Standard Servicing Procedure

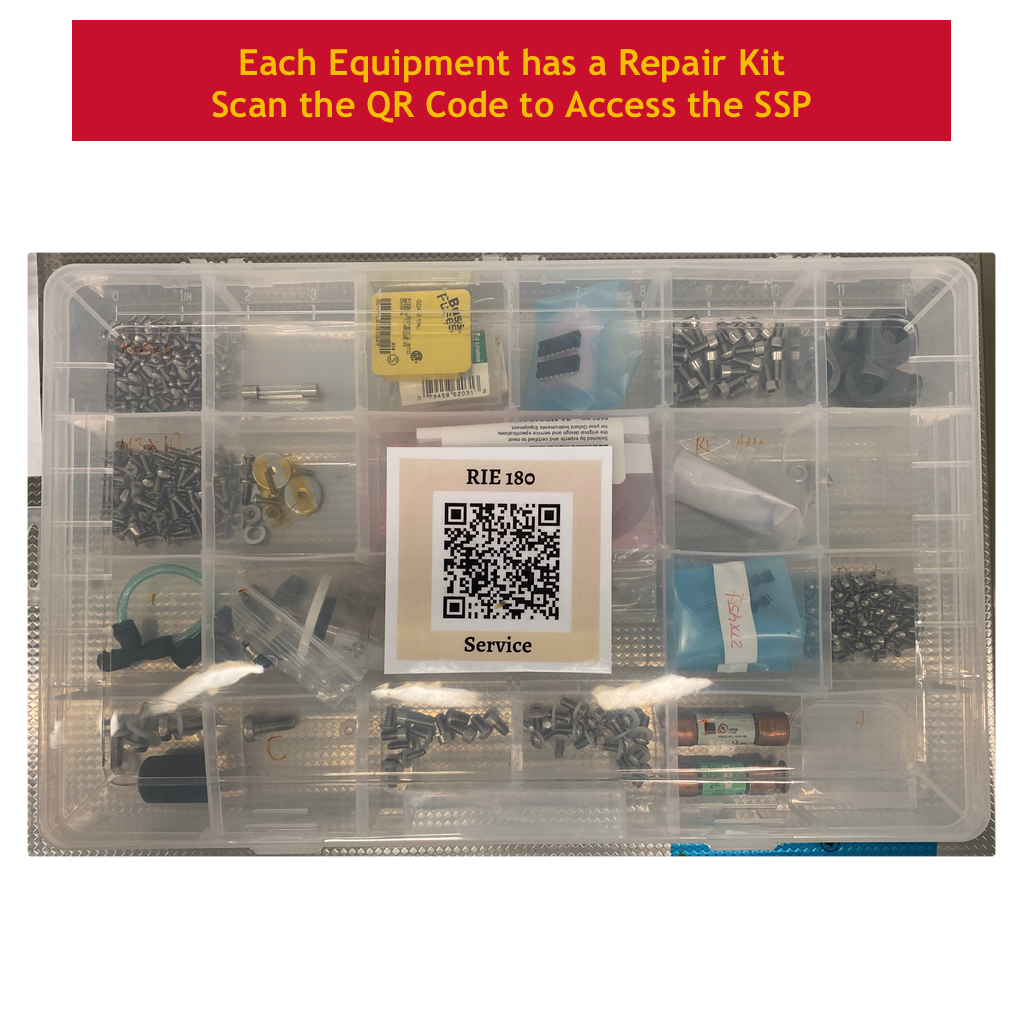

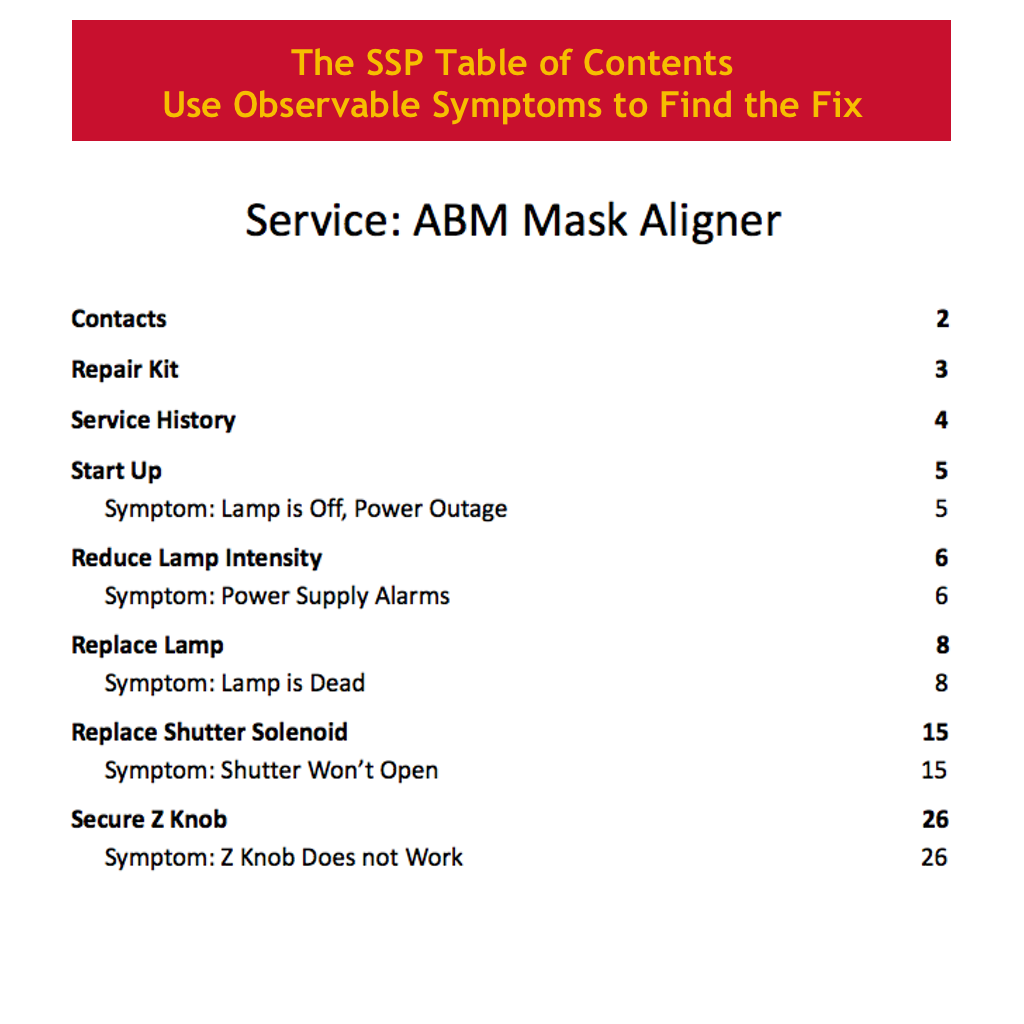

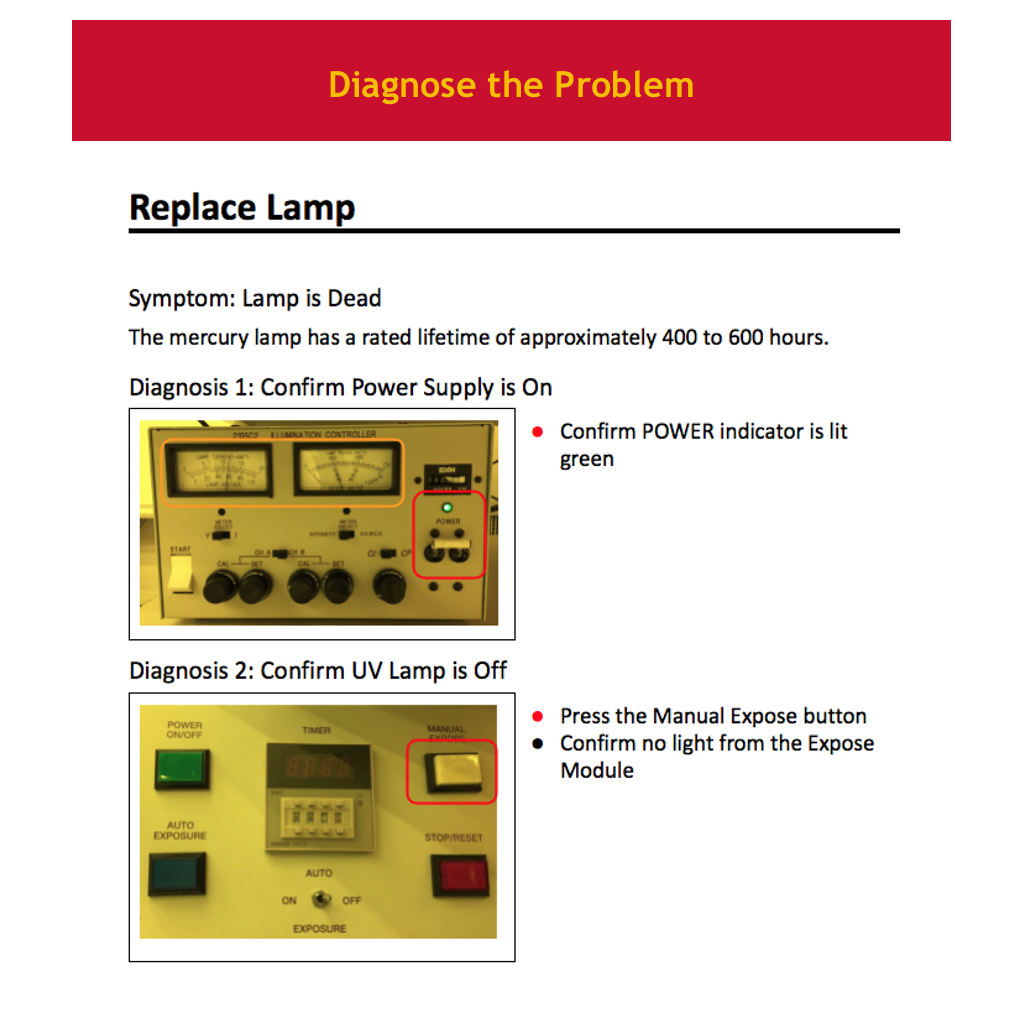

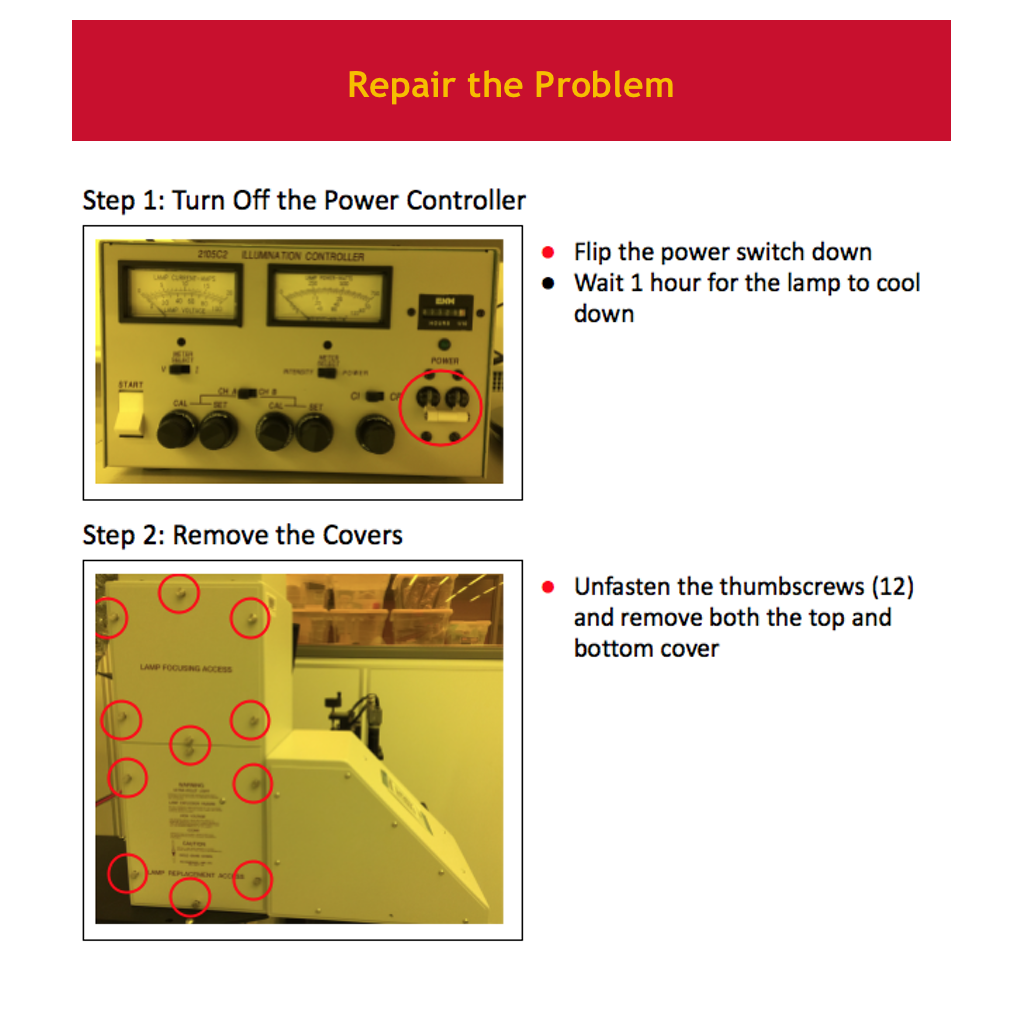

A standard servicing procedure (SOP) is a document that serves as a foundation for initial training and ensures that an equipment can be serviced correctly, by anyone, the first time, and every time. The SSP is written by an experienced equipment custodian and instructions are communicated via photographs, annotations and text. An equipment custodian can access the SSP by scanning a QR code located on the equipment toolbox.

UHNF Standard Servicing Procedure (SSP)

Without training or experience we were able to maintain and repair the majority of our equipment since 2009 with technical support from the manufacturer. This lead to the development of an advanced documentation technology that can deliver clear instructions for servicing scientific equipment. The implementation of this technology has significantly reduced equipment downtime and allows staff to cover each other. This also significantly reduces the learning curve for new staff and help develop good servicing practices.

Our library of SSP is available in the Core Technology section below. These documents are private to avoid misuse. Please contact us if you would like to gain access to the SSP.

We have developed a guide for the preparation of a standard servicing procedure. Make a copy of the guide to use it as a template for your own SSP.

Video Introductions

Core Technology

| Equipment SSP | Type | Technology |

|---|---|---|

| Jeol JBX-5500FS | Lithography | Electron Beam Lithography |

| ABM Mask Aligner | Lithography | Photolithography |

| Nanonex NX-2004 | Lithography | Nanoimprint Lithography |

| Asylum Research MFP-3D Origin+ | Microscopy | Atomic Force Microscopy |

| FEI DB235 | Microscopy | Focused Ion Beam |

| FEI XL-30 | Microscopy | Scanning Electron Microscopy |

| Tencor Alpha-Step 200 | Microscopy | Profilometry |

| Oxford Instrument RIE 180 | Etching | Reactive Ion Etching |

| Oxford Instrument RIE 100 | Etching | Reactive Ion Etching |

| Oxford Instrument RIE 80 | Etching | Reactive Ion Etching |

| KRI KDC75 | Etching | Ion Milling |

| AJA ATC-2200 | Deposition | Sputtering |

| Denton Desk II | Deposition | Sputter Coating |

| Custom Thermionics Ebeam Evaporator | Deposition | Electron Beam Evaporation |

| Accuthermo AW410 | Others | Rapid Thermal Processor |