Photolithography

Photolithography is a technique for replicating patterns with minimum features below 1 [μm]. This is achieved by shining ultraviolet light through an opaque mask with transparent patterns. The masks are designed by researchers and typically produced by manufacturers. The transmitted light activates a light sensitive media underneath which produces structural contrast when developed.

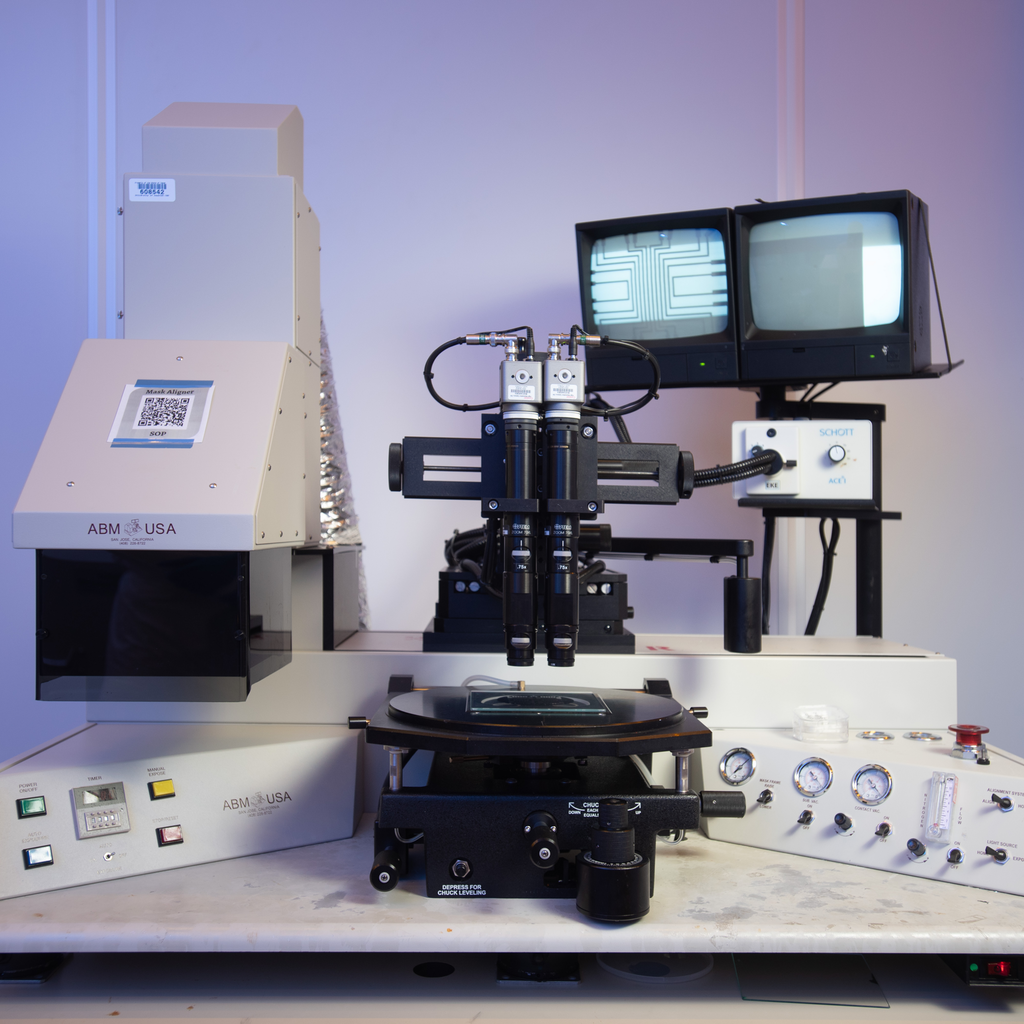

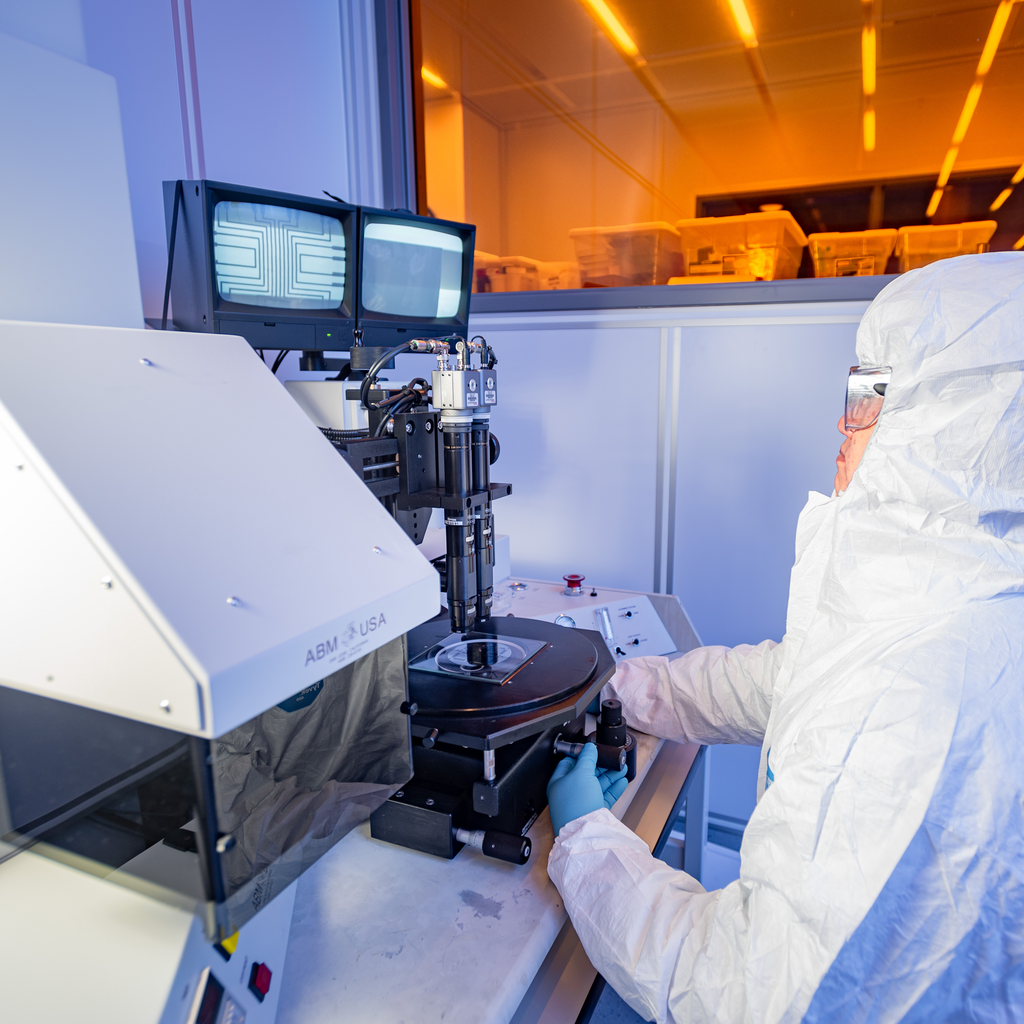

ABM Mask Aligner

| Description | Specification |

|---|---|

| Printing Modes | Mechanical Hard/Soft Contact Vacuum Hard/Soft Contact Proximity with Planarization |

| Resolution | 1000 [nm] or better |

| Sample | 100 [mm] wafer or 75 [mm] wafer or custom size |

| Mask Size | 5" x 5" |

| Wavelength | 365 [nm] and/or 400 [nm] |

| Expose Timer | 0.1 to 999.9 [s] |

| Alignment Magnification | 90x to 600x |

Examples

Core Technology

| Core Technology | Description |

|---|---|

| SOP: ABM Mask Aligner | This document is the standard operating procedure (SOP) for the ABM Mask Aligner at UHNF. This SOP serves as a foundation for initial training and ensures that the equipment can be operated correctly, by everyone, the first time. |

| SSP: ABM Mask Aligner | This is a service manual we created for the ABM Mask Aligner at UHNF. This document ensures that any staff can effectively perform routine service or repairs effectively, quickly and at significantly lower cost. This document is restricted to equipment custodians. Contact us for access. |

| AZ1512 | AZ1512 is a positive tone UV media with below 2 [um] resolution and a sensitivity of 50 [mJ]. AZ1512 costs <$1/mL and has an infinite shelf life. |

| Adhesion on Silicon | Photoresist does not adhere to hydrated silicon surface. Here we explore various approaches to improve photoresist adhesion. |

| Lor5A/AZ1512 | LOR5A/AZ1512 comprise of a layer of AZ1512 above a layer of LOR5A. After patterning, the LOR5A pattern will always be wider than the AZ1512 pattern. This undercut greatly facilitates the lift-off process. |

Guide

| Guide | Description |

|---|---|

| Exposure System | The exposure system of a mask aligner generates light and forms it into a large beam with uniform intensity, typically within 2% across a 6″ x 6″ square. The intensity of the light is calibrated and controlled to provide repeatable exposures. |

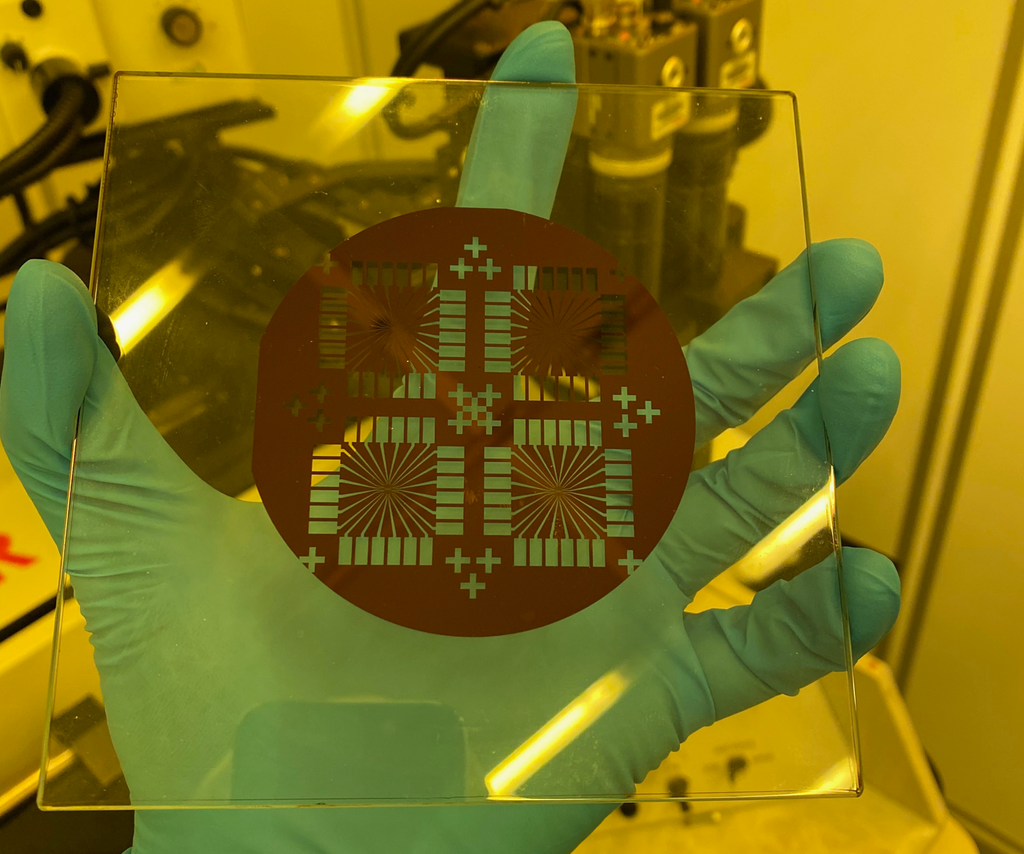

| Photomask | A photomask (or just mask) is a plate with dark (opaque) and clear (transparent) patterns. The clear regions of the mask allow light to pass through to expose a light sensitive film underneath. The patterns are drawn using KLayout and sent to a supplier to make the mask. |