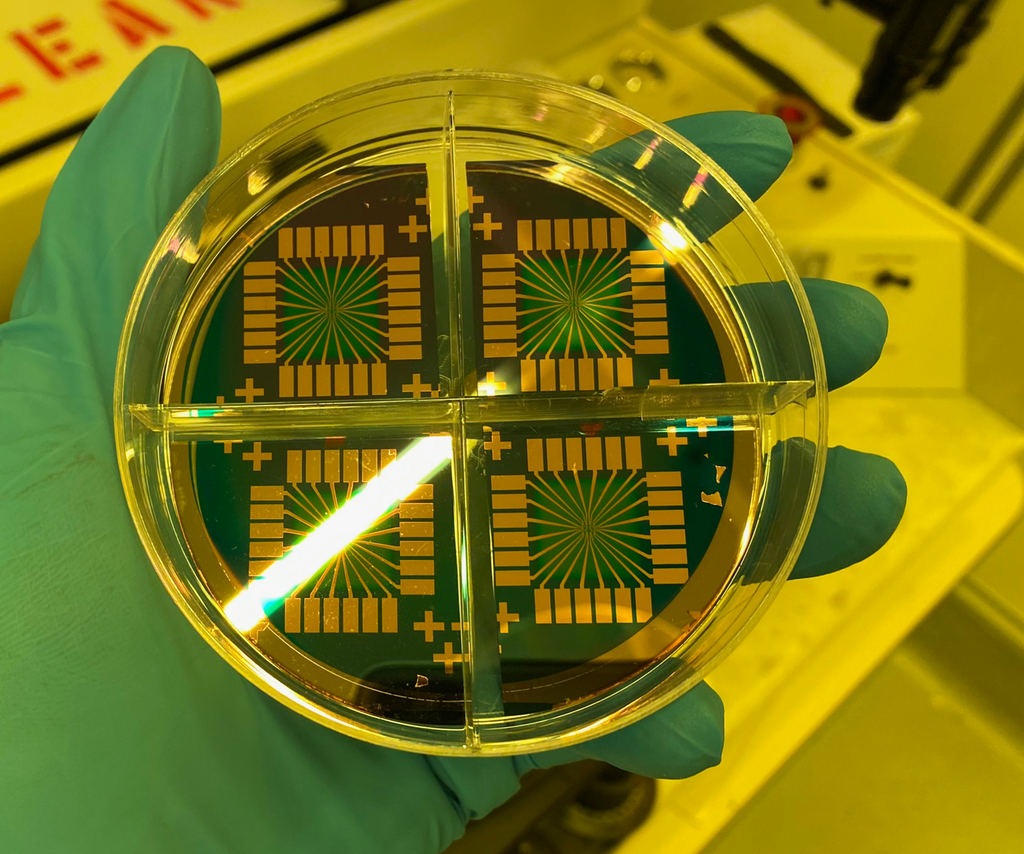

Nanoimprint lithography uses pressure and energy (heat or UV light) to replicate a mold pattern in a thin film of media. The mold has raised structures that displaces the media when pressed together. Heat is often used to soften the media to facilitate its displacement. When the heat is removed, the media solidifies into an exact negative replica of the mold. This process is capable of making replicas with 10 nanometer resolution.

Nanoimprint lithography can produce the same pattern as electron beam lithography at significantly less cost and requires less skill. This is achieved by delegating the task of fabricating the mold using electron beam lithography to professionals. A nanoimprint mold can be purchased from a company or from UHNF. Alternatively, a researcher at UHNF can use our core technology to fabricate their own nanoimprint mold.