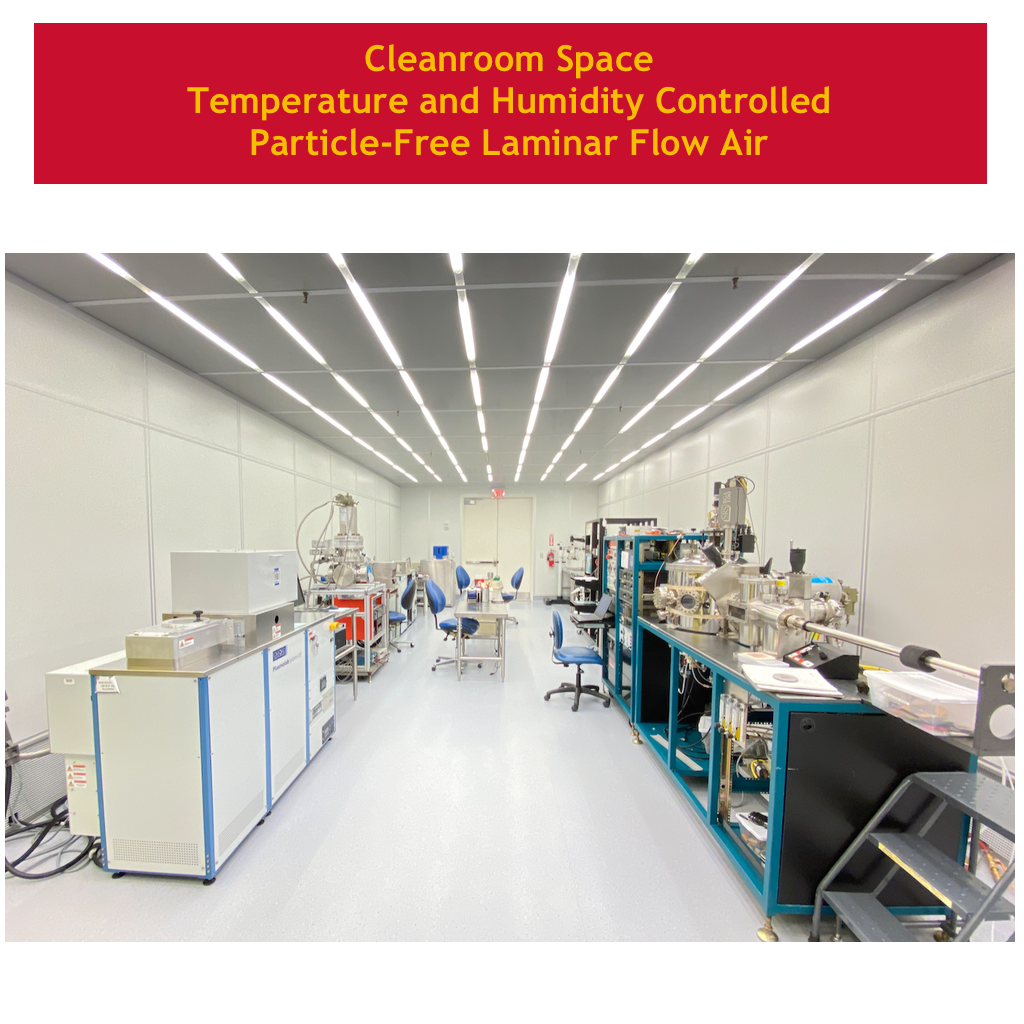

Cleanroom Facility

A cleanroom is a facility designed to maintain extremely low levels of particulates in the air. The level of cleanliness is quantified by the number of particles per cubic meter. The ambient outdoor air in a typical urban area contains approximately 35,000,000 particles that are 0.0005 mm or larger for each cubic meter. UHNF cleanroom maintain a cleanliness level of 35,000 particles for each cubic meter or better, equivalent to class 1,000 or ISO 6.

Cleanroom Environment Overview

The UH Nanofabrication Facility includes a 3,300 square foot cleanroom space. The cleanroom environment is needed to reliably fabricate microscopic devices for research and manufacturing. This is achieved by taking ambient air and moving it through three stages of conditioning and purification. The cleanroom provides and maintains the following specifications:

- Class 1,000 or cleaner air

- Temperature of 68°F within 1°F

- Humidity of 50% within 5%

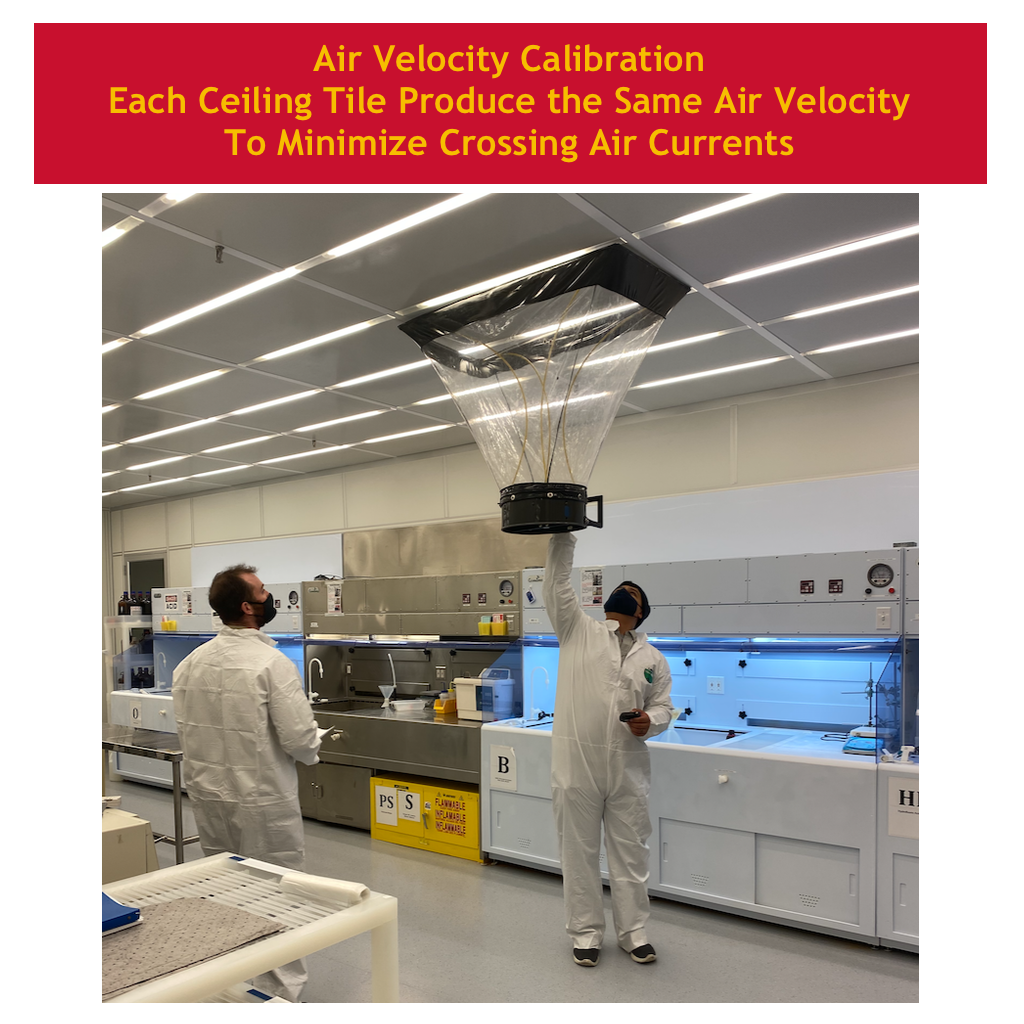

- Laminar Flow of 21 feet per minute (FPM) within 3 FPM

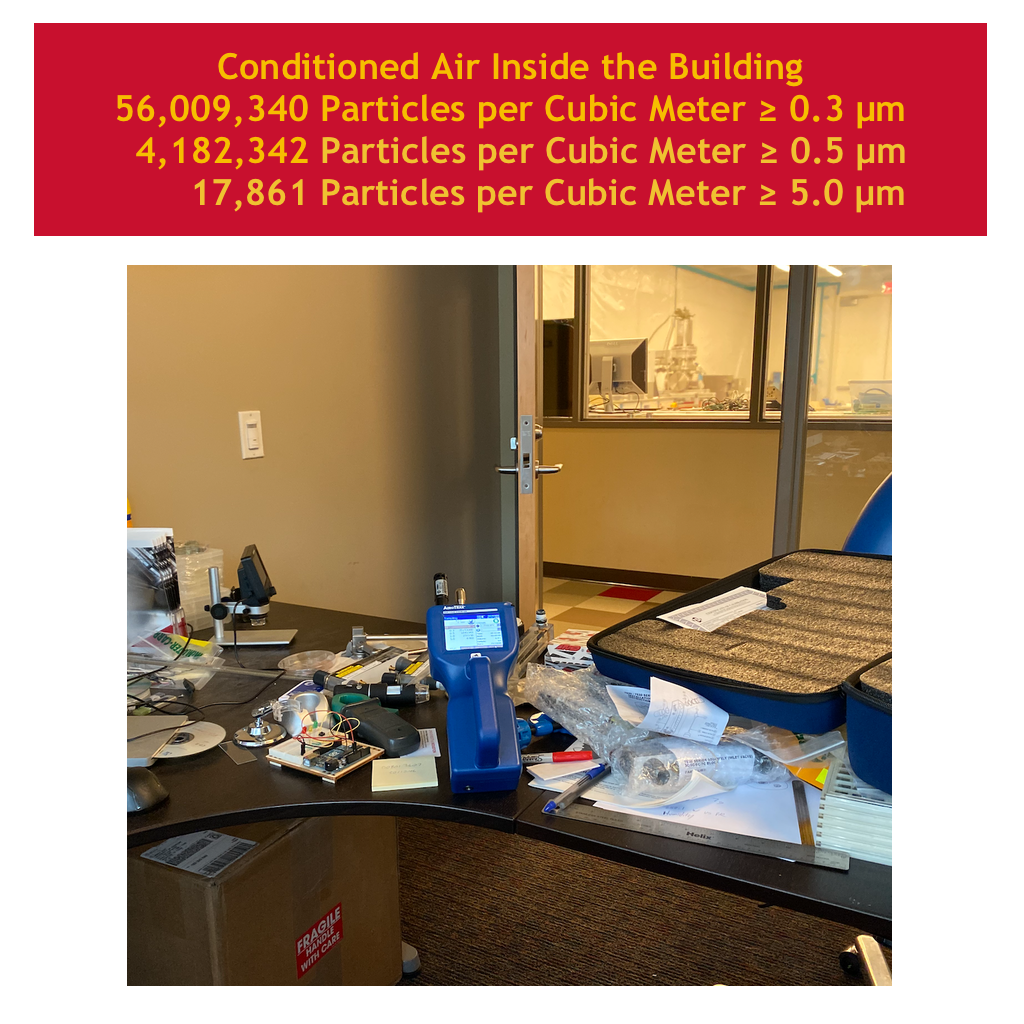

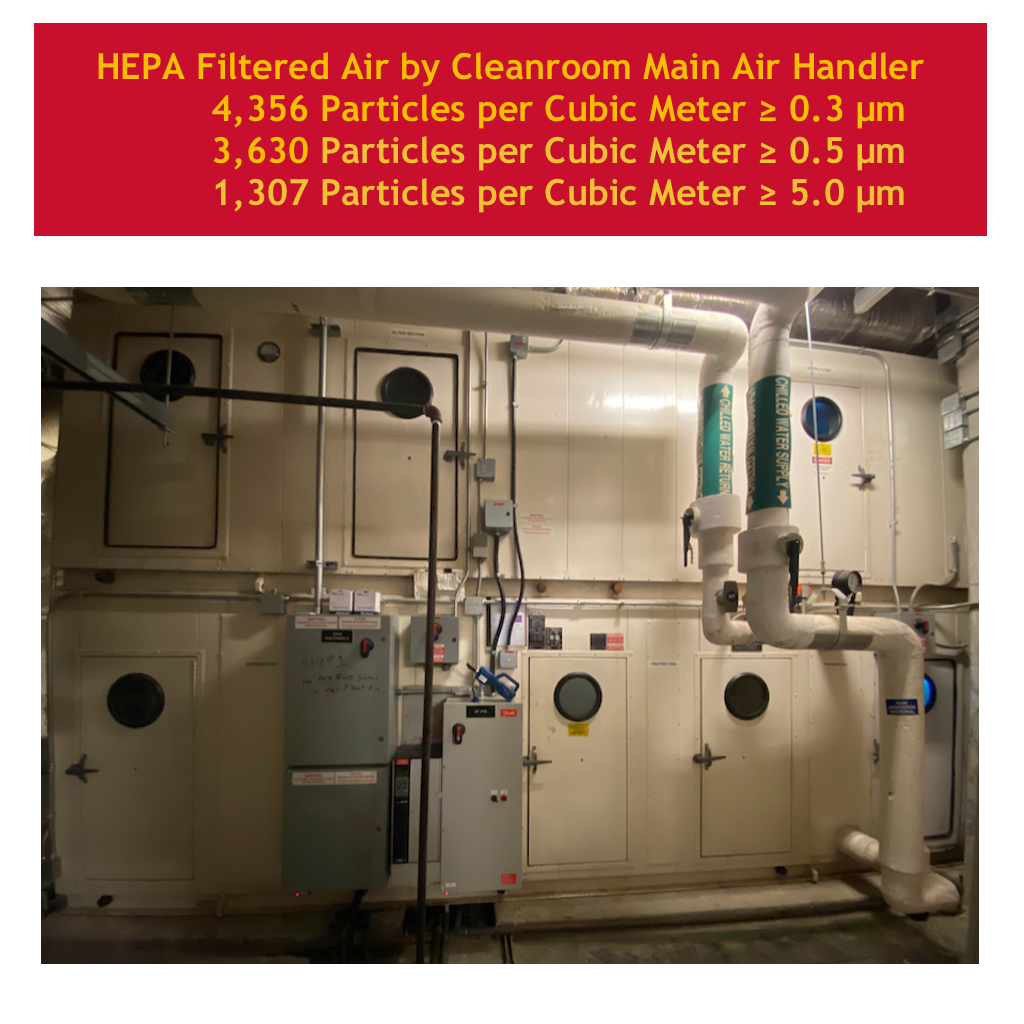

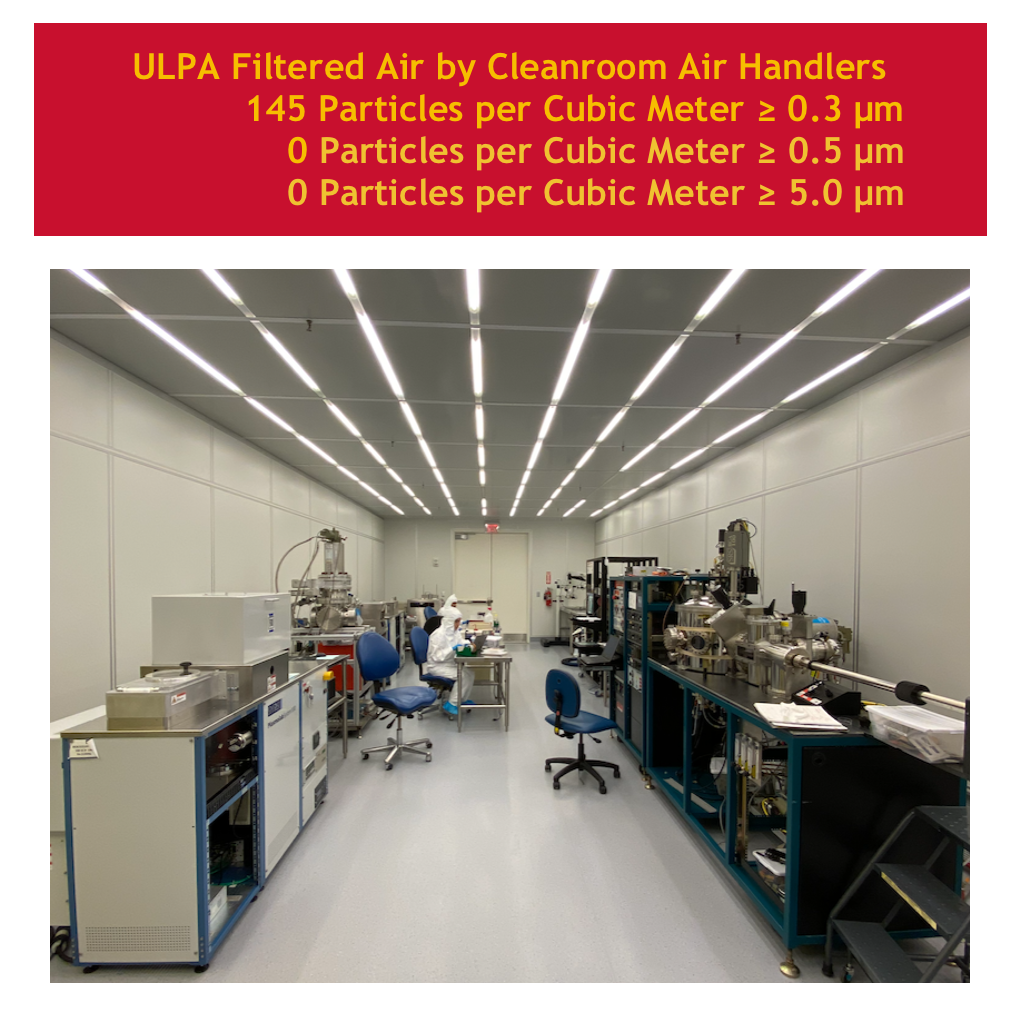

Air Purification System

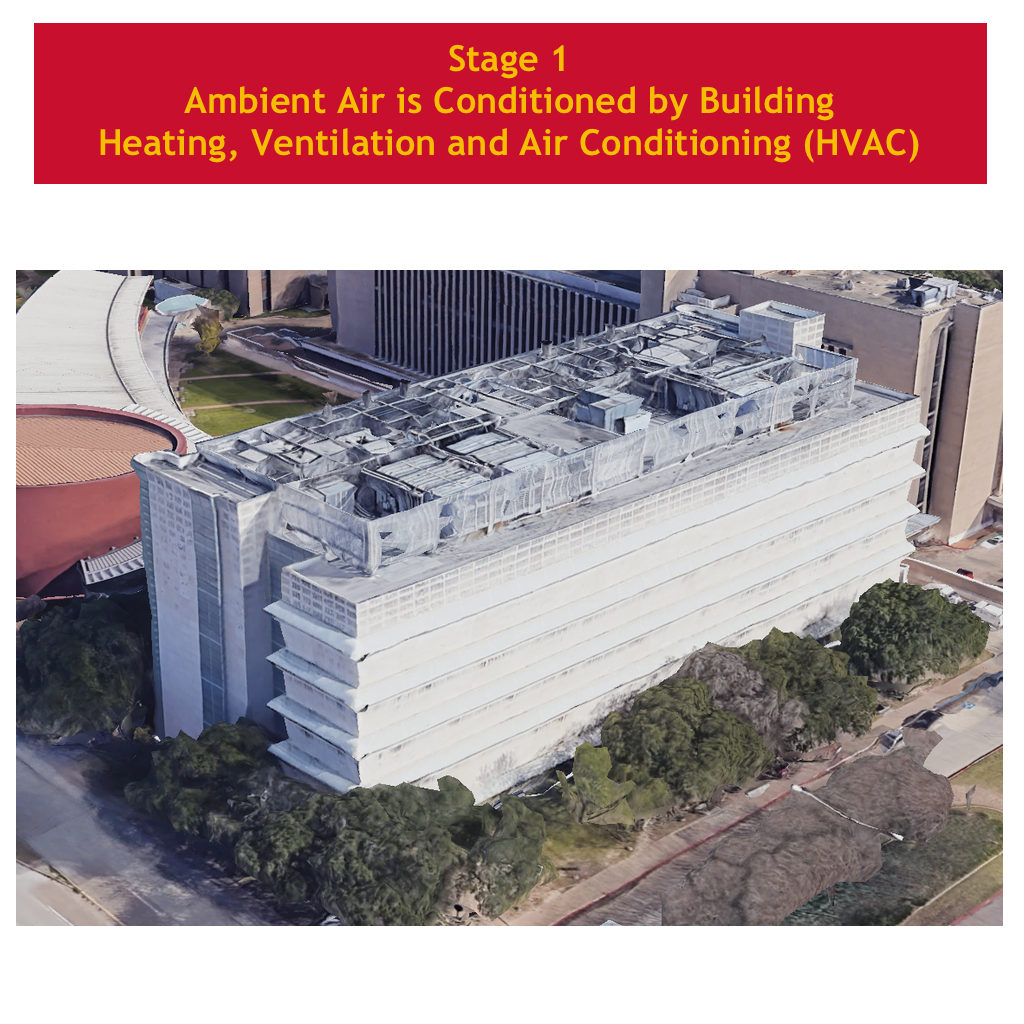

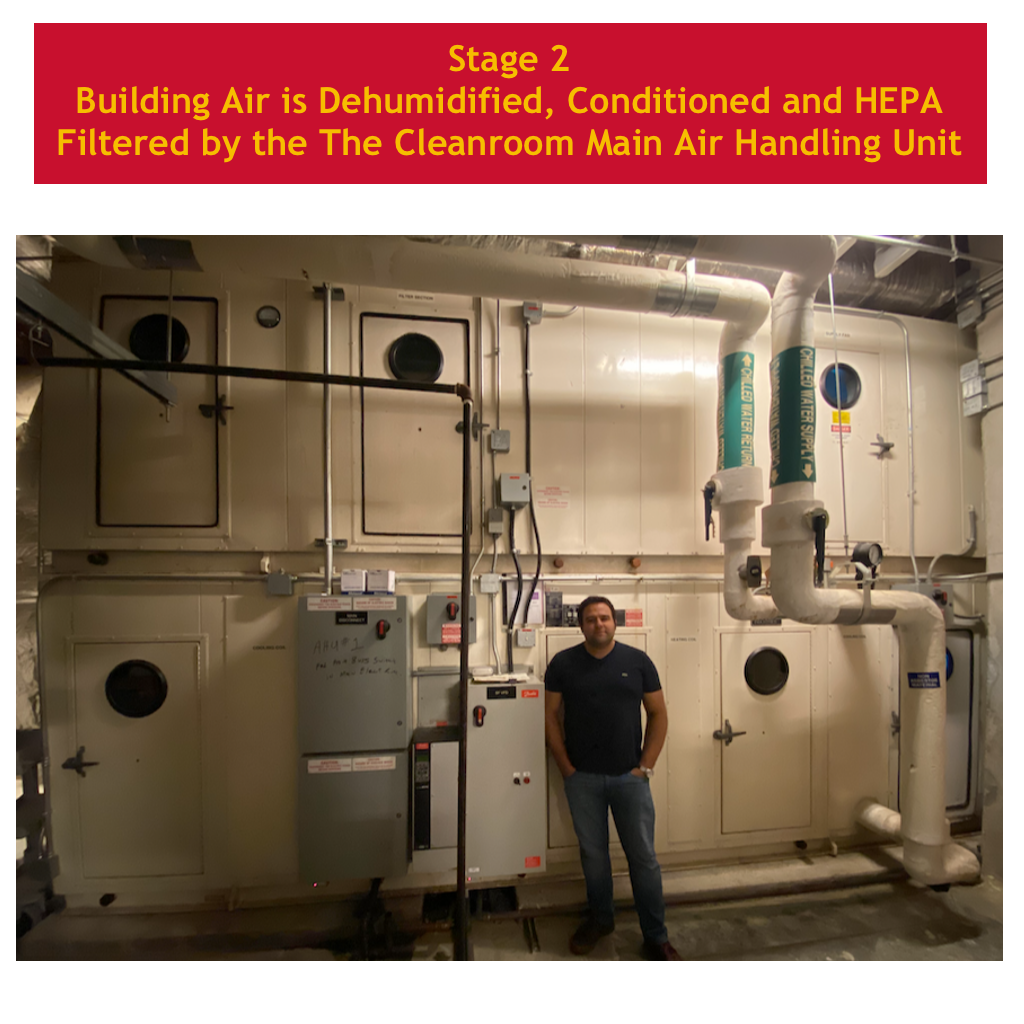

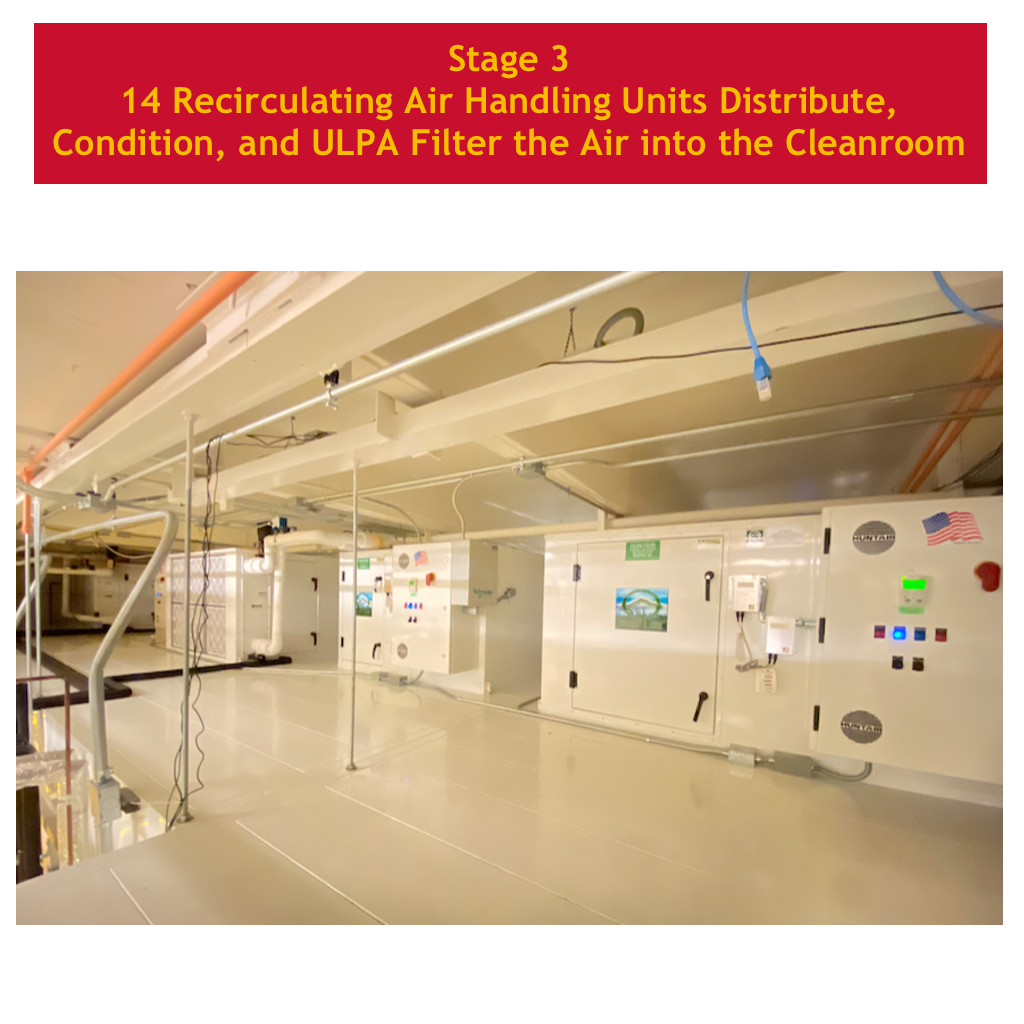

Ambient air is purified through a number of filters before entering the cleanroom. First, ambient air is drawn into the building’s heating, ventilation and air conditioning (HVAC) system, providing acceptable indoor air quality and comfortable working conditions. Next, the building air is processed by the cleanroom’s main HVAC system which further conditions the air (temperature and humidity) and reduces particulates by up 1000x with HEPA filters. Finally, the HEPA filtered air gets conditioned again and purified with ULPA filters by 14 recirculating air handling unit (RAHU). These 14 RAHU is distributed across the roof of the cleanroom to provide and maintain a class 1000 or cleaner air in every region of the cleanroom. Some of the used air gets exhausted, but most of it gets recycled by mixing with the incoming HEPA filtered air followed by reconditioning and purification through the 14 RAHU. This system completely replaces the air in the cleanroom at a rate of approximately 35 times per hour.

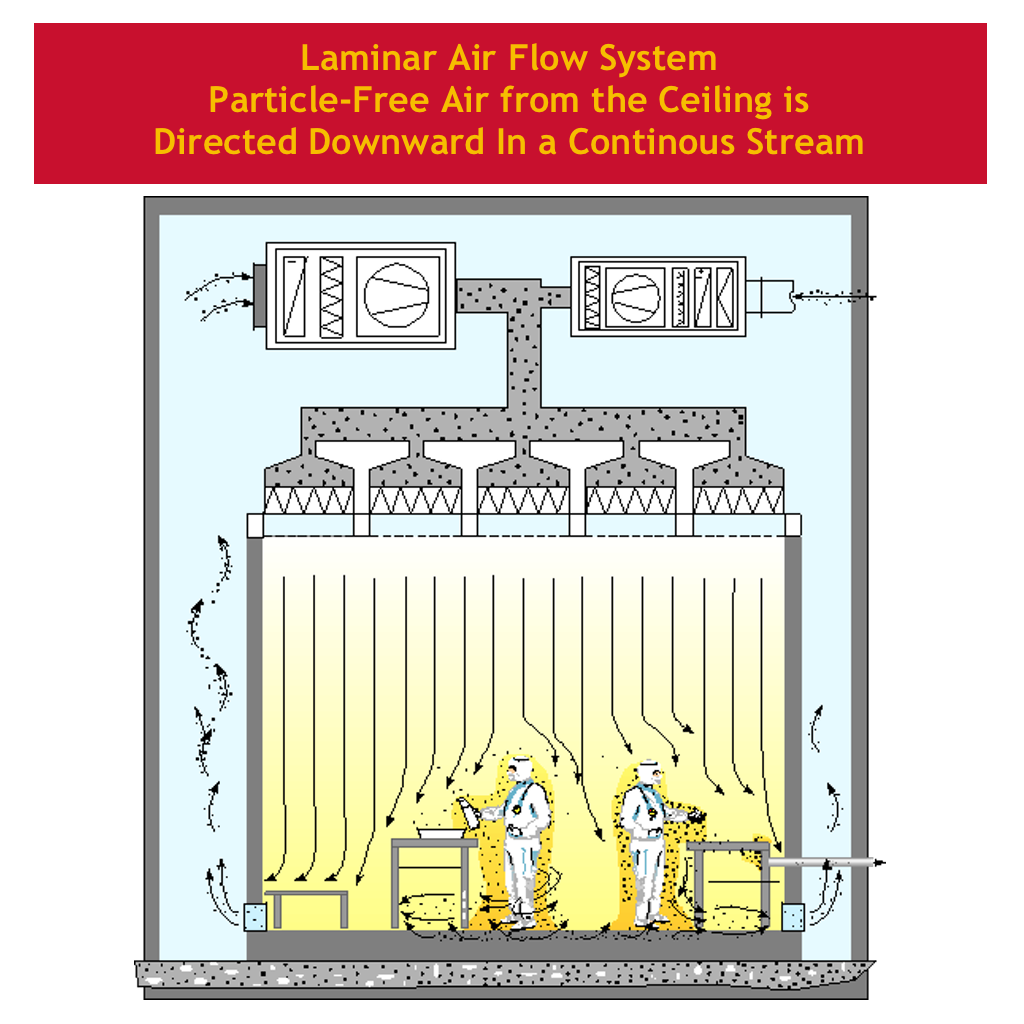

Laminar Flow Air

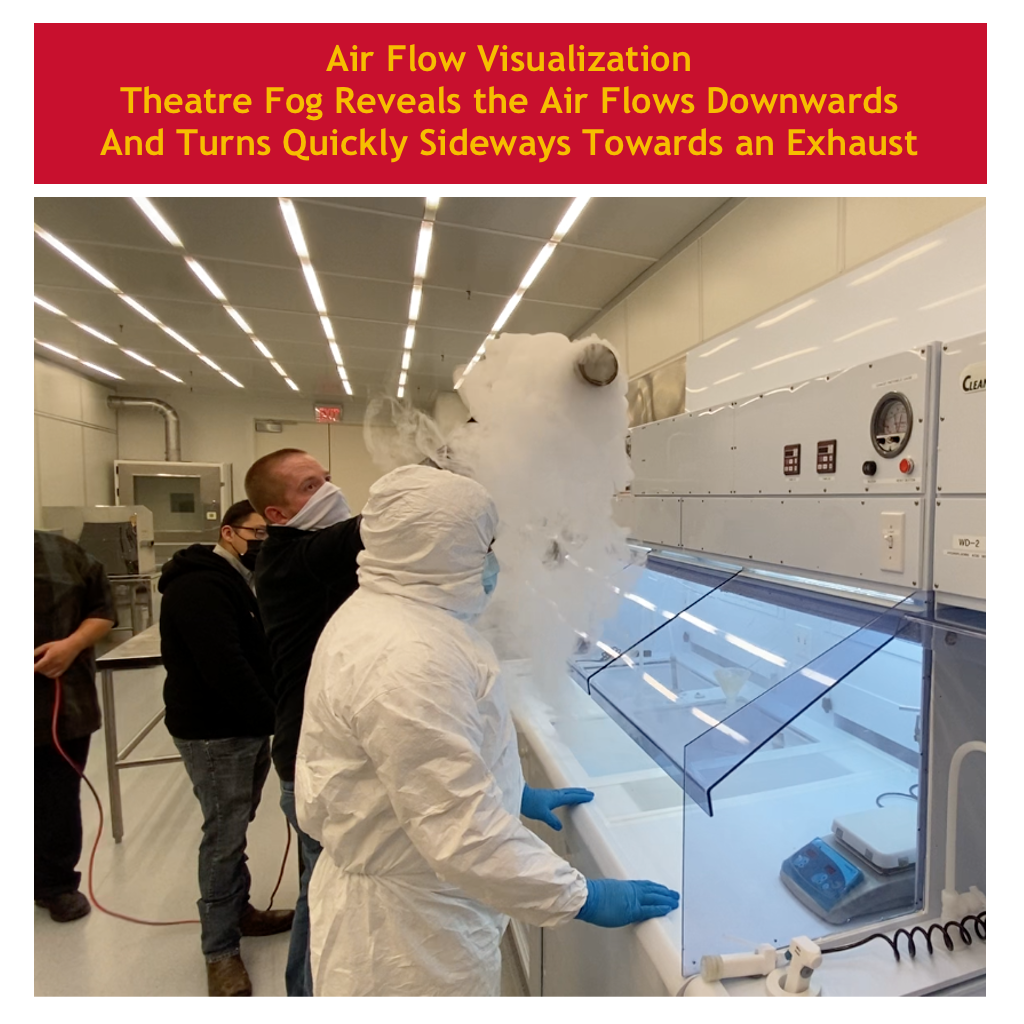

Samples remain particle-free as long as it is exposed only to particle-free air (first air). First air flows continuously from the ceiling in a straight downward path (laminar flow) towards the floor at a velocity of 21 feet per minute (FPM). The air then gets drawn towards sideways towards the exhaust grills on the wall by the floor. Most of the exhausted air gets conditioned and cleaned before returning to the cleanroom as first air again.

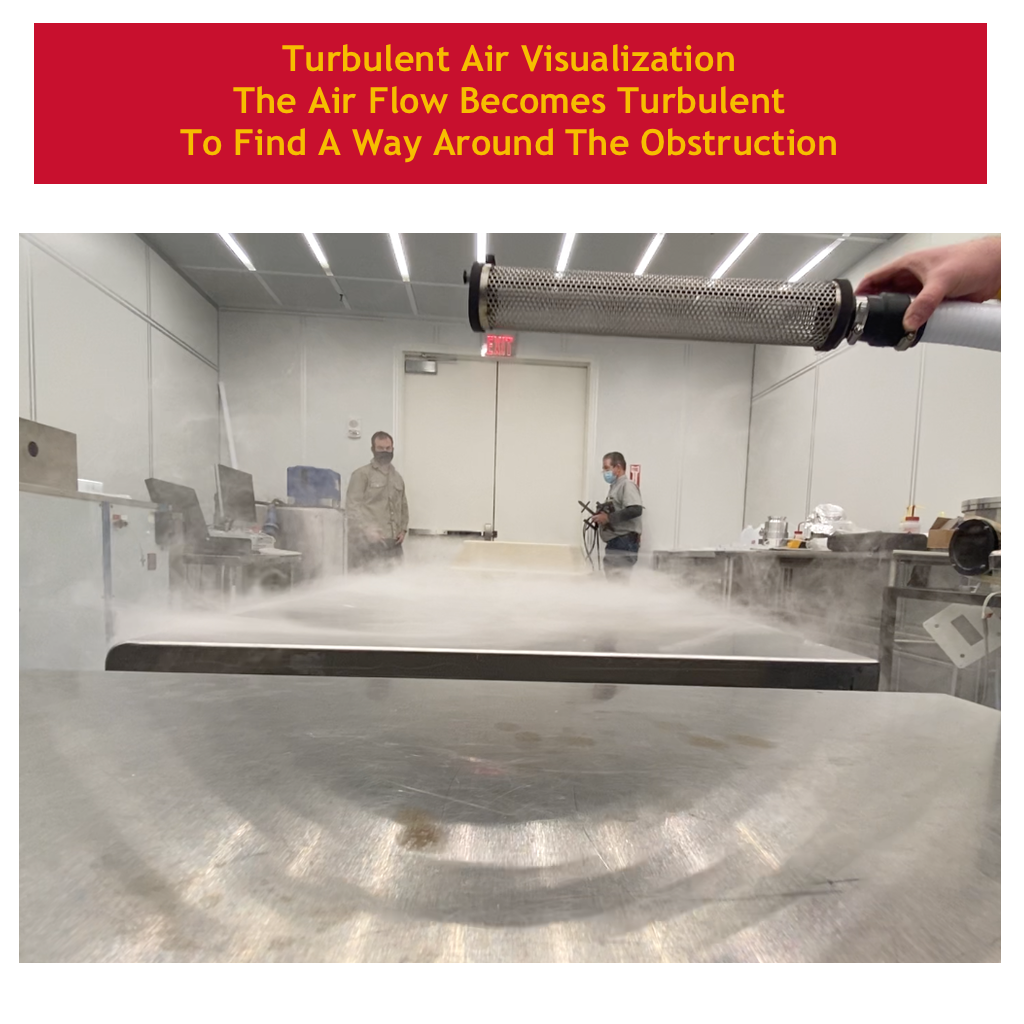

When the first air encounters an obstruction such as equipment, furniture, people, etc, the air flow becomes turbulent and can pick up particulates. People are responsible for most of the particles generated inside the cleanroom. This is why cleanroom users must wear cleanroom suits to contain the particulates from their clothes and body and refrain from making sudden movements. The average walking speed of 276 FPM, much faster than the first air velocity of 21 FPM, creates a long trail of turbulent air that can take up to a minute to recover.

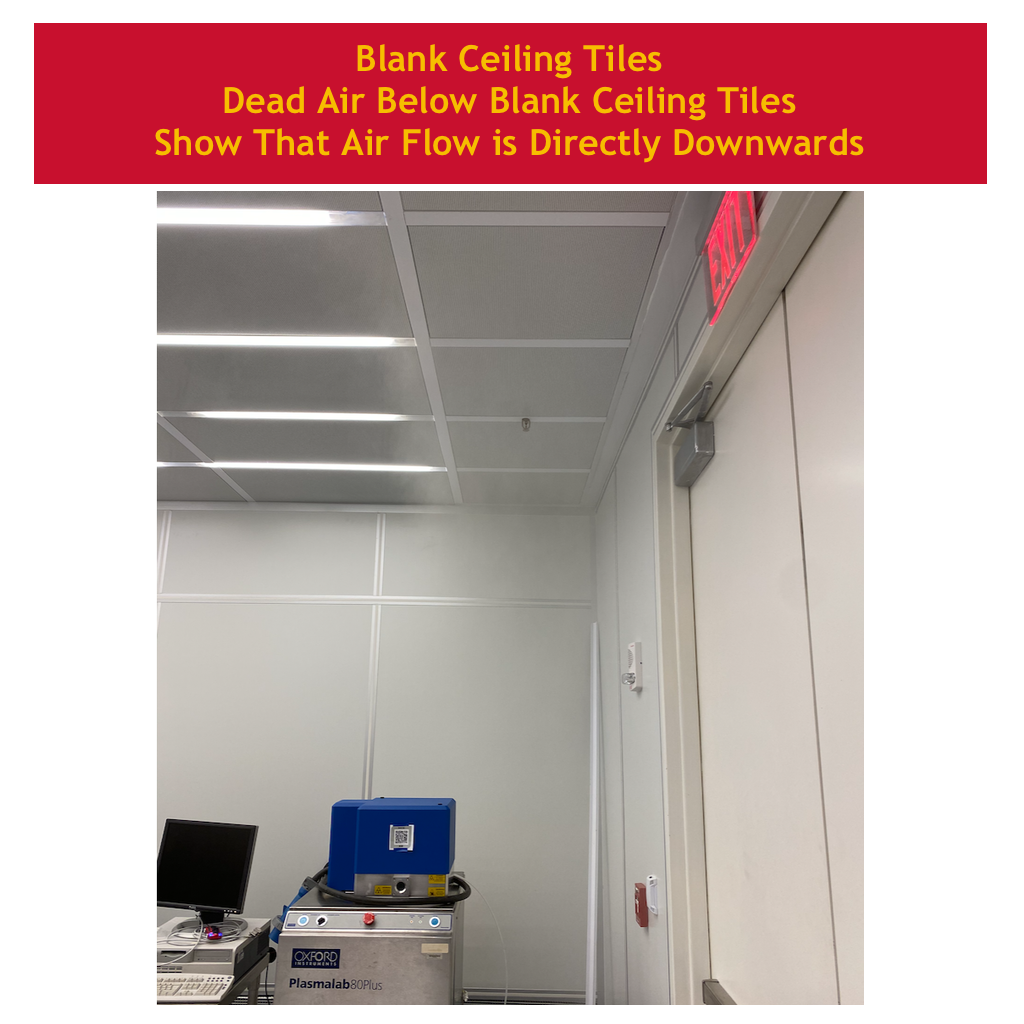

Air flow patterns in the cleanroom is visualized using a theatre fog machine. The fog show that the air flows straight downwards from the ceiling without any sideway motion. The air becomes turbulent when it encounters a surface and produces a 1 inch thick layer of dead air that doesn’t move. Dead air is also visible below blank ceiling tiles at the perimeter of the cleanroom.