Nanoimprint Lithography

Nanoimprint lithography is a technique for replicating patterns with minimum features below 10 [nm]. This is achieved by pressing a mold into a solid media and applying heat. The heat softens the media to the consistency of honey, enabling the media to flow and conform to the patterns in the mold. Once the media returns to room temperature, the media solidifies into a negative replica of the mold. An alternative technique uses a liquid media that gets cured into a solid after it has conformed to the mold.

Nanonex NX-2004

| Description | Specification |

|---|---|

| Printing Modes | Thermal Imprint UV Imprint Thermal + UV Imprint |

| Resolution | < 10 [nm] |

| Sample | 100 [mm] wafer or 75 [mm] wafer or custom size |

| UV Wavelength | 365 [nm] |

| Temperature | RT to 250 [°C] |

| Pressure | 0 to 550 [psi] |

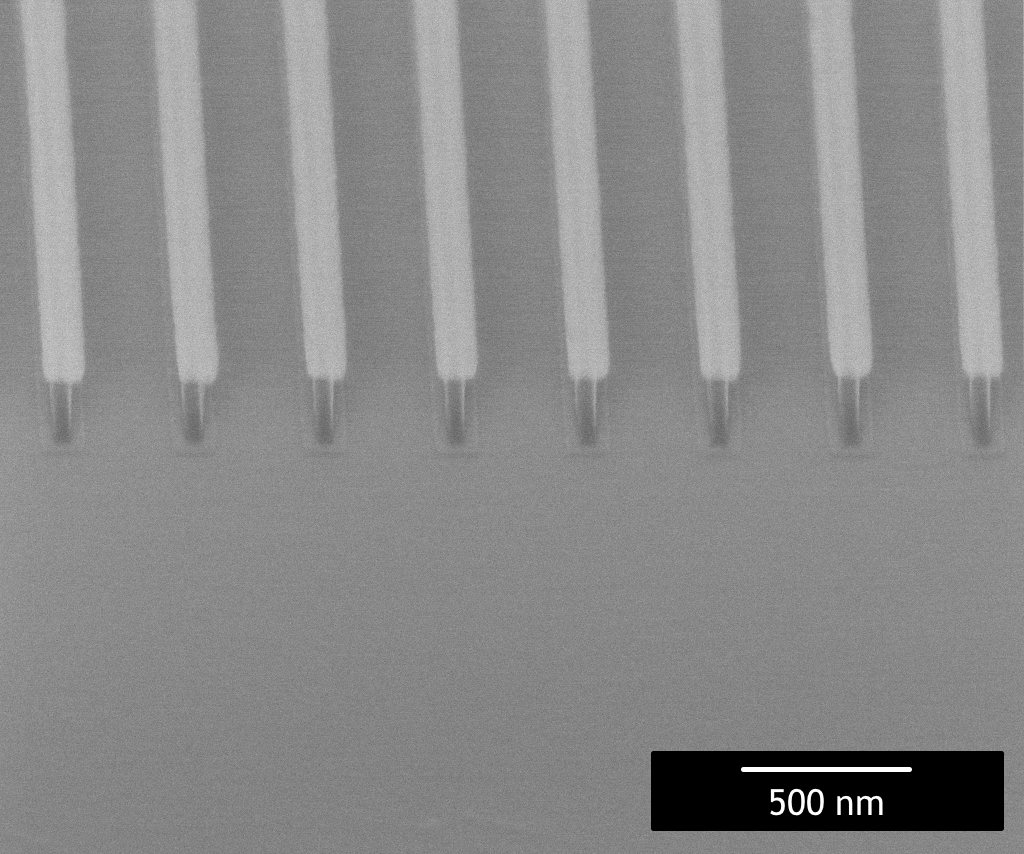

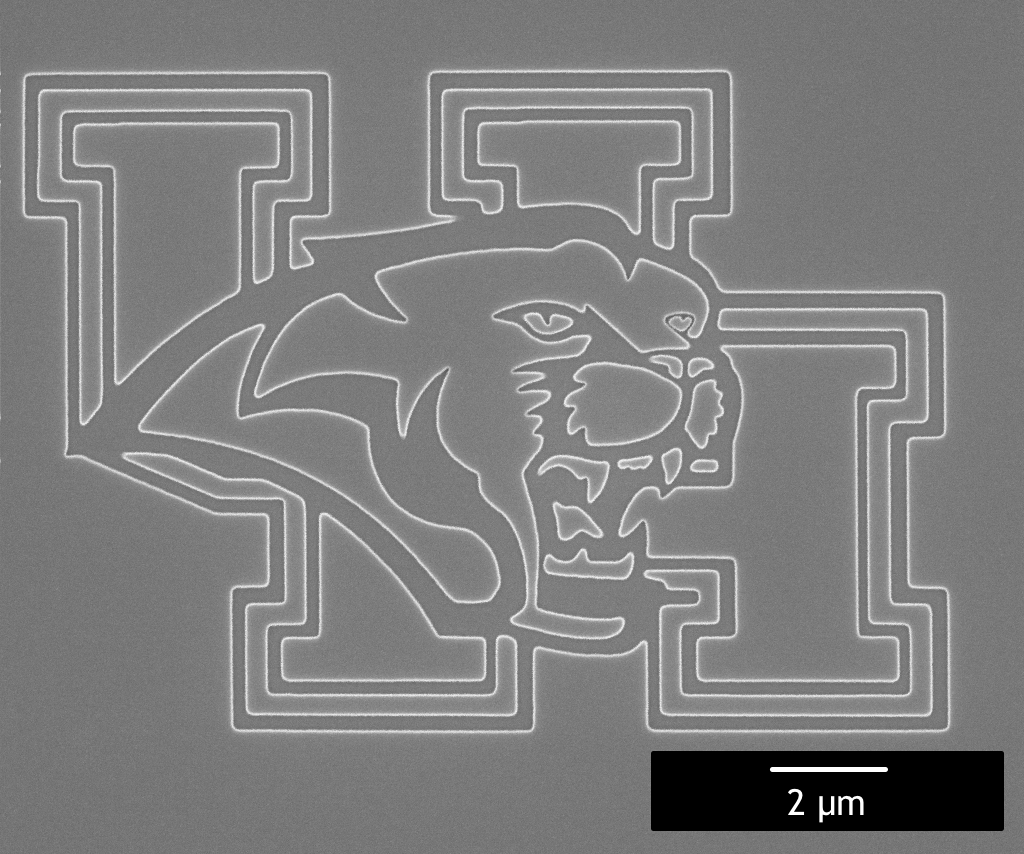

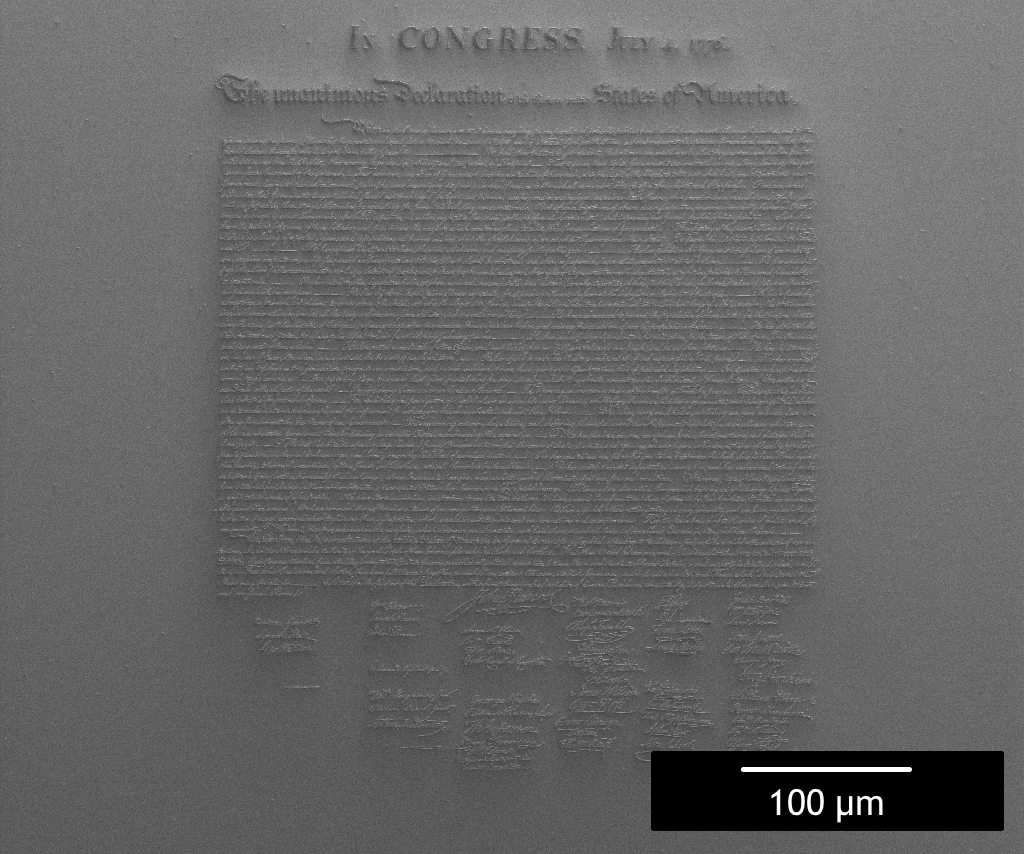

Examples

Core Technology

| Core Technology | Description |

|---|---|

| SOP: Nanonex NX-2004 | This document is the standard operating procedure (SOP) for the Nanonex NX-2004 nanoimprinter at UHNF. This SOP serves as a foundation for initial training and ensures that the equipment can be operated correctly, by everyone, the first time. |

| SSP: Nanonex NX-2004 | This is a service manual we developed for the Nanonex NX-2004 nanoimprinter at UHNF. This document ensures that any staff can effectively perform routine service or repairs effectively, quickly and at significantly lower cost. This document is restricted to equipment custodians. Contact us for access. |

| SiO2 Mold | Standard nanoimprint molds are expensive and there are currently no companies offering molds with custom patterns. Here we describe the procedure to fabricate nanoimprint molds in SiO2. This process works with all forms of SiO2 such as thermal oxide or fused silica wafer. |

| Tone Reversal | In thermal nanoimprint, a rigid mold pattern is imprinted into a thermoplastic polymer such as PMMA by pressing the mold into the polymer while applying heat. The heat softens the thermoplastic, allowing it to be displaced from the protruding areas in the mold. Nanoimprinting requires higher pressures and temperatures as the ratio of protrusions to cavities increases. This problem can be avoided by using this tone reversal process to transform cavities in the thermoplastic to protrusions. |

| Anti-Stick Coating | A nanoimprint mold must be protected with an anti-stick coating to prevent contamination by the imprint media. This process produces a teflon-like coating that is effective for molds with 100 [nm] minimum features. |

| Mold Replication | Nanoimprint molds are very expensive and are subject to extreme abuse during the imprint process. The master mold can be replicated to form many identical sub-master molds. |

| PMMA | PMMA is a thermoplastic that is imprinted at 500 [psi] and 150 [°C] |

| HSQ | HSQ is imprinted at 500 [psi] and room temperature |

| mr-I | mr-I is a thermoplastic that is imprinted at 500 [psi] and 90 [°C] |

Guide

| Guide | Description |

|---|