Lab Management

Lab management technologies reduce the cost of operation while improving the overall productivity of research infrastructure. This frees up staff time which is directed towards projects that best utilize and further develop their skills such as research, core technology development and services. The lab management technologies at UHNF have been developed, tested and refined since 2009. The most impactful ones are shared here in an effort to help improve the operation of research infrastructure around the world.

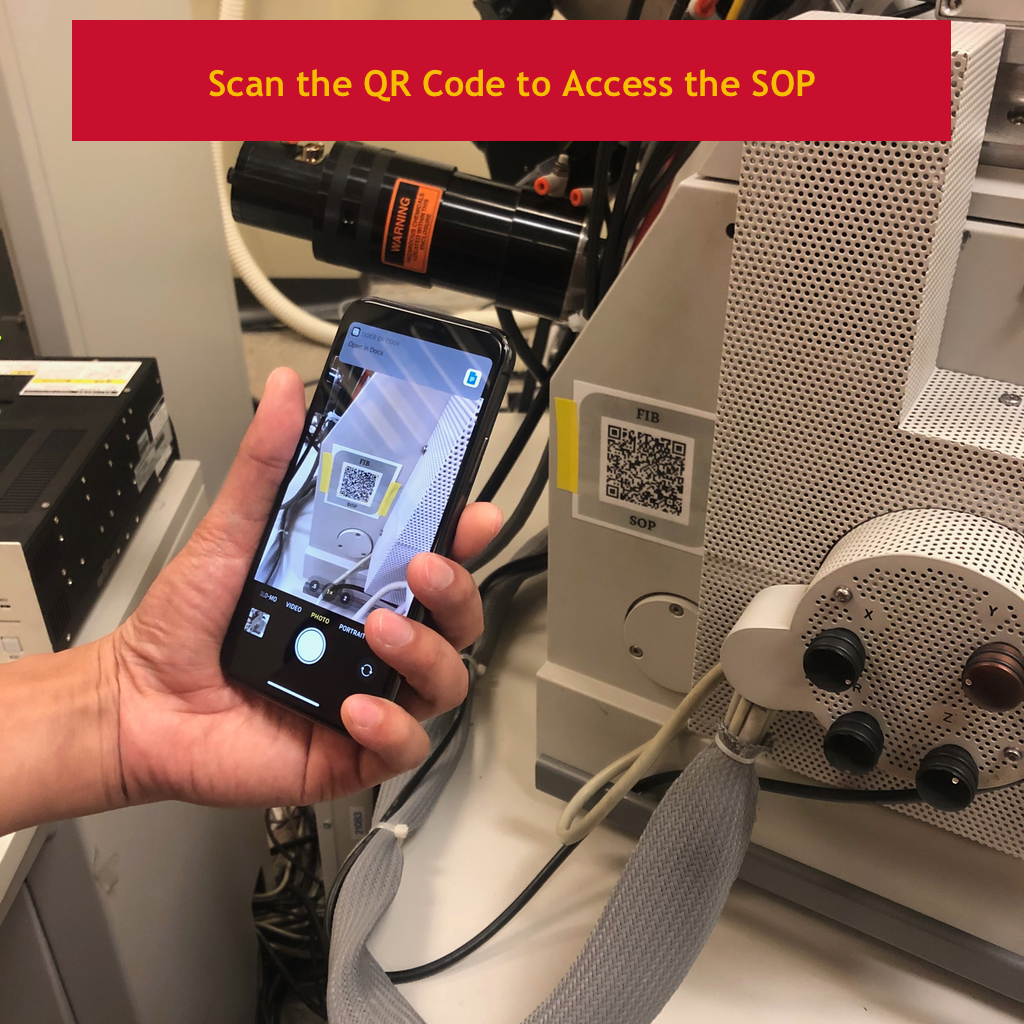

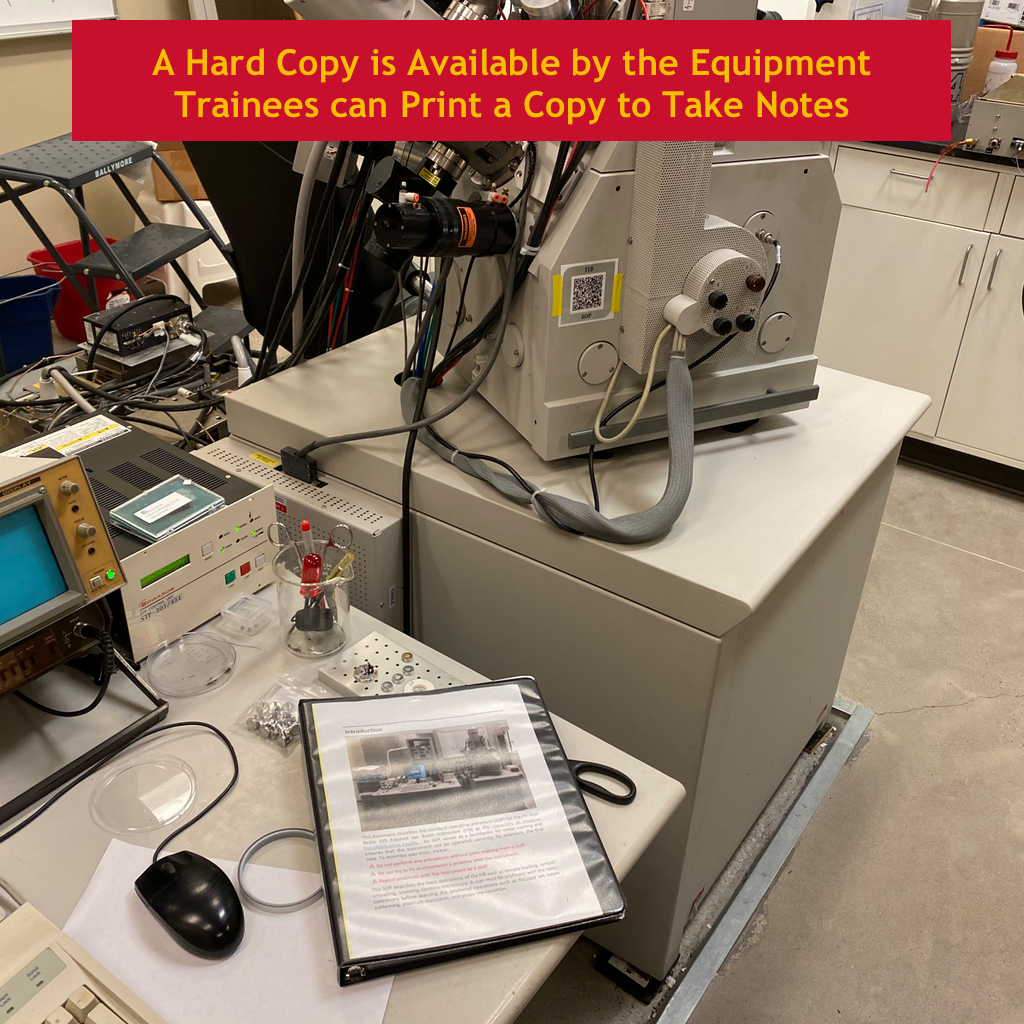

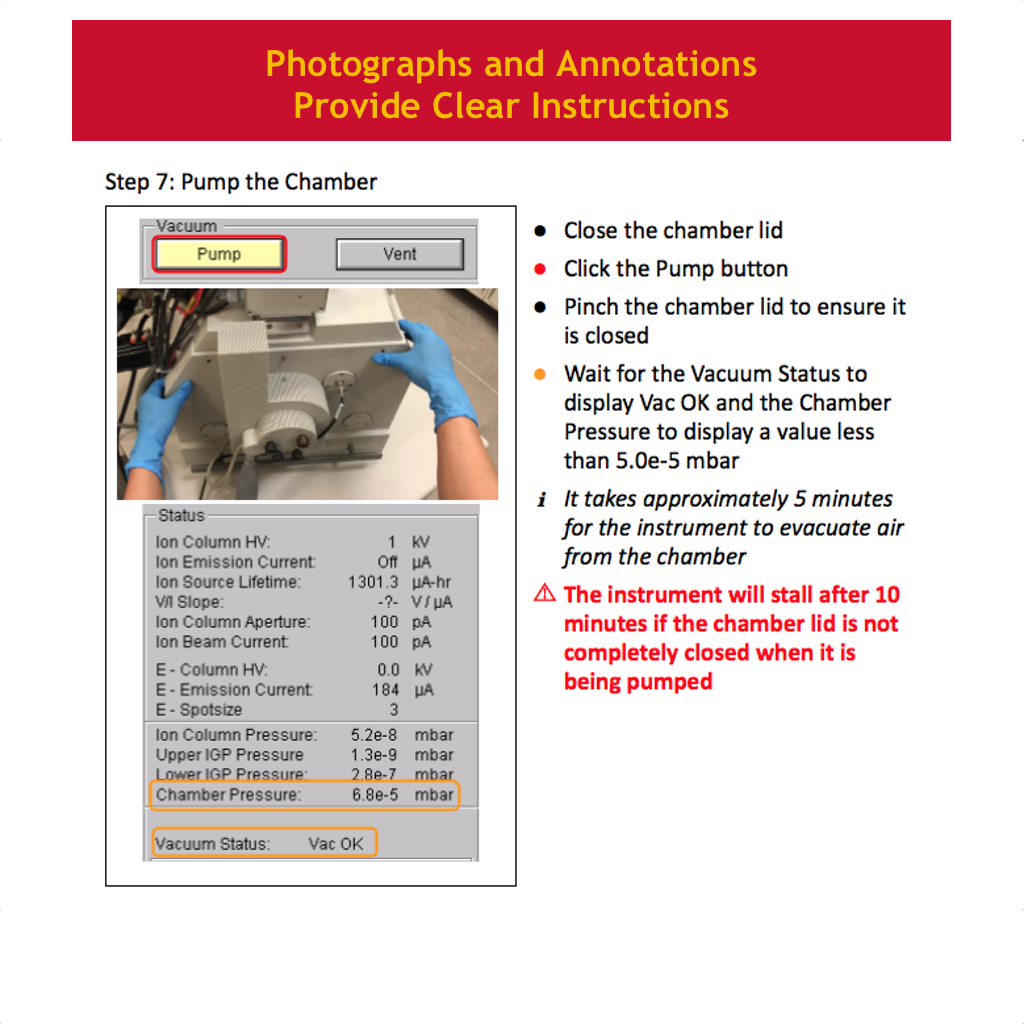

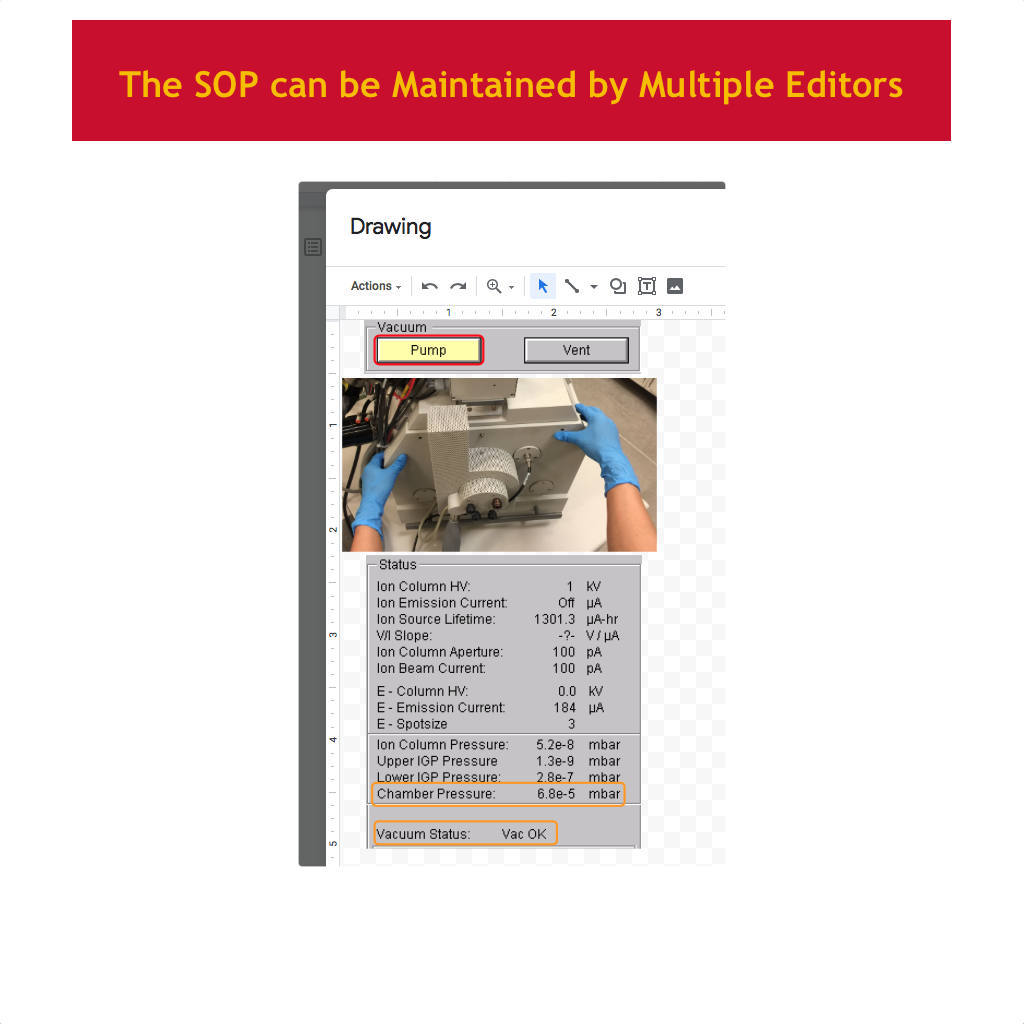

Standard Operating Procedure

A standard operating procedure (SOP) is a document that serves as a foundation for initial training and ensures that the instrument can be operated correctly, by everyone, the first time, and every time. UHNF SOP is written by staff who have mastered the operation of the equipment and assumes that the operator has no technical knowledge, skill or training. An operator with no prior experience who was trained once and waits a year before using it a second time has a good chance to successfully operate the equipment when they follow the SOP.

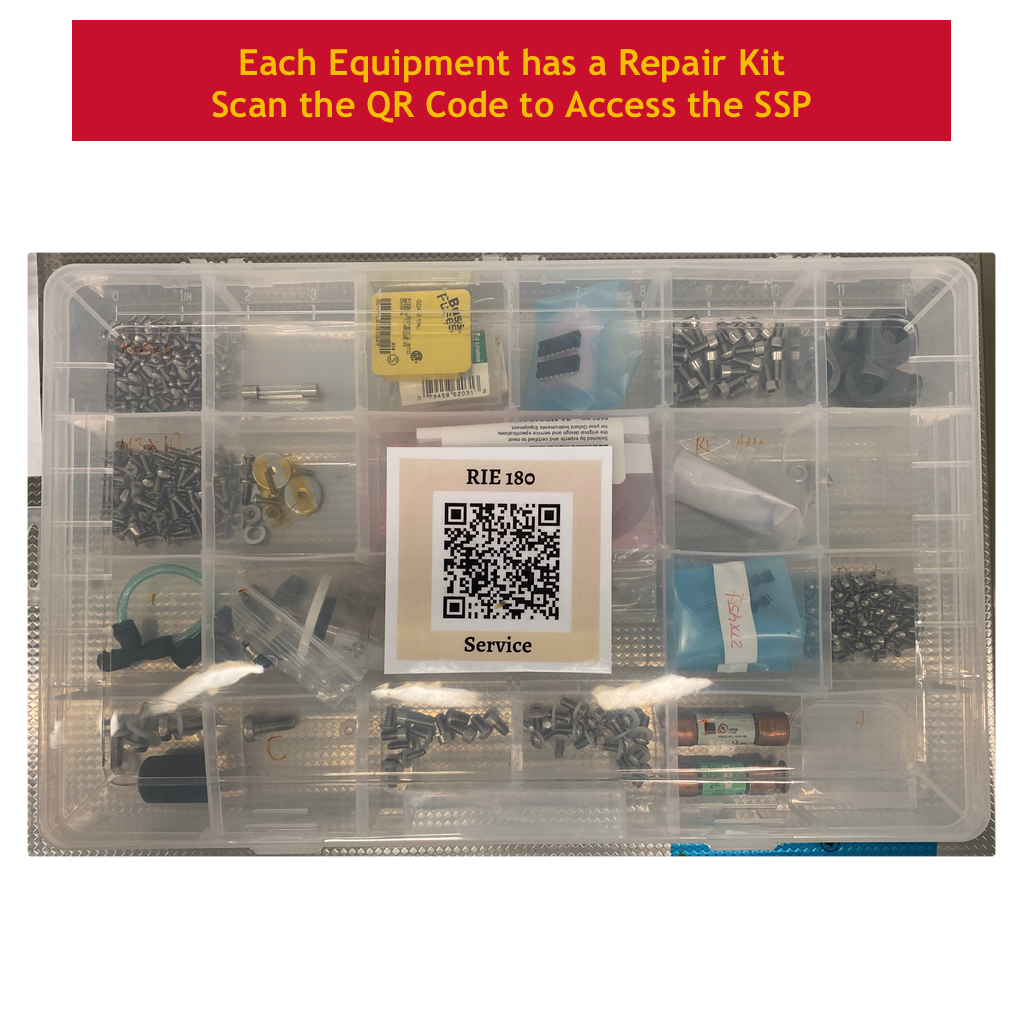

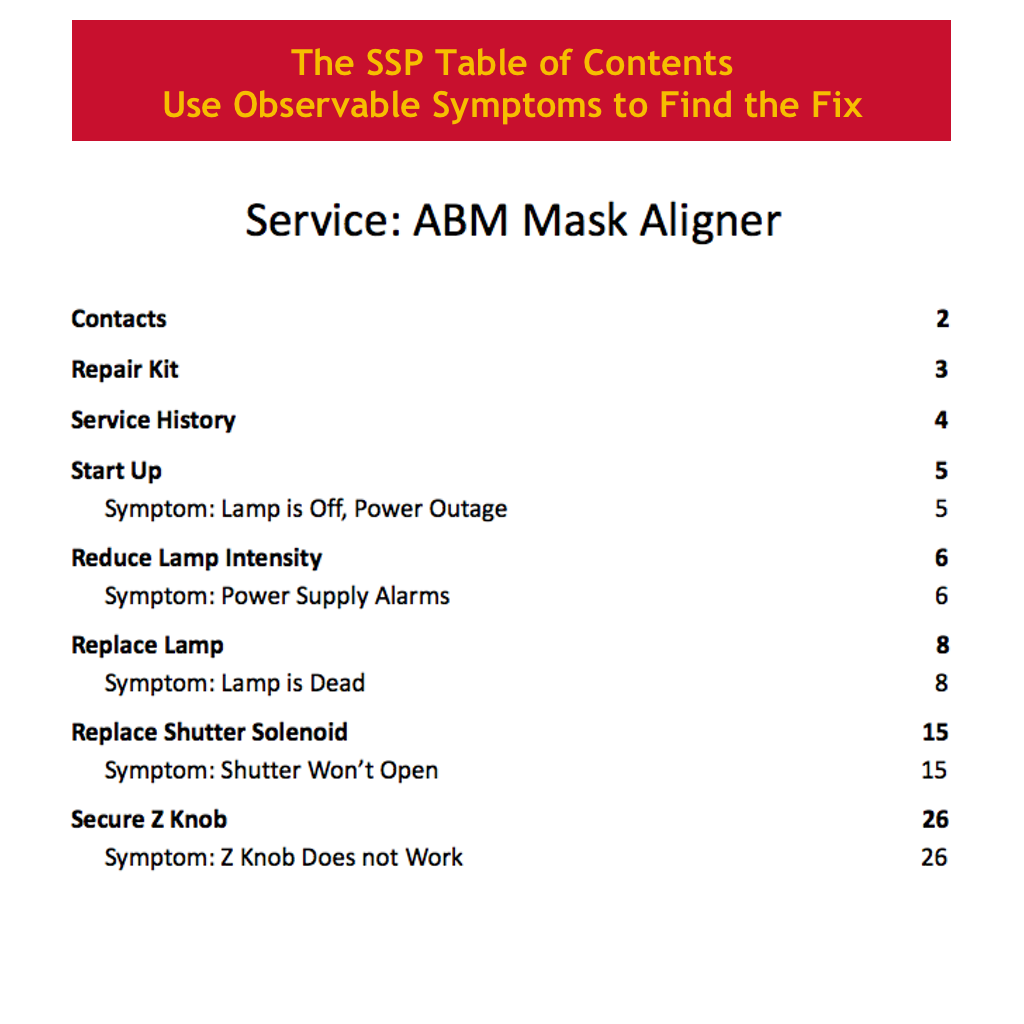

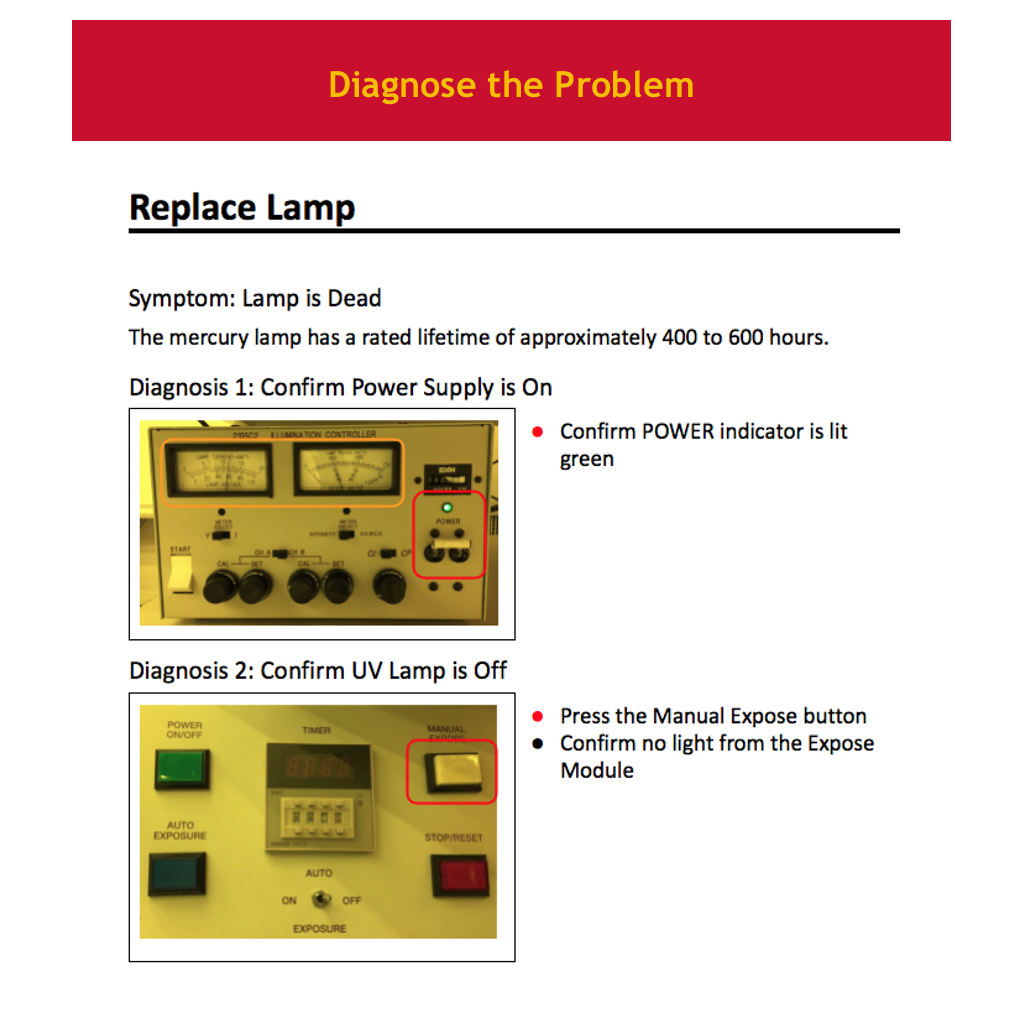

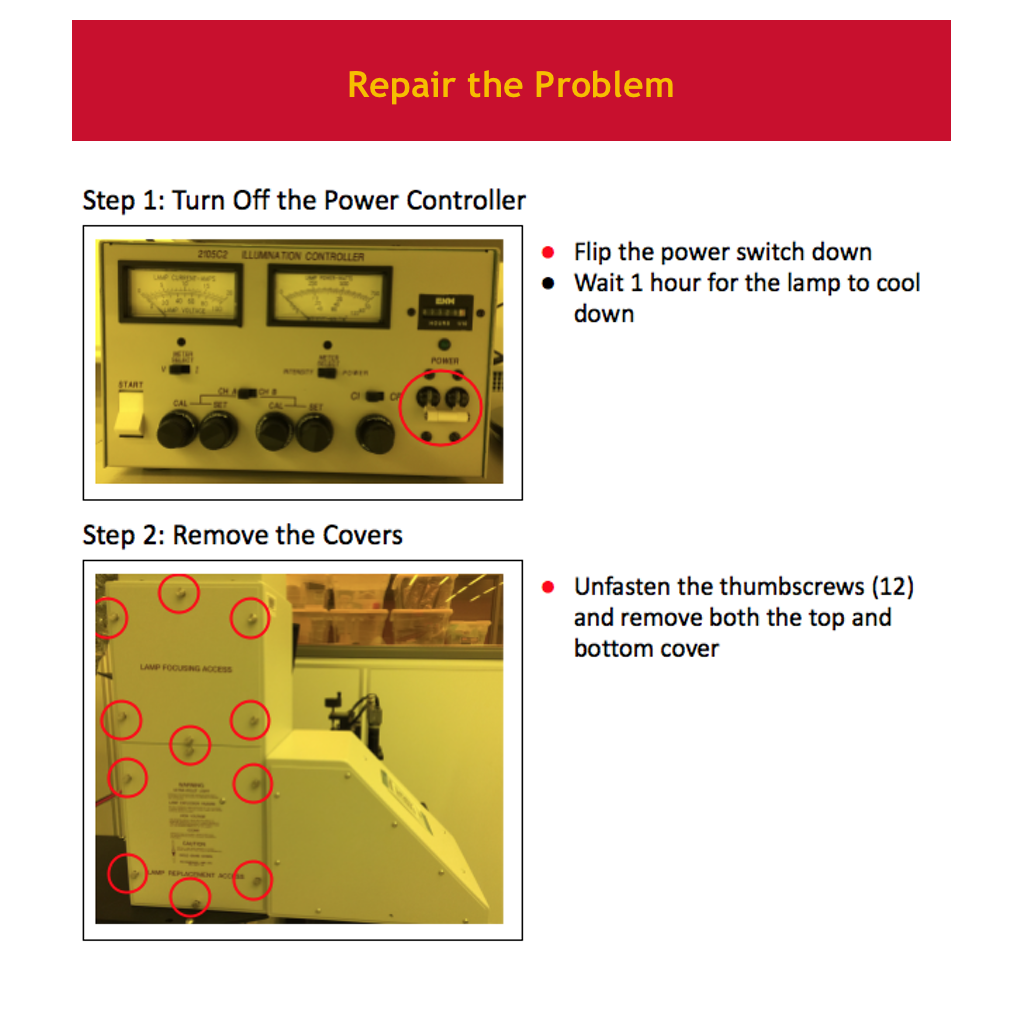

Standard Service Procedure

A standard service procedure (SSP) is a document that serves as a foundation for initial training and ensures that an equipment can be serviced correctly, by every staff, the first time, and every time. Every equipment service performed is meticulously recorded providing a history of communication, action and resolution. Once the repair is complete, the records are reviewed to draft an SSP procedure which includes observable symptoms, diagnostic procedures, and repair procedures. UHNF SSP enables staff to cover each other while maintaining high equipment up-time. The process of writing an SSP procedure also provide staff an opportunity to reflect on the job and communicate a better approach to solve the problem.

Maintenance Management System

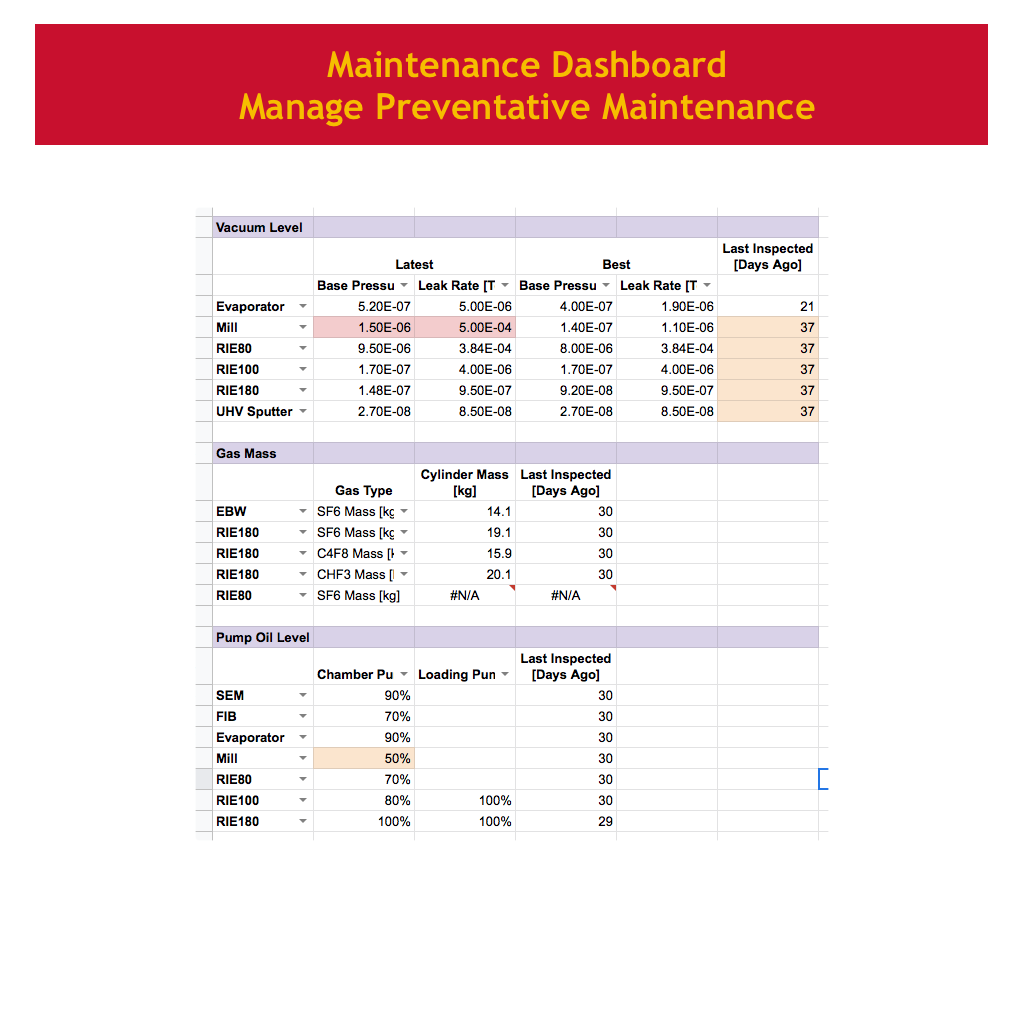

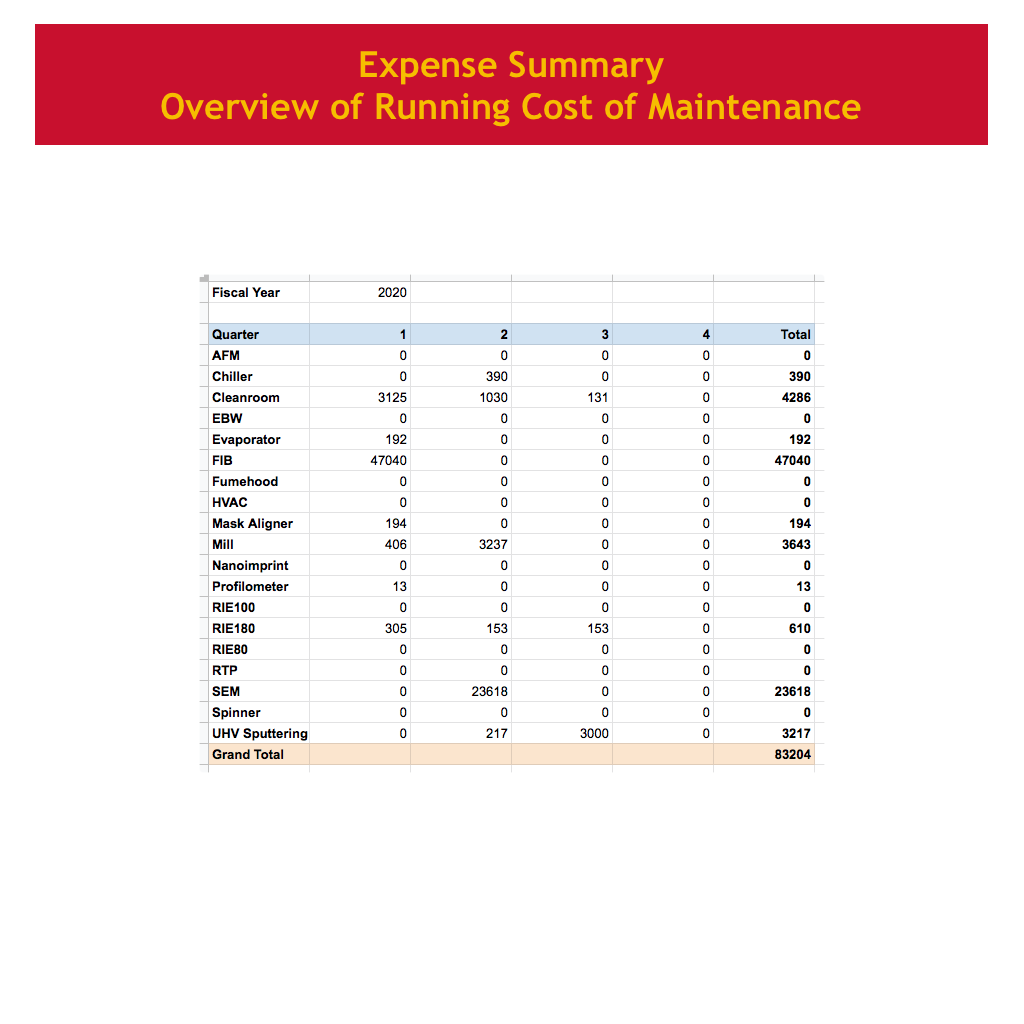

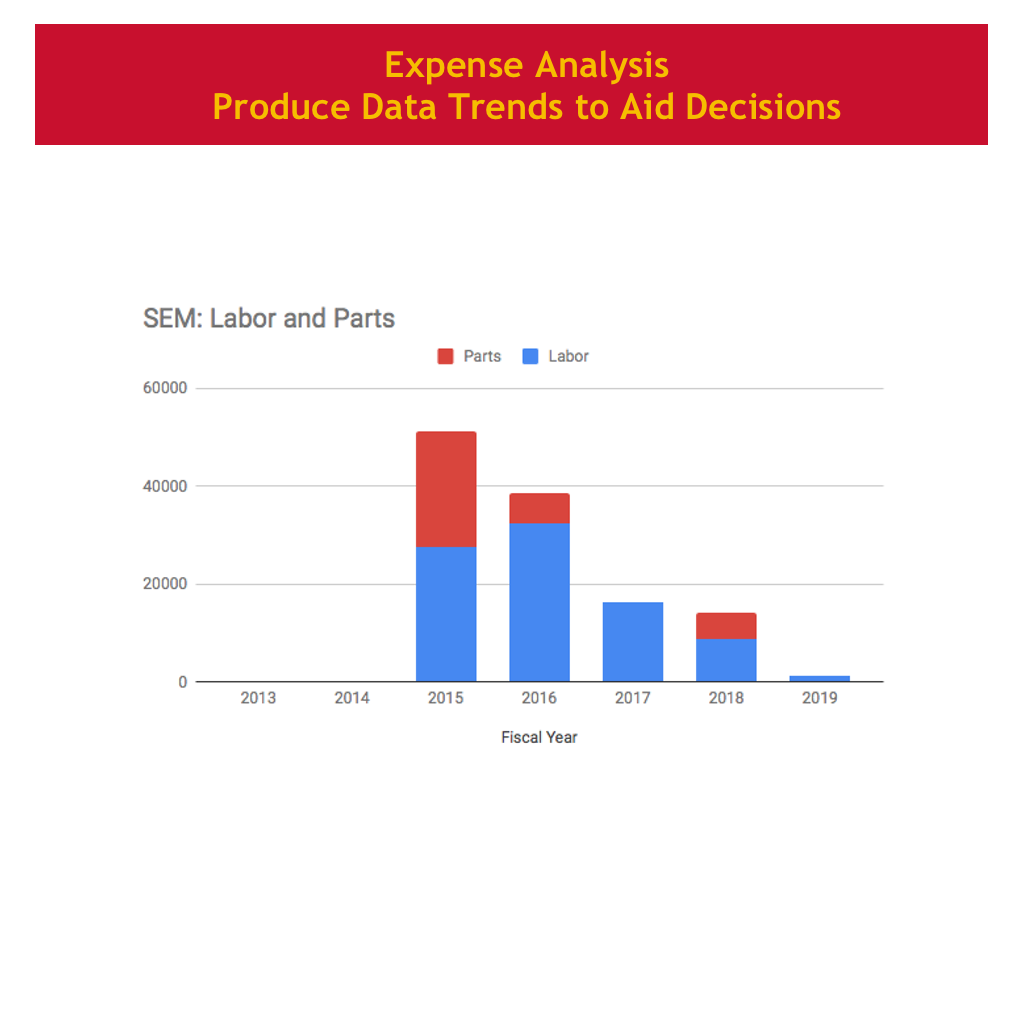

Proper maintenance ensures a lower cost of ownership and a higher equipment uptime. Our approach to maintenance has evolved over time as we learn more about each equipment, their components and various constituents to equipment failure. These experiences have lead to the development of an interactive online spreadsheet that records service data, provides actionable health indicators, and tracks the cost of maintenance.

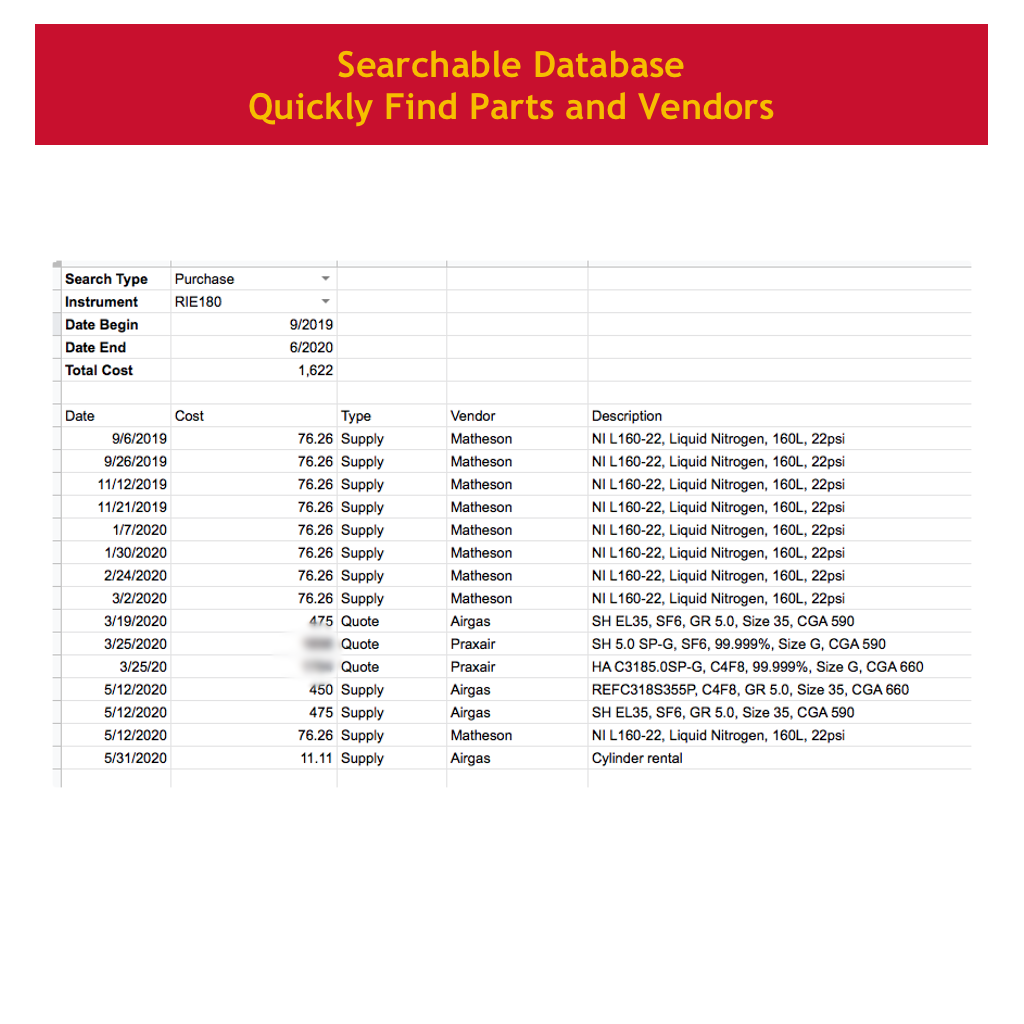

Maintenance staff provides service data such as equipment health indicators (vacuum level, oil level, etc), time spent repairing and parts purchased. The data is used to automatically update a dashboard that summarizes expenses and provide maintenance reminders. Purchasing parts is greatly facilitated by searching the history of all purchases.

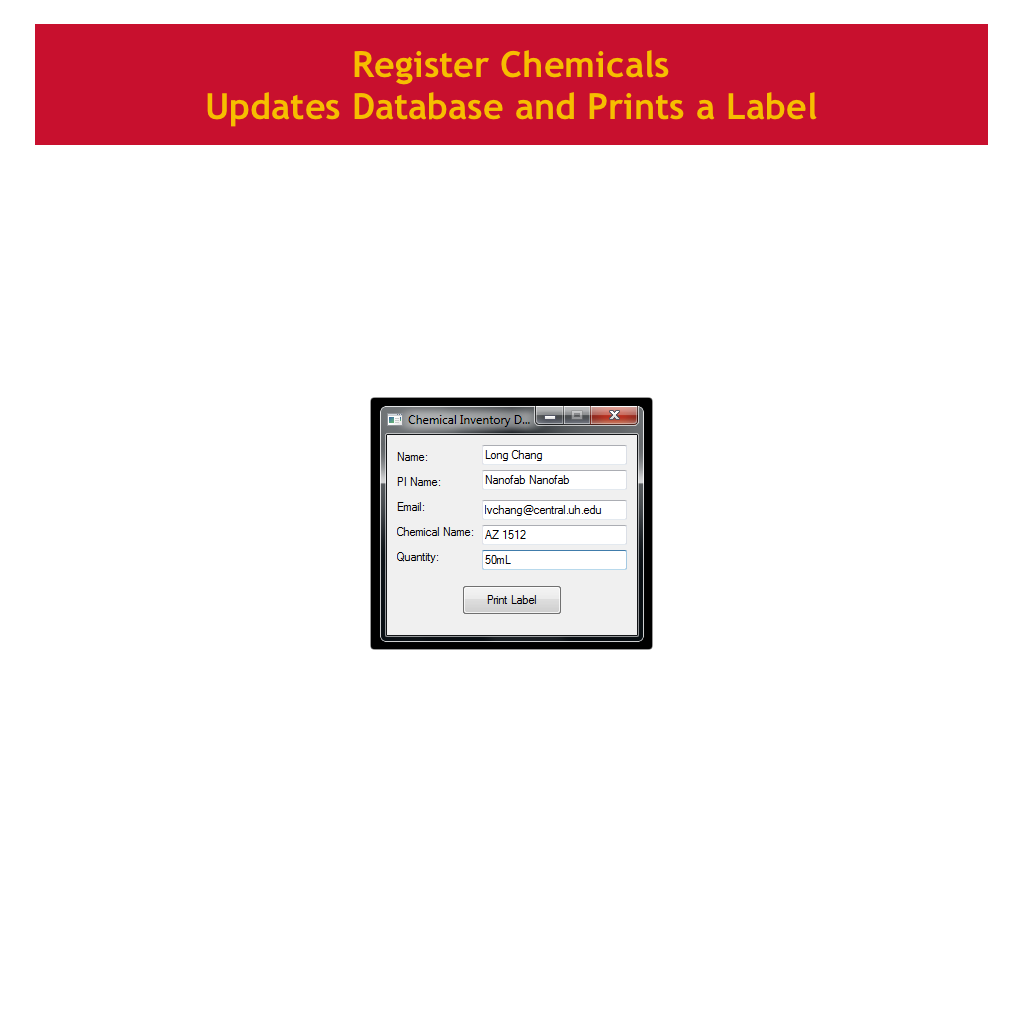

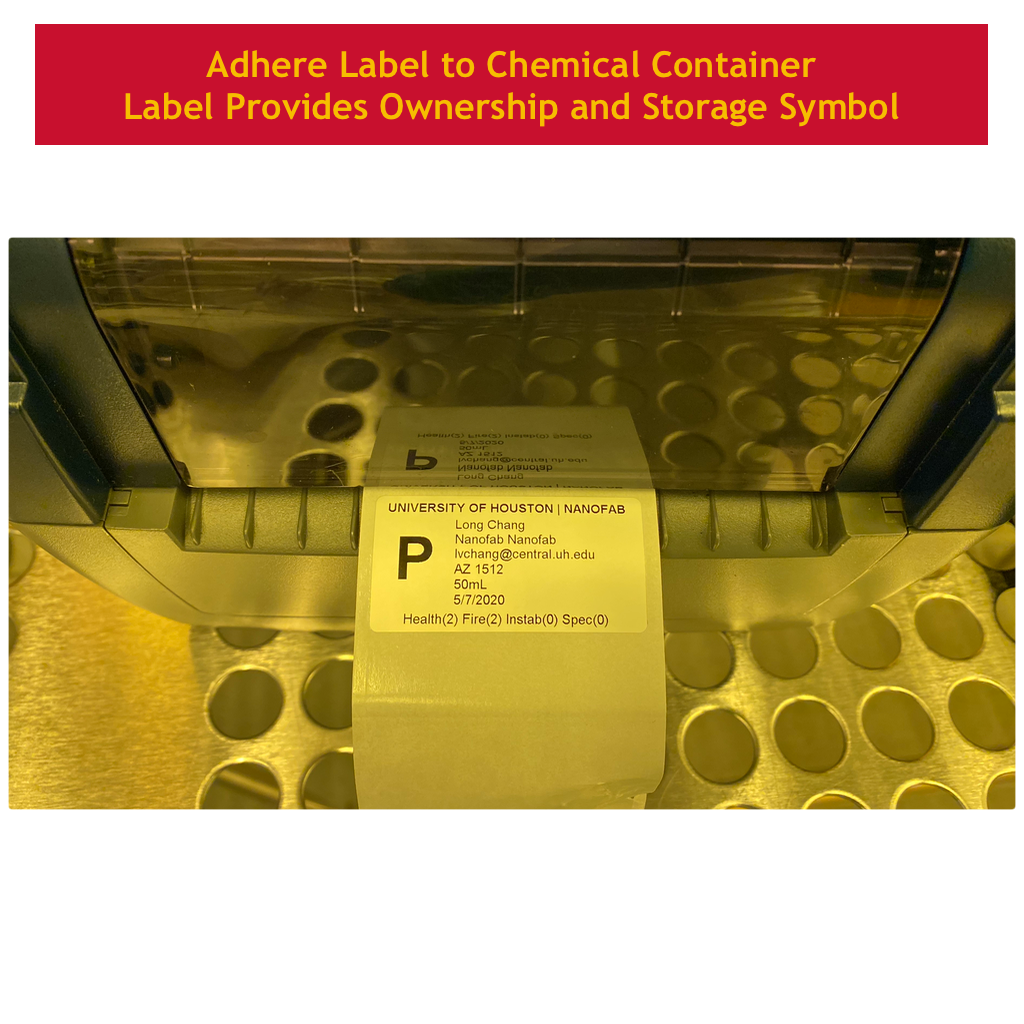

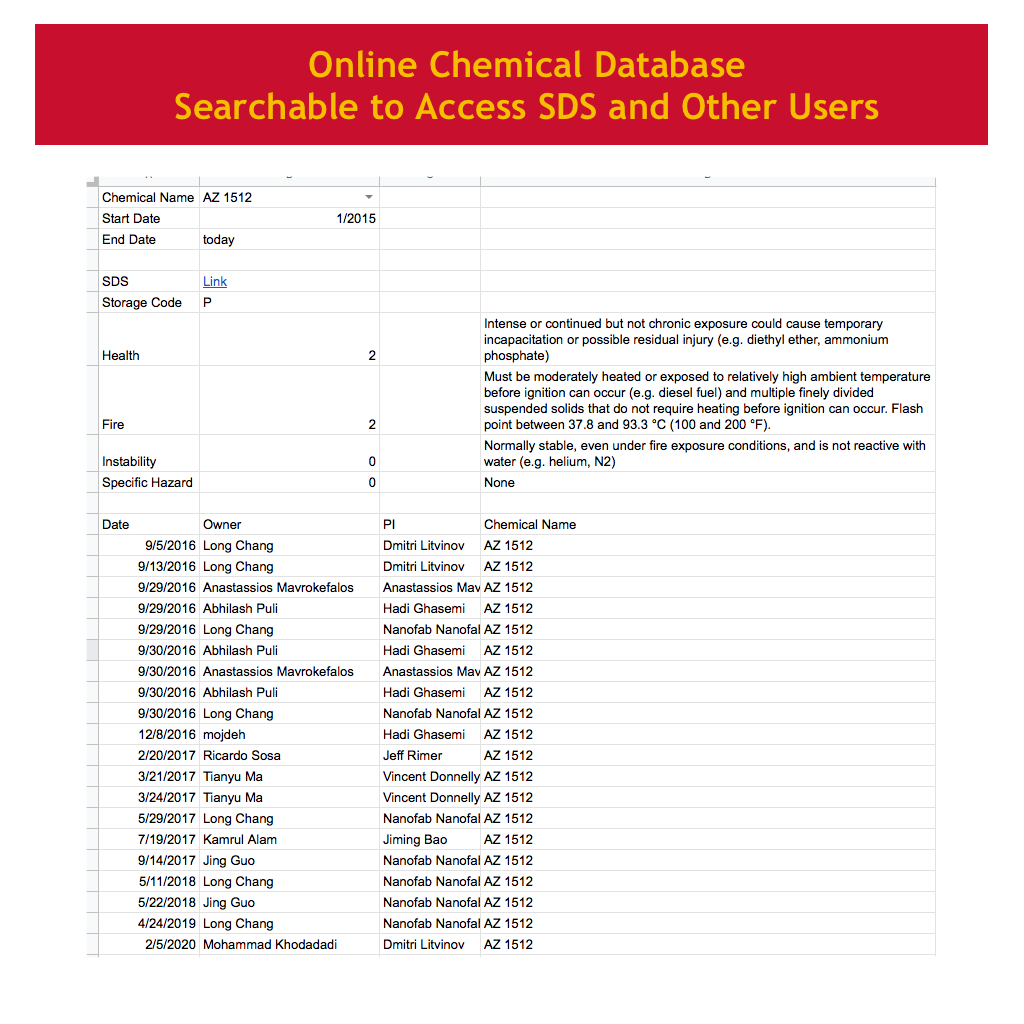

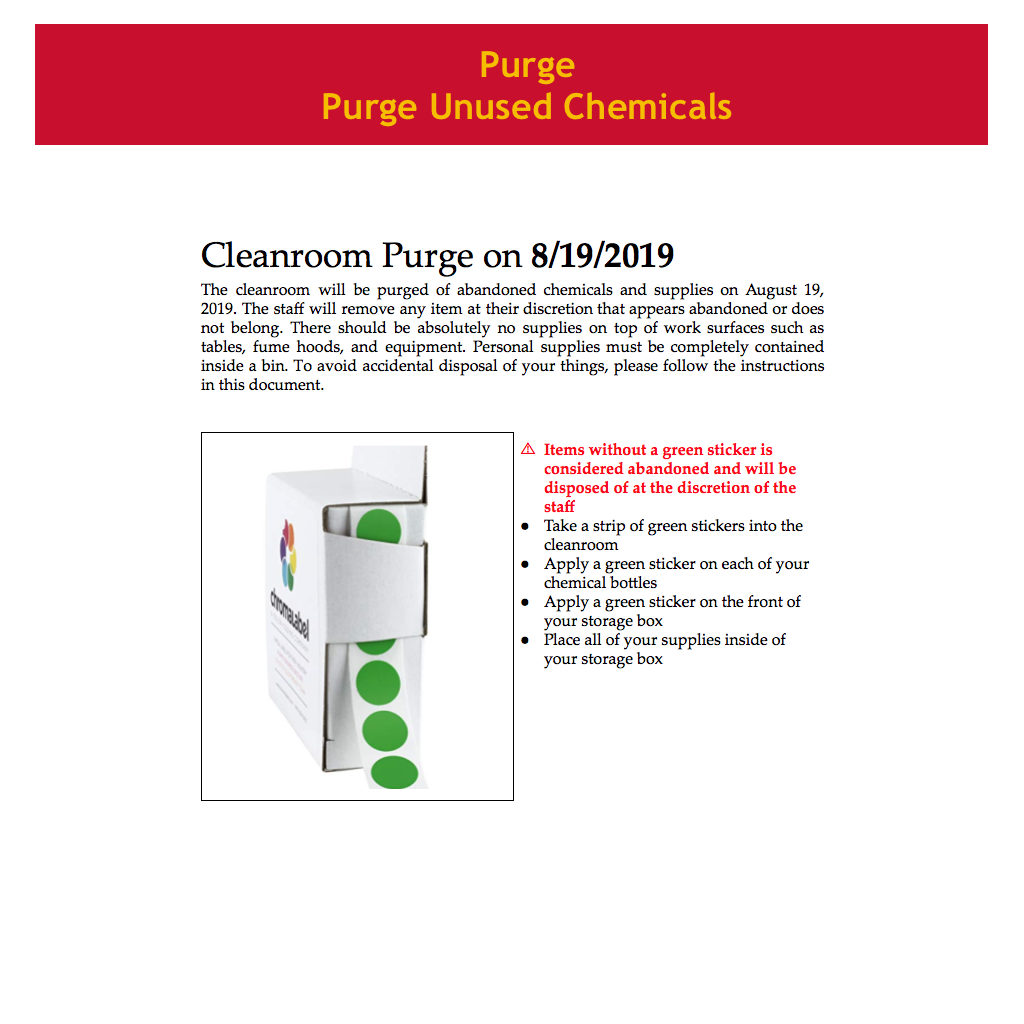

Chemical Inventory Management

An academic research infrastructure provide common chemicals and safely manage small quantities of special chemicals demanded by researchers. When a researcher brings their own chemicals into the lab, it must be registered to receive a label. The label is fixed on the chemical container and provides information on the owner, storage cabinet and basic hazard indicators. This registration also adds the item to an online chemical database that is accessible by all researchers. The chemical database provide quick access to the material safety data sheet, basic hazard information and a list of all researchers and faculty who have registered the chemical. Researchers who bring a new chemical must inform the staff and provide a material safety data sheet for review. Upon approval, the new chemical is added to the chemical database. The chemical inventory is purged once a year to ensure sufficient storage space. Purging is facilitated by safely disposing all chemicals without registration labels or a purge protection label.

Invoice Management

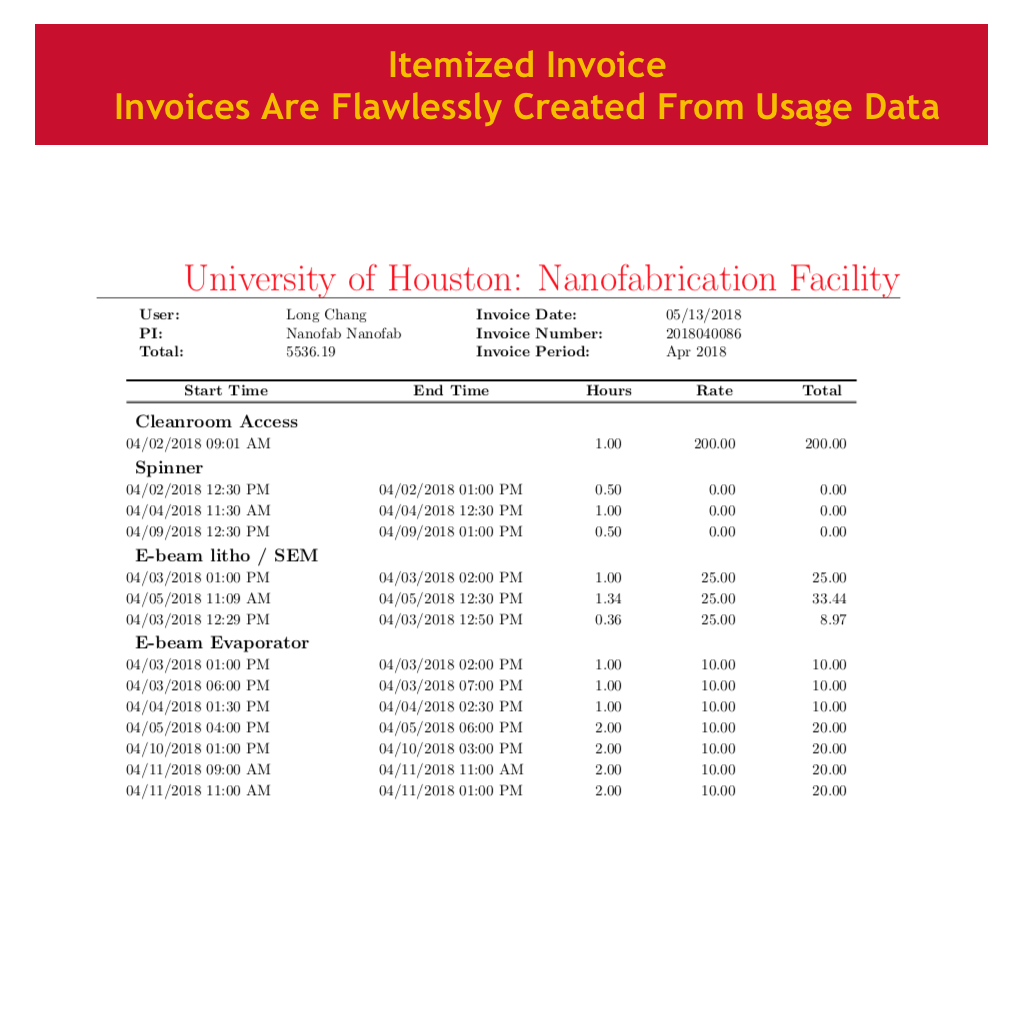

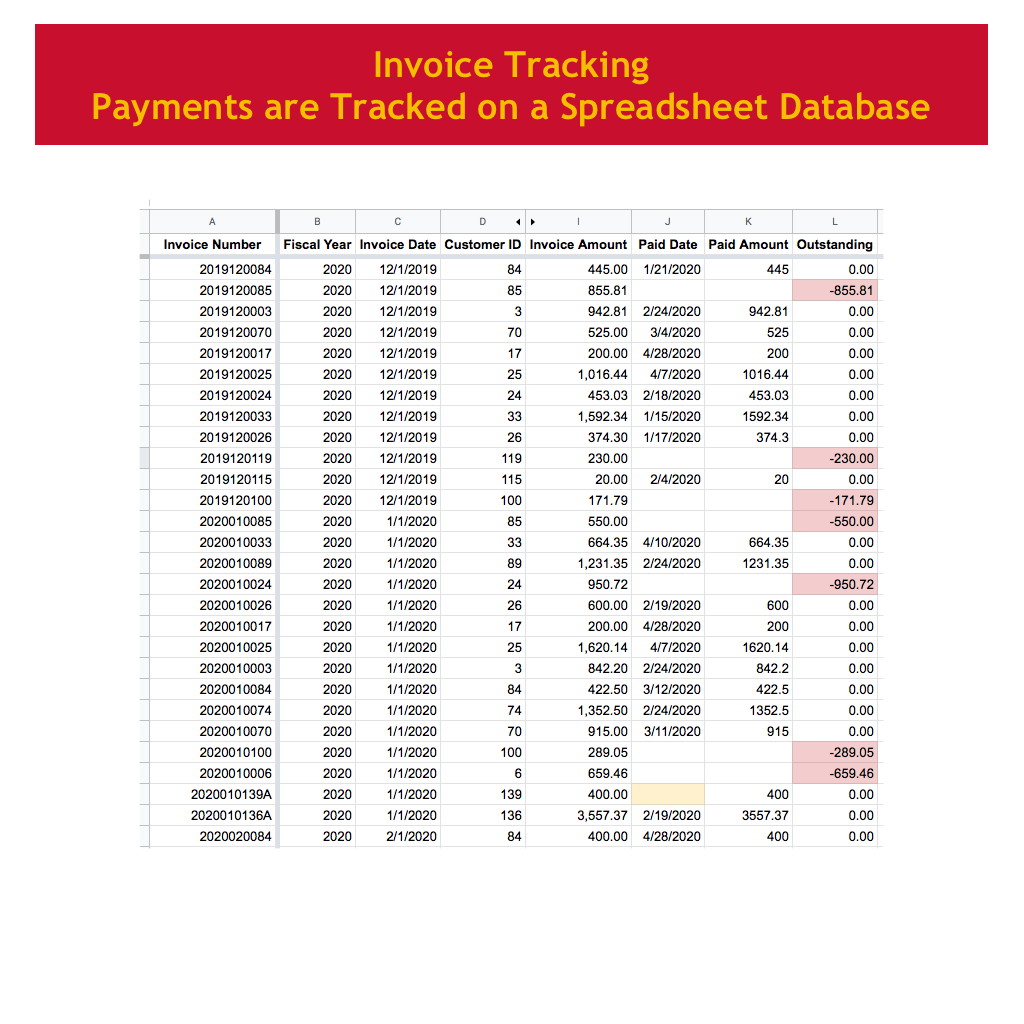

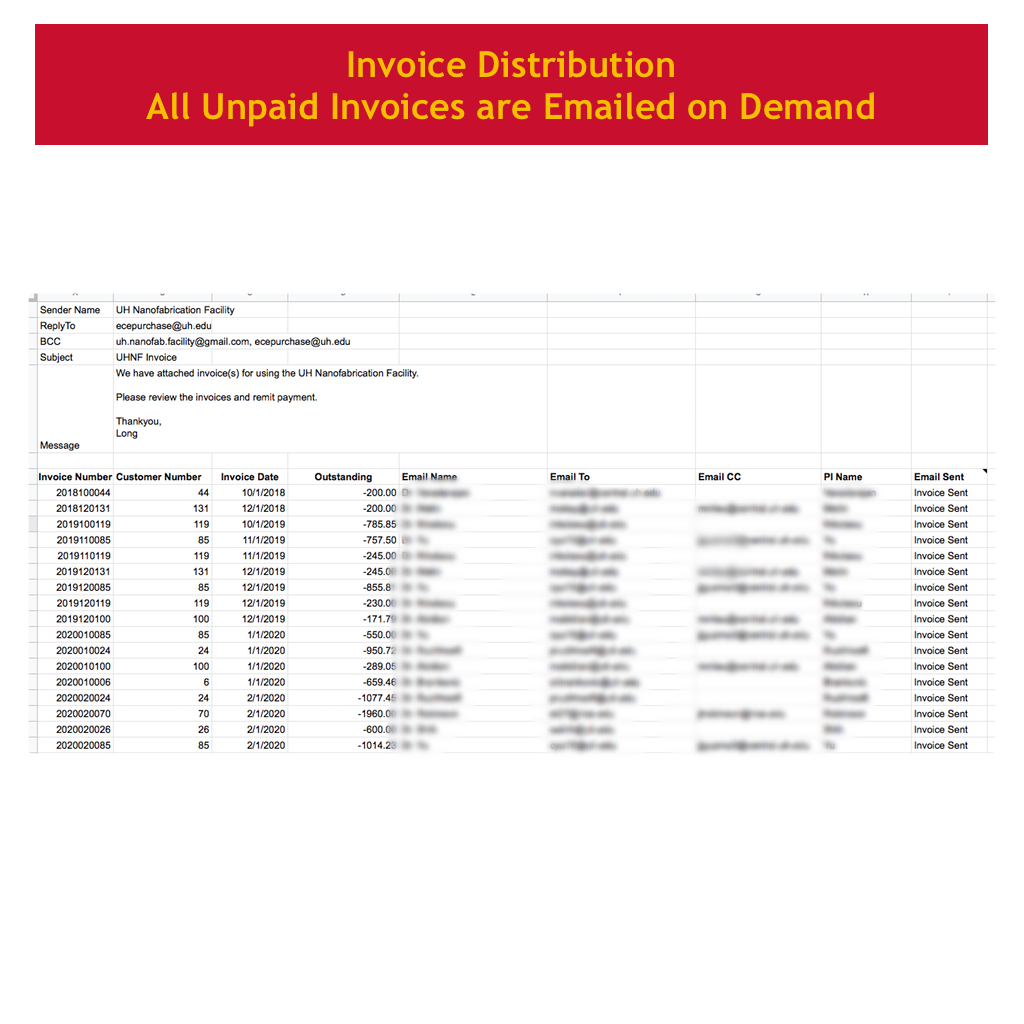

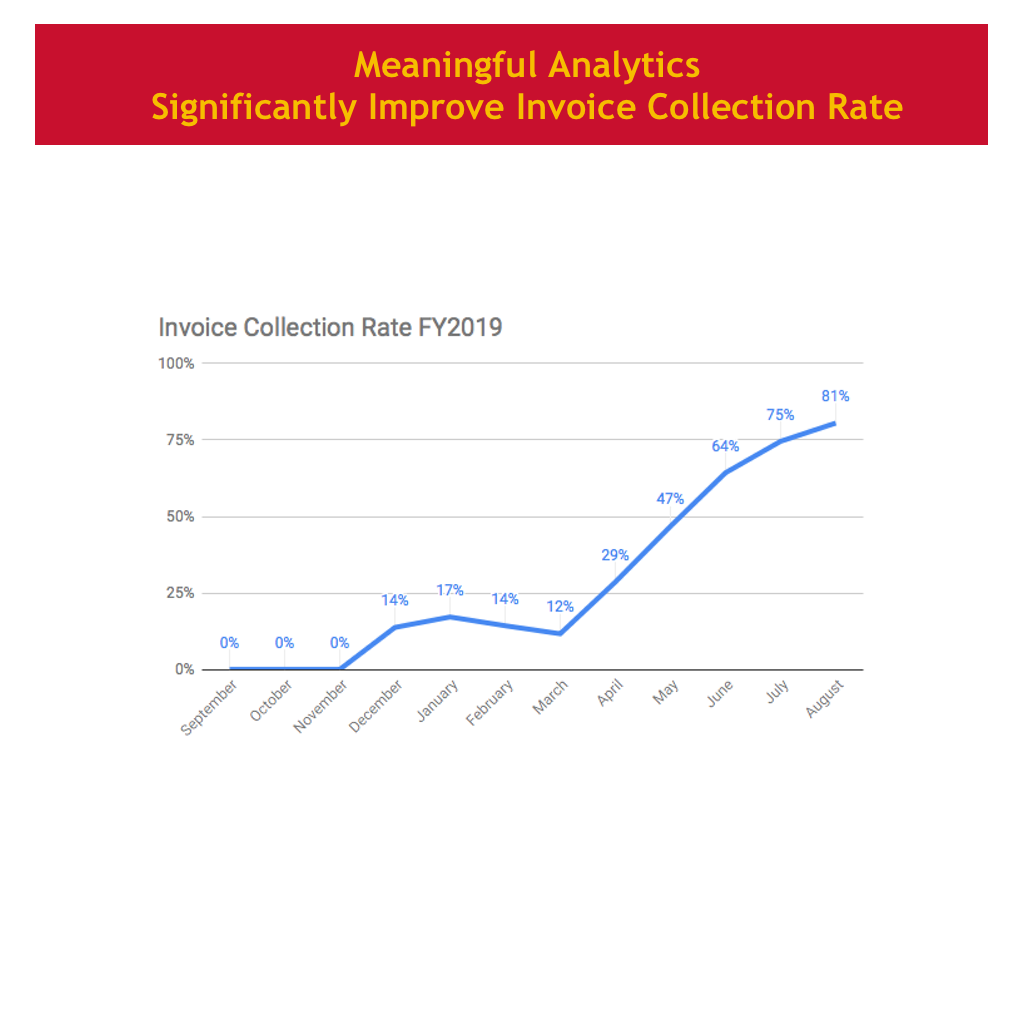

Custom software was developed to produce itemized invoices each month by analyzing facility access logs, equipment reservation logs, and equipment usage logs. New and past due invoices are tracked in a private online database. Payment data is used to update the database once a month. Then, all unpaid invoices are distributed by email. The invoice collection rate is monitored to determine if additional effort or interventions is necessary.

The invoice management system was launched on March 2019 in an attempt to resolve abysmal collection rates. The system gradually improved collection rates month after month until stabilizing at approximately 80%. This system is very efficient and takes only a few hours of labor each month.