PMMA and HSQ bilayer is a useful combination. HSQ is a negative tone resist with almost negligible etch rate in an oxygen plasma. On the contrary, PMMA etches very quickly in an oxygen plasma. In addition, the process pressure can be adjusted to control the etch to achieve vertical sidewalls or undercut. Since this is a dry process, smaller structures with higher aspect ratios can be achieved. The pattern can also be easily reversed using electron beam deposition and lift-off.

Objective

Determine the vertical and lateral etch rate of PMMA in an oxygen plasma.

Design of Experiment

- Begin with a 3″ Silicon substrate

- Si, 3″, <100>, P/B, 10-20 Ohm-cm, SSP, 500nm Thermal Oxide

- Spin on 107 [nm] of PMMA 950K

- Dispense PMMA950 C2 across entire wafer

- Spin at 2500 [rpm] at 1250 [rpm/s] for 60 [s]

- Bake on a hotplate at 180 [ºC] for 120 [s]

- Spin on 73 [nm] of HSQ

- Dispense Dow Corning XR-1541 4% (HSQ) across the entire wafer

- Spin at 2500 [rpm] at 1250 [rpm/s] for 60 [s]

- Bake on a hotplate at 90 [ºC] for 120 [s]

- Expose grating patterns using electron beam lithography

- Grating patterns are 100, 200, 400, and 1000 [nm] wide lines with 50% duty cycle

- Dose is 700 [μC/cm2]

- Develop by immersing in 25% TMAH for 60 [s]

- Measure the height of each grating with an Atomic Force Microscope

- Etch the patterns in an reactive ion etcher

- Oxford DRIE 180

- RF Power at 70 [W]

- O2 at 70 [sccm]

- Pressure range from 3.3 to 40 [mTorr]

- DC bias was 250 [V]

- Temperature is 20 [C]

- Helium backpressure is 10 [Torr]

- Oxford DRIE 180

- Measure the vertical and lateral etch rate of PMMA in an oxygen plasma with a Focused Ion Beam

Results and Discussion

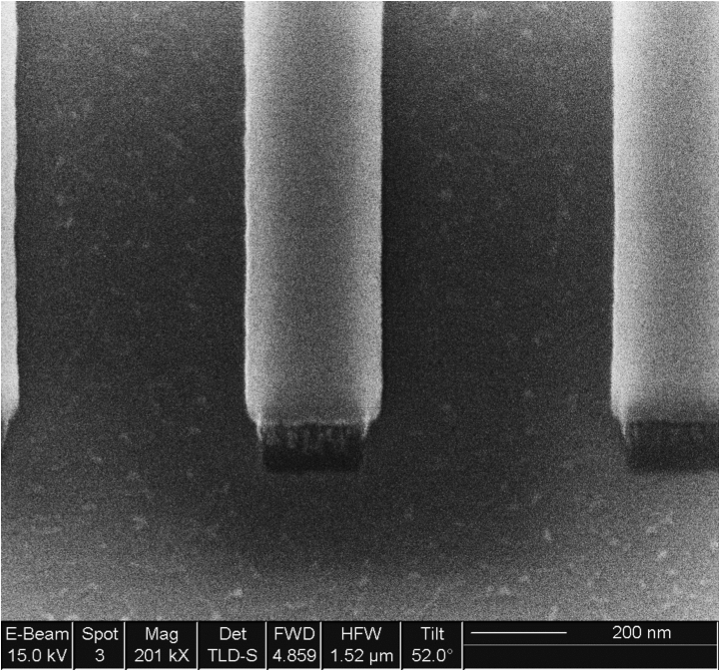

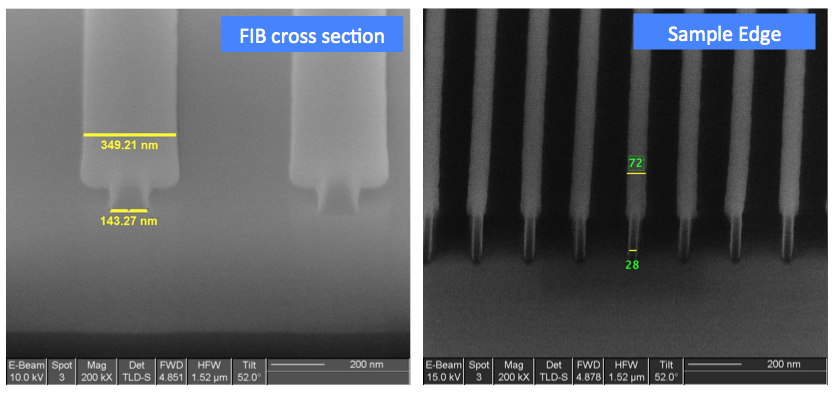

Figure 1 shows a FIB cross section of the 400 nm grating sample after it has been etched and the edge of a 100 nm grating sample. By measuring the width of the grating and the width of the undercut and knowing the etch time, we can calculate the undercut rate. All of our measurements are recorded using the cross-section method, but it is questionable whether the extra effort produces more accurate results.

Figure 2 show the vertical etch rate, lateral etch rate and etch anisotropy (lateral / vertical) as a function of the process pressure. The vertical and lateral etch rate increases monotonically as pressure increases. The lateral etch rate does not appear to be influenced by the size of the gratings, so the average lateral etch rate is shown. The etch does not produce an angled sidewall, but instead produces a near vertical sidewall underneath the etch mask (HSQ) as shown in Figure 1. A combination of a lower pressure anisotropic etch followed by a higher pressure lateral etch can be used to control the amount of undercut for various PMMA film thickness.

Figure 2: With increasing pressure, the etch rates increases while the etch anisotropy decreases.

At the beginning of the process development, we used expired HSQ. Figure 3 shows an image of artifacts/defects that results from using expired HSQ. The shelf life of HSQ is specified to be 6 months. From our experience, the first sign of expired HSQ is the observation of HSQ residue speckled all over the sample after the sample has been exposed and developed. The shapes of these residue are then transferred into the PMMA during the reactive ion etch process. Since the etch is not perfectly anisotropic and the residue is small, the PMMA underneath the residue etches away leaving the residue on the sample surface. All measurements were made using samples with new HSQ.